Microfluidic device and method for detecting content of macromolecules in non-Newtonian fluid

A non-Newtonian fluid and microfluidic device technology, applied in chemical instruments and methods, laboratory containers, analytical materials, etc., can solve the problems of high requirements for fluorescein and complicated operation, and achieve simple operation, simple method, Easy to make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

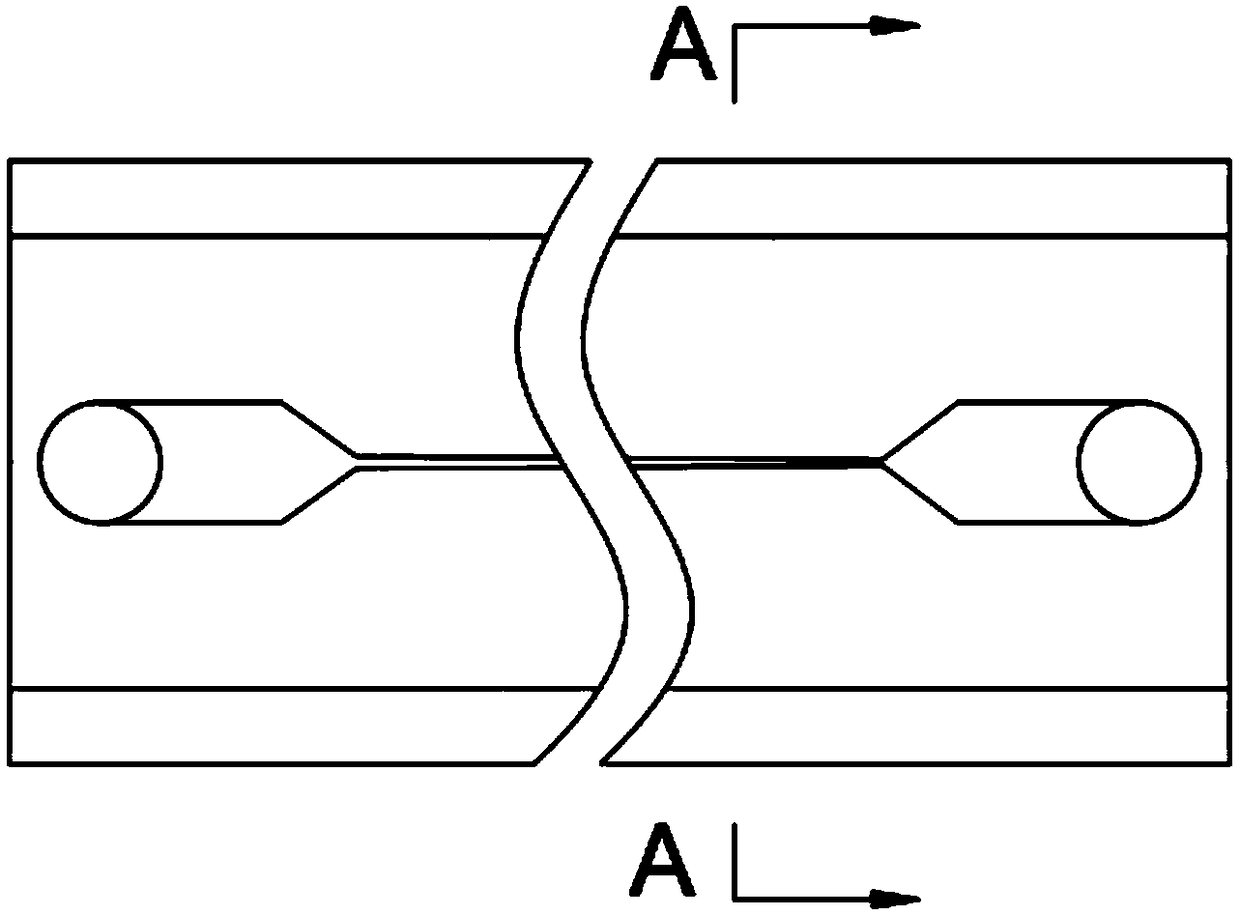

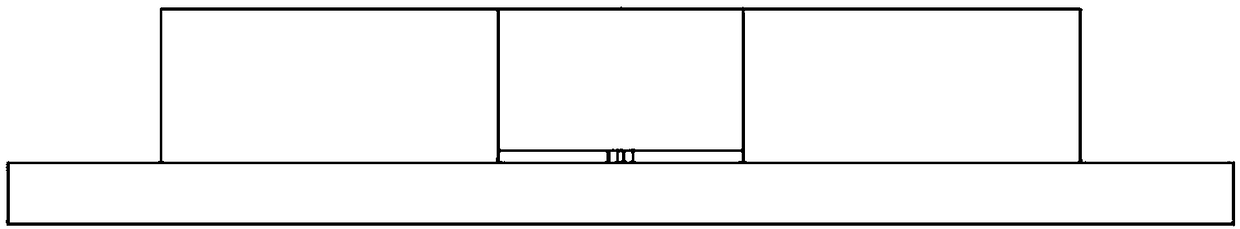

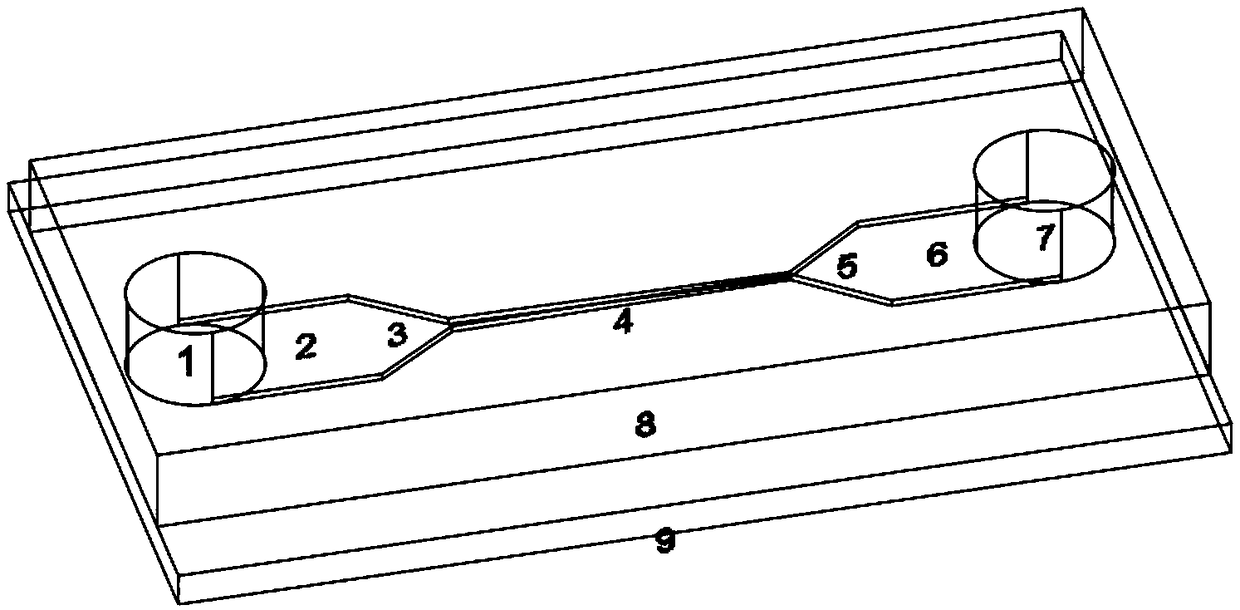

[0024] Such as Figure 1 to Figure 3 As shown, the present invention is a microfluidic device for detection of high molecular content in non-Newtonian fluids. The device is processed by standard soft lithography. The slide layer 9 is composed of; the cover sheet layer 8 is sequentially connected with a target sample solution adding area 1, an entrance observation area 2, an entrance contraction area 3, a tapered microchannel 4, an exit expansion area 5, and an exit observation area 6 and the microchannel formed by the liquid discharge area 7; the sample liquid addition area 1, the entrance observation area 2, the entrance contraction area 3, the tapered microchannel 4, the outlet expansion area 5, the exit observation area 6 and the liquid discharge area 7 is located at the central position where the cover sheet layer 8 and the slide 9 are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com