A kind of sludge continuous crushing pretreatment equipment

A pretreatment and sludge technology, applied in grain treatment, solid separation, chemical instruments and methods, etc., can solve the problems of low bearing capacity, land occupation, soil and groundwater environmental pollution, etc., and achieve the effect of fine screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

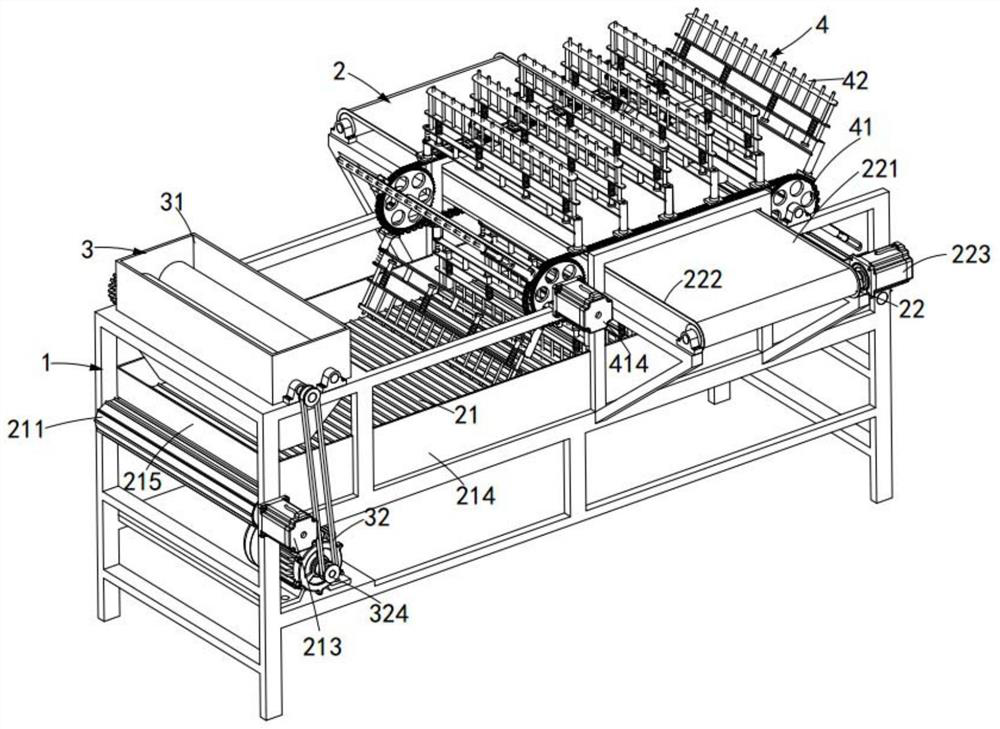

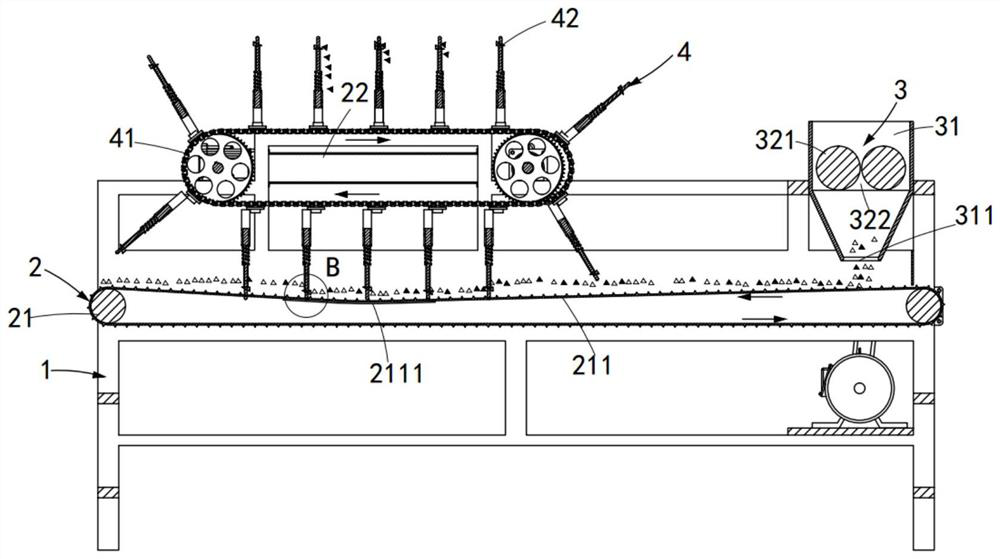

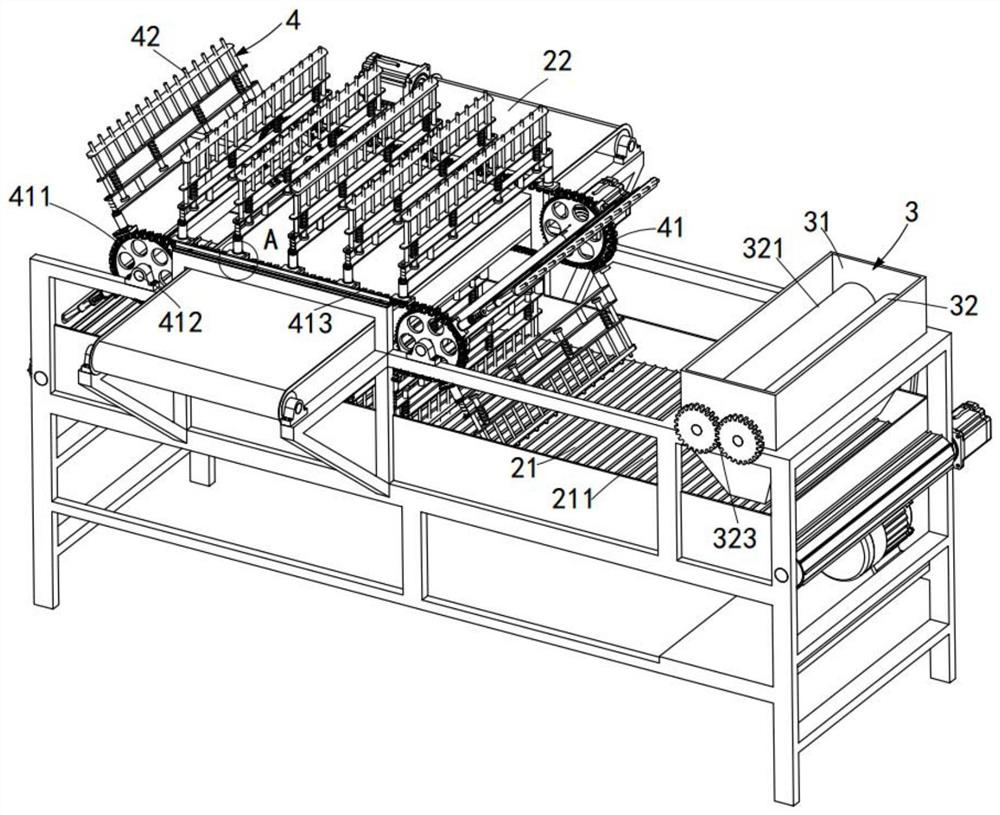

[0061] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a sludge continuous crushing pretreatment equipment includes a frame 1, and also includes:

[0062] The conveying mechanism 2, the conveying mechanism 2 is arranged on the frame 1, it includes a first conveying assembly 21 and a second conveying assembly 22 arranged in a staggered manner, and the first conveying assembly 21 is located on the second conveying assembly 22, the first conveying assembly 21 includes a first conveyor belt 211 for transporting sludge, the first conveyor belt 211 is rotatably set on the frame 1, and the first conveyor belt 211 is provided with Mud depressions 2111;

[0063] A crushing mechanism 3, the crushing mechanism 3 is arranged above the feeding end of the first conveying assembly 21, and it includes a material box 31 and a crushing assembly 32, and the crushing assembly 32 is arranged in the material box 31; and

[0064] The screening mechanism 4, the screening mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com