A visible and near-infrared photoresponsive cqds-znin 2 the s 4 -Preparation method of biocl ternary heterojunction

A near-infrared light-responsive, heterojunction technology, used in catalyst activation/preparation, chemical instruments and methods, illumination water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

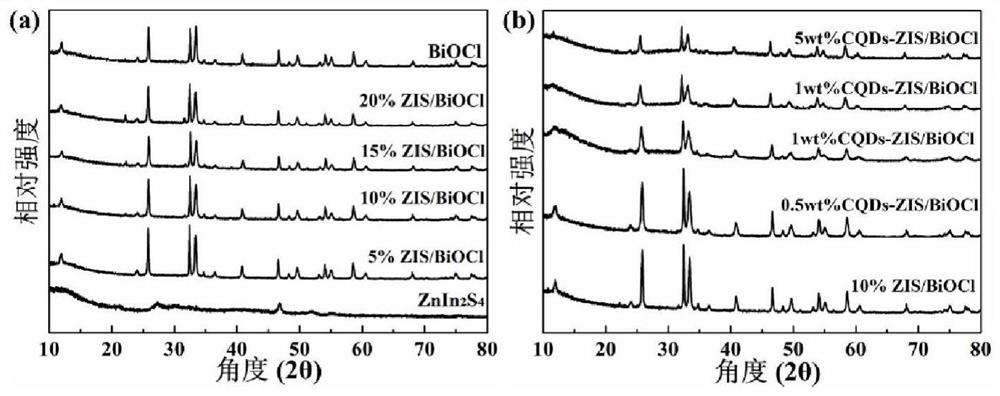

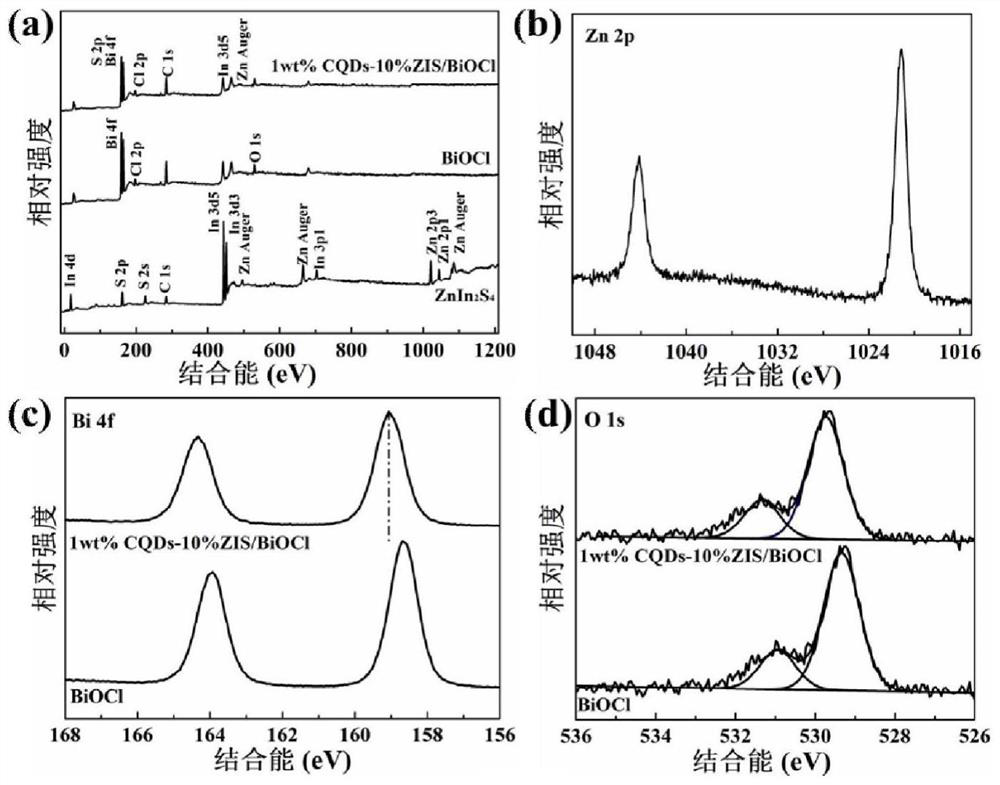

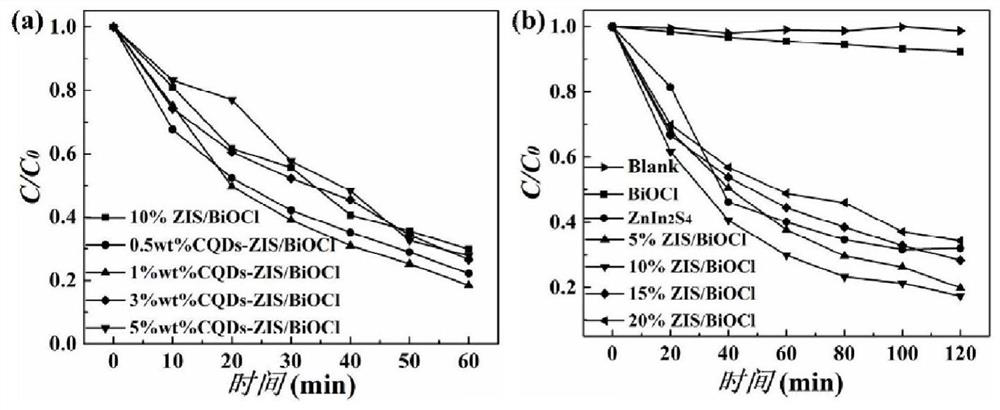

[0032]Visible and near infrared light response CQDS-Znin2S4-Biocl three-dimensional heterojunction method, including the following steps:

[0033]1) Preparation Znin2S4catalyst of light

[0034]ZnCl2, INCL3· 4h2O and thioacetamide were dissolved in deionized water at a ratio of 1: 2: 6, stirred for 15-30 min, then transferred to the hydrothermal kettle at 200 ° C for 22-26 h. The powder after the reaction was washed three times with water and ethanol, and 100-150 rpm was centrifuged for 3-5 min, and the dried 10-18 hours in the blower drying tank, thereby gave Znin 2S4 monomer;

[0035]2) Preparation of CQDS photocatalysts

[0036]The two substances of hydrated citric acid and ethylenediamine were dissolved in deionized water in molar ratio of 1: 1, and stirred for 5-10 min, then the above suspension was transferred to 25 mL of hydrothermal kettle heated to 180 ° C, maintained 3 -6 h. The powder after the reaction was washed three times with water and ethanol, and 100-150 rpm was centrifuged fo...

Embodiment 1

[0043]Example 1: Preparation Znin2S4monomer.

[0044]136mg ZnCl2, 586mg of INCL3· 4h2O and 460 mg of thiionaceramide were added to 70 ml of deionized water, stirred for 30 minutes, then transferred to 100 ml of hydrothelips at 200 ° C for 24 h. The powder after the reaction was washed three times with water and ethanol, and the centrifugation was centrifuged for 5 min, and dried at 60 ° C in the blast drying tank to obtain Znin.2S4monomer.

Embodiment 2

[0045]Example 2: Preparation of CQDS photocatalysts.

[0046]1.05 mg of citric acid and 0.335 ml of diethylenediamine were dissolved at 15 ml of deionized water, stirred for 10 min, and then transferred to 25 ml of hydrothermal kettle to 180 ° C for 5 h. The powder after the reaction was washed three times with water and ethanol, 100 rpm centrifuged for 5 min, and dried at 60 ° C in the blower drying tank to obtain a CQDS monomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com