A flame retardant extrusion grade pc/abs composite material

A composite material, extrusion-grade technology, applied in the field of polymer material modification, can solve the problems of material toughness to be improved, difficult to slice, difficult to plastic molding, etc. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The application continues to provide a method for preparing the flame-retardant extrusion grade PC / ABS composite material, comprising the following steps:

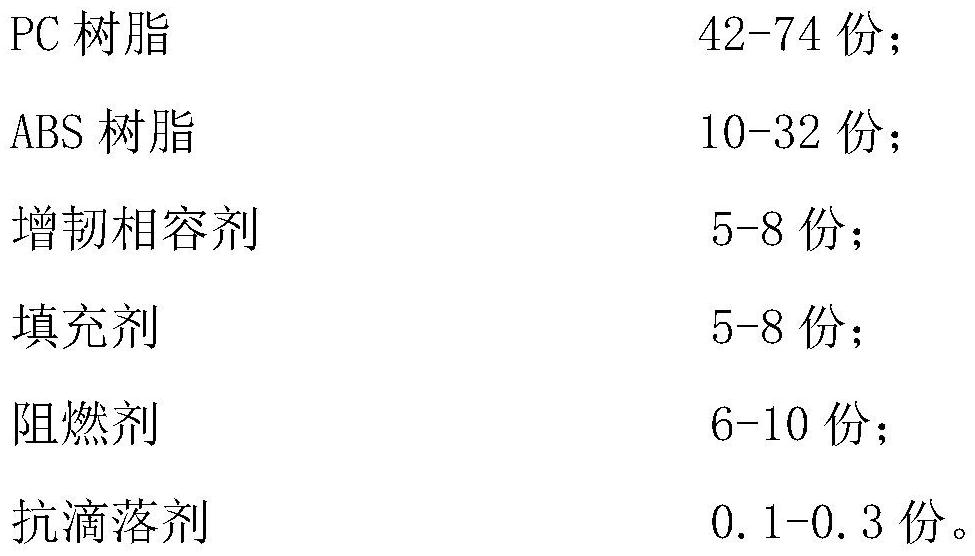

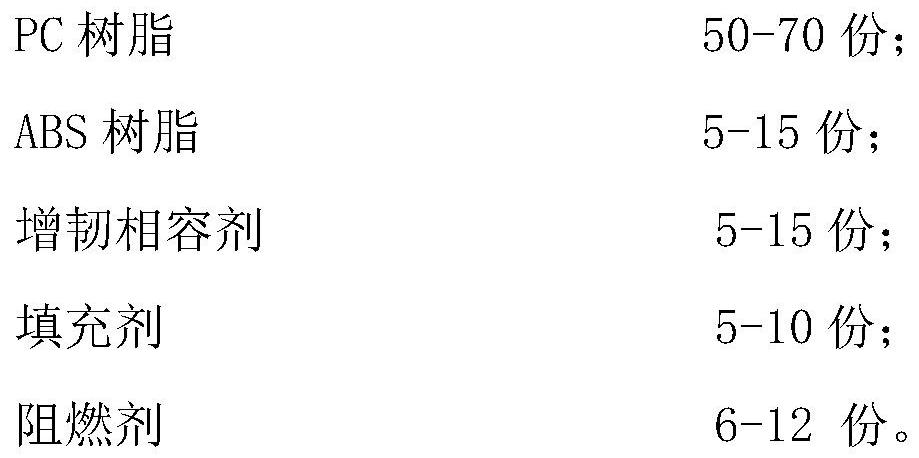

[0030] Step 1: Weigh 42-75 parts of PC resin, 14-35 parts of ABS raw powder, 5-10 parts of toughening compatibilizer, 5-10 parts of filler, 6-10 parts of flame retardant, Dropping agent 0.1-0.3 parts.

[0031] Step 2: Mix the above ingredients in a medium speed mixer for 3-7 minutes.

[0032] Step 3: Then melt and extrude the components mixed in step 2 through a twin-screw extruder, and granulate; wherein, the processing temperature of the twin-screw extruder is 210-260°C, and the conveying time of the mixture in the screw is 10-30 seconds.

[0033] In a preferred embodiment, the processing temperature of the twin-screw extruder can be set as follows: the temperature of the first zone of the twin-screw extruder is 210°C, the temperature of the second zone is 210°C, the temperature of the third zone is 210°C, and t...

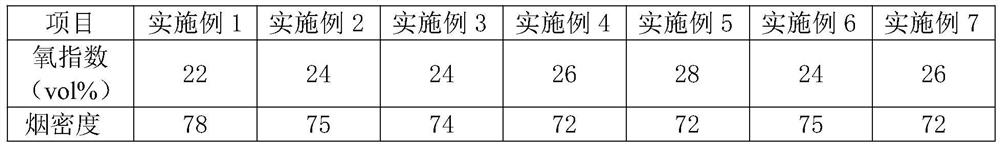

Embodiment 1

[0035] In terms of parts by weight, the flame-retardant extrusion grade PC / ABS composite material of this embodiment is composed of the following raw materials in parts by weight: 50 parts of PC, 30.8 parts of ABS, and 205H-g-MAH of toughening compatibilizer 3 parts, flame retardant BDP 10 parts, 4000 mesh kaolin 6 parts, anti-dripping agent 0.1 part.

[0036] The flame-retardant extrusion grade PC / ABS composite material of this embodiment is prepared according to the following method steps:

[0037] Step 1: Mix the above components in a medium speed mixer for 5 minutes;

[0038] Step 2: Then extrude and granulate the components mixed in step 1 through a twin-screw extruder with a melting temperature of 210-260°C.

[0039] In this step, the temperature of each section of the twin-screw extruder is set as follows: the temperature of the first zone of the twin-screw extruder is 210°C, the temperature of the second zone is 210°C, the temperature of the third zone is 210°C, the t...

Embodiment 2

[0041] In terms of parts by weight, the flame-retardant extrusion grade PC / ABS composite material of this embodiment is composed of the following raw materials in parts by weight: 55 parts of PC, 25.8 parts of ABS, and 205H-g-MAH of toughening compatibilizer 3 parts, flame retardant BDP 10 parts, 4000 mesh kaolin 6 parts, anti-dripping agent 0.2 parts.

[0042] The flame-retardant extrusion grade PC / ABS composite material of this embodiment is prepared according to the following method steps:

[0043] Step 1: Mix the above components in a medium speed mixer for 5 minutes;

[0044] Step 2: Then extrude and granulate the components mixed in step 1 through a twin-screw extruder with a melting temperature of 210-260°C.

[0045]In this step, the temperature of each section of the twin-screw extruder is set as follows: the temperature of the first zone of the twin-screw extruder is 210°C, the temperature of the second zone is 210°C, the temperature of the third zone is 210°C, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com