Multi-stage condensation system for desulfurization flue gas

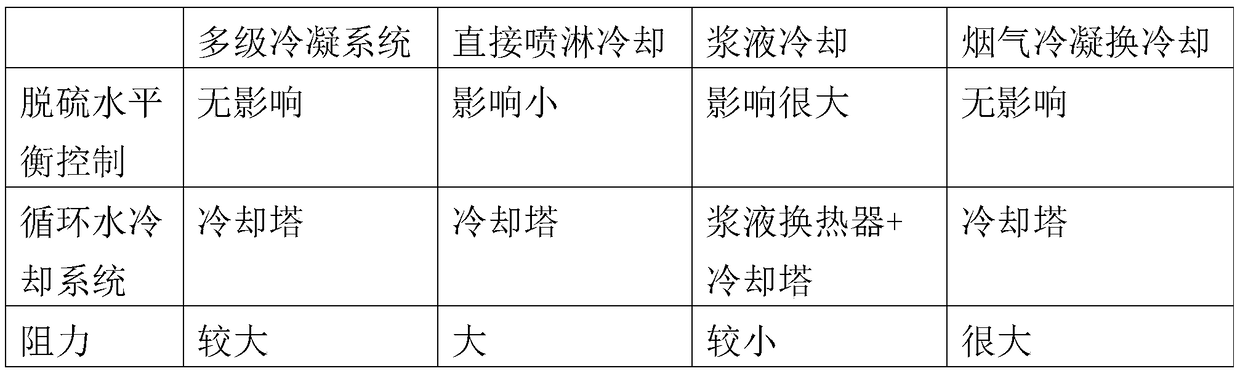

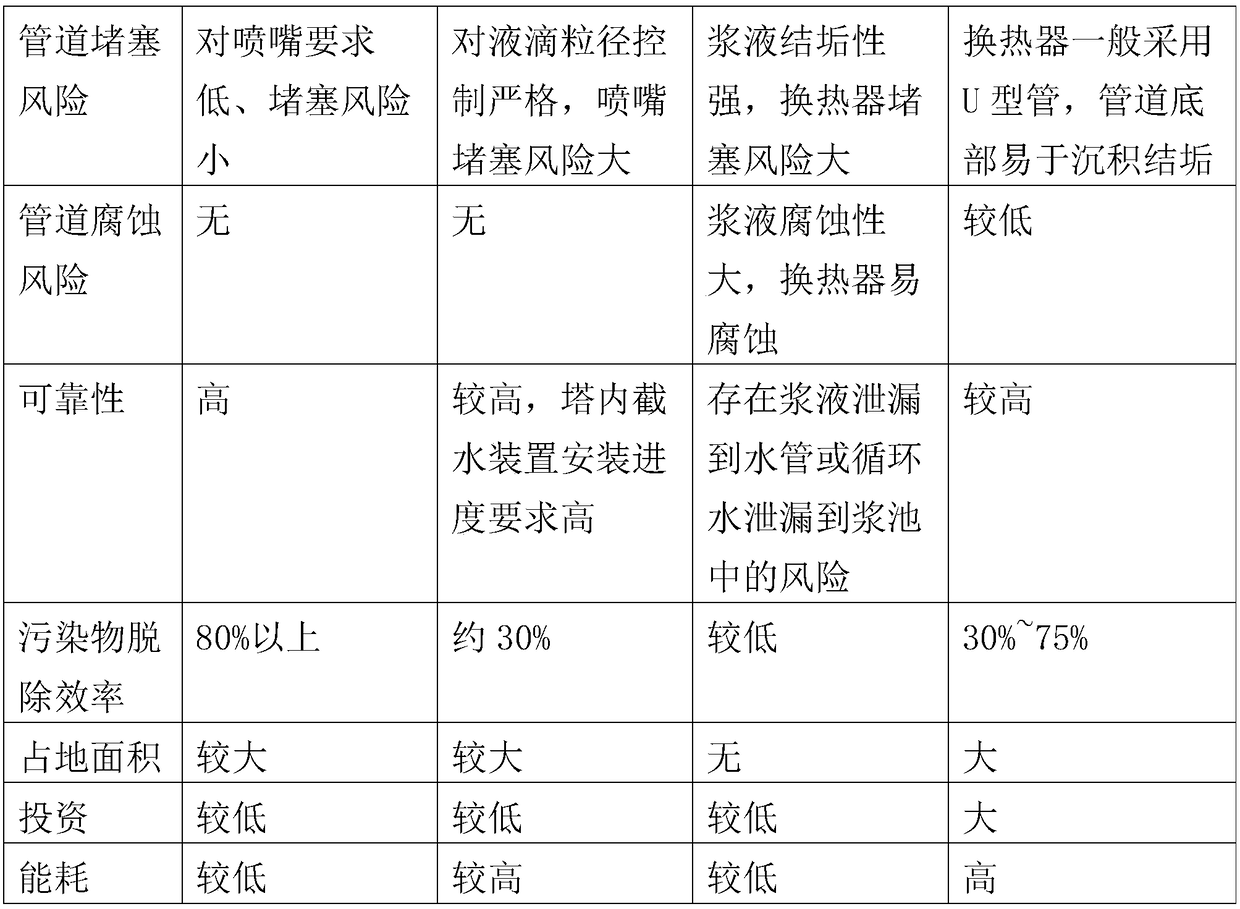

A flue gas condensation and condensation system technology, applied in steam condensation, multi-effect/separation condensation, gas treatment, etc., can solve the problems of limited cooling range, limited removal assistance, etc., to achieve extended contact time and area, low resistance , The effect of difficult water balance control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

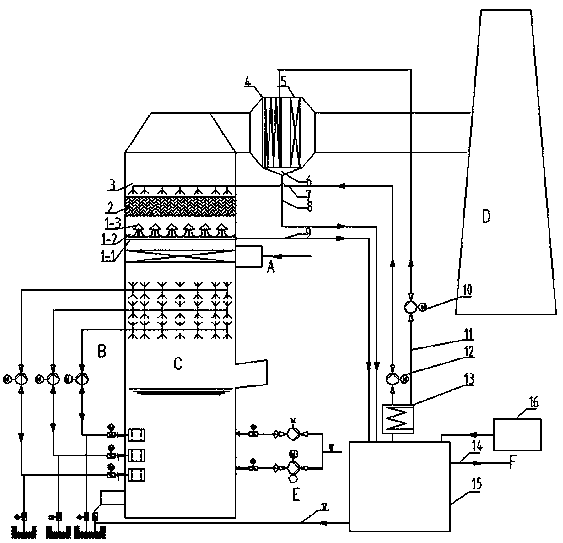

[0036] The desulfurization flue gas multi-stage condensation system of the present invention comprises three parts in sequence according to the flue gas flow direction: a spray flue gas cooling system arranged in the tower; a flue gas condensation phase change system connected to the flue; and a flue gas condensation phase change system arranged outside the tower The water circulation system, the flue gas condensing heat exchanger adopts the flue type flue gas condensing heat exchanger.

[0037] The flue gas spray cooling system is arranged above the demister in the desulfurization absorption tower, and includes, from bottom to top, water recovery device (1), water distribution layer (2) and spray device (3);

[0038] The flue gas condensation phase change system includes a flue gas condensation heat exchanger (4) and a demister (5) arranged according to the flue gas flow direction;

[0039] The water circulation system includes a circulating water cooling system (14), a water...

Embodiment 2

[0043]In this example, the further design is that the flue gas condensation phase change system also includes a liquid collection tank (6), the flue gas condensation heat exchanger (4) and the demister (5) are arranged front and back, and the liquid collection tank (6) is arranged in The bottom of the two is used to collect the condensed water effluent collected by the flue gas condensation heat exchanger (4) and the mist eliminator (5). The liquid collection tank (6) recovers the liquid droplets formed by condensation and the circulating cooling water, and enters the water tank (15) for reuse through the recovery water pipeline (8).

Embodiment 3

[0045] In this example, the further design is that the water distribution layer (2) adopts a layer of folded plate device, which can form a water distribution layer on the board and form a group of water films on both sides to expand the condensed water and smoke. The contact time and area are improved, and the efficiency of pollutant collection is improved at the same time. The flue gas passes through two layers of water film. Improve the removal efficiency of pollutants such as smoke and dust, and reduce the pressure on the dust removal equipment before desulfurization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com