Nitrogen-doped magnetic porous carbon material as well as preparation method and application thereof

A technology of porous carbon materials and nitrogen doping, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problem of low dye adsorption performance, achieve fast adsorption rate and easy operation , the effect of super high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

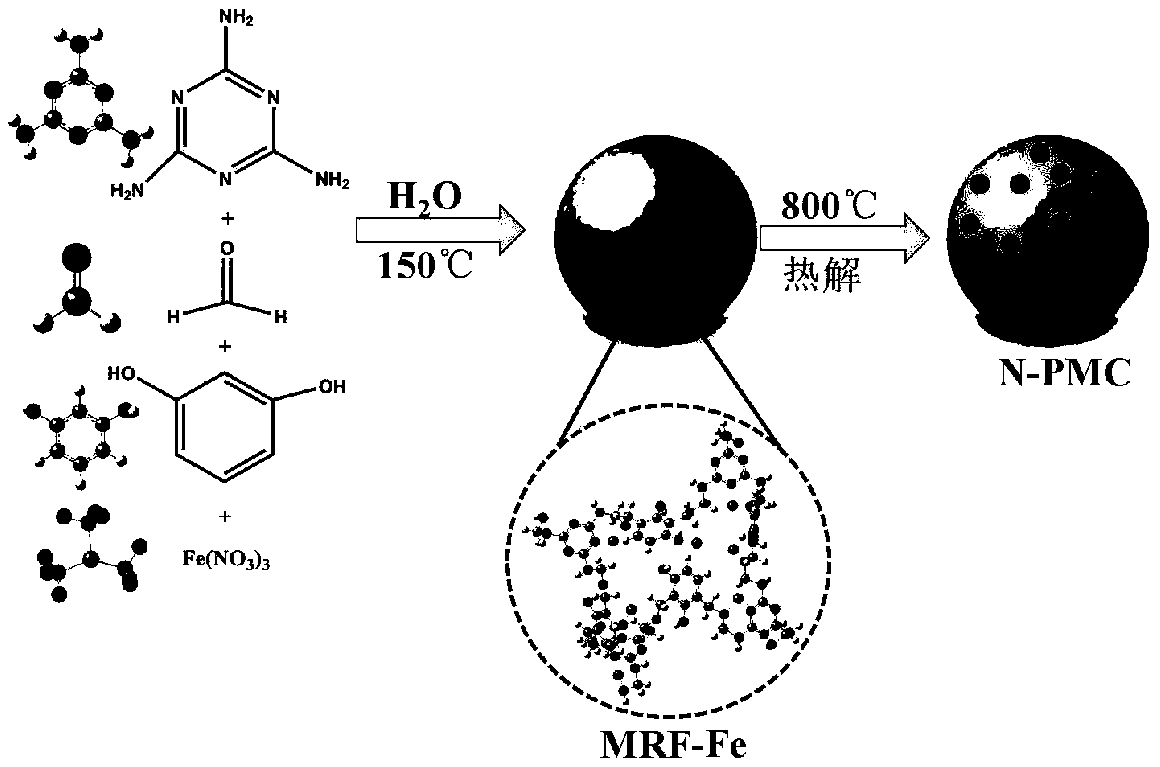

[0055] Embodiment 1: A kind of preparation method of nitrogen-doped magnetic porous carbon material

Embodiment 2

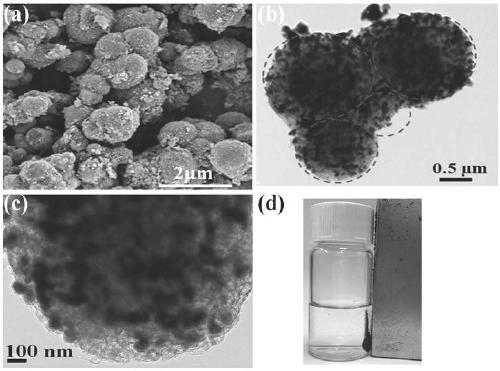

[0059] The porous magnetic carbon material N-PMC (2.5 mg) was added to MB aqueous solutions (5 mL) of different concentrations, and the shaking was continued for 24 hours at room temperature. The adsorbed N-PMC was separated from the solution under the action of an external magnet, and the filtrate concentration was characterized by UV-Vis spectroscopy at a wavelength of 664 nm. Adsorption capacity of N-PMC for MB and its removal rate. With the increase of the initial MB concentration, the adsorption capacity of MB by N-PMC gradually increased until it remained unchanged. At lower concentrations, more adsorption sites are available. After reaching the maximum adsorption capacity with increasing concentration, MB dye molecules occupy the available sites on the N-PMC surface. Therefore, after the concentration continues to increase, the adsorption amount tends to balance. Using the Langmuir isotherm model to fit the experimental data of the isotherm, it can be seen that the l...

Embodiment 3

[0061] N-PMC (2.5 mg) was added to MB aqueous solution (5 mL) with an initial concentration of 10 ppm and shaken for different times at regular intervals. The adsorbed solution was separated from the material under the action of an external magnet, and the concentration of the filtrate was measured by UV-Vis spectroscopy. The results showed that the removal rate of MB by N-PMC was as high as 99.99% within 1 minute. Furthermore, N-PMC was able to reduce MB solutions with a concentration of 10 ppm to almost zero within 1 minute. Further, fitting the experimental data with a pseudo-second-order kinetic model, the linear correlation coefficient is very high (R 2 >0.9999), the calculated adsorption rate constant k 2 The value is 1.34g·mg·min -1 , which is more than double that of other adsorbents adsorbed by MB. The above results fully demonstrate that N-PMC has an extremely fast adsorption rate for MB adsorption.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com