Method of preparing Y molecular sieve by waste MTP catalyst and application of waste MPT catalyst

A catalyst and molecular sieve technology, which is applied in the directions of fauhhedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of reduced MTP catalyst activity, waste of silicon and aluminum species, complicated regeneration process, etc., and achieves simplified steps, The effect of saving resources and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

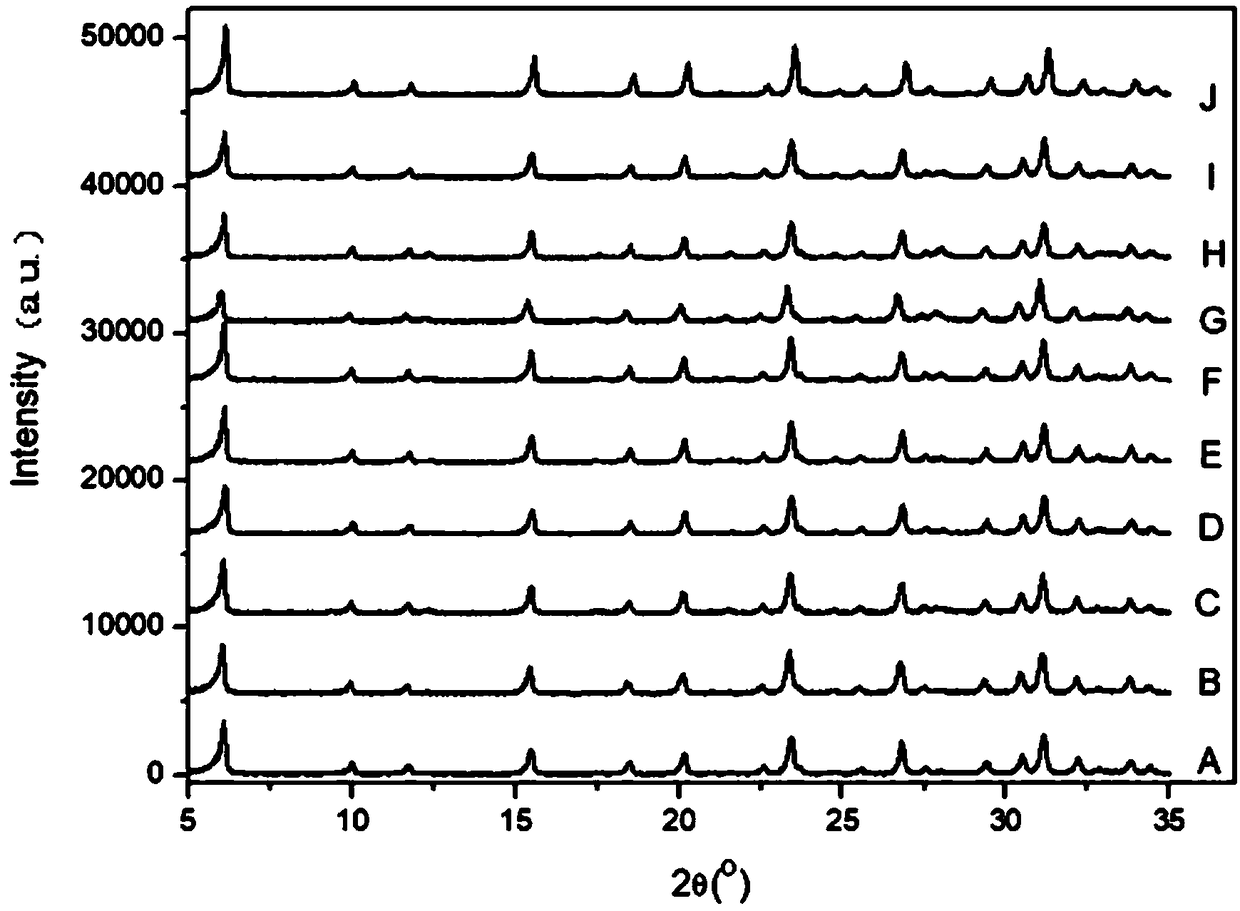

[0039] Embodiment 1 waste MTP catalyst prepares Y molecular sieve

[0040] In this example, the silicon / aluminum molar ratio of the spent MTP catalyst is 2, and the coke formation rate is 4%. The method for preparing Y molecular sieve by waste MTP catalyst comprises the steps:

[0041] (1), take 40g of waste MTP catalyst fine powder and add 200g of concentration into 5mol / L sodium hydroxide solution, control the temperature at 50°C and stir for 3h to obtain a slurry;

[0042] (2), add 12g directing agent and 300g water to the slurry obtained in step (1), stir for 1h to obtain a suspension, then transfer the suspension to a hydrothermal kettle for crystallization, and control the crystallization temperature to 90 ℃, the crystallization time is 10h, and the crystallized product is obtained after the crystallization is completed;

[0043] (3) The crystallized product of step (2) is cooled and washed until neutral, then dried to obtain a powder, and the powder is calcined at 500...

Embodiment 2

[0047] Embodiment 2 Waste MTP catalyst prepares Y molecular sieve

[0048] In this example, the silicon / aluminum molar ratio of the spent MTP catalyst is 2, and the coke formation rate is 4%. The method for preparing Y molecular sieve by waste MTP catalyst comprises the steps:

[0049] (1), take 40g of waste MTP catalyst fine powder and add 200g of concentration into 1mol / L sodium hydroxide solution, control the temperature at 50°C and stir for 3h to obtain a slurry;

[0050] (2), add 12g directing agent and 300g water to the slurry obtained in step (1), stir for 1h to obtain a suspension, then transfer the suspension to a hydrothermal kettle for crystallization, and control the crystallization temperature to 90 ℃, the crystallization time is 10h, and the crystallized product is obtained after the crystallization is completed;

[0051] (3) The crystallized product of step (2) is cooled and washed until neutral, then dried to obtain a powder, and the powder is calcined at 600...

Embodiment 3

[0055] Embodiment 3 waste MTP catalyst prepares Y molecular sieve

[0056] In this example, the silicon / aluminum molar ratio of the spent MTP catalyst is 3, and the coke formation rate is 6%. The method for preparing Y molecular sieve by waste MTP catalyst comprises the steps:

[0057] (1), take 40g of spent MTP catalyst fine powder and add 800g of concentration into 1mol / L sodium hydroxide solution, control the temperature at 60°C and stir for 2h to obtain a slurry;

[0058] (2) Add 24g of directing agent and 600g of water to the slurry obtained in step (1), stir for 1 hour to obtain a suspension, then transfer the suspension to a hydrothermal kettle for crystallization, and control the crystallization temperature to 150°C , the crystallization time is 15h, and the crystallized product is obtained after the crystallization is completed;

[0059] (3) The crystallized product of step (2) is cooled and washed until neutral, then dried to obtain a powder, and the powder is calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com