Plate welding method

A plate and laser welding technology, applied in welding equipment, laser welding equipment, arc welding equipment, etc., can solve the problems of poor welding process stability, violent evaporation of materials, splashing bottom, etc., to achieve smoothness, improve process stability, Effect of Surface Tension Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

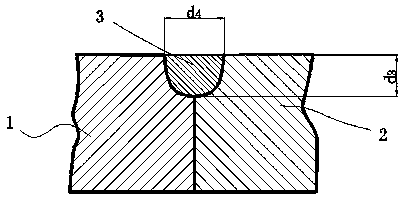

[0033] The following will be combined with the attached Figure 1-6 Specific embodiments of the present invention will be described in detail.

[0034] In this embodiment, a method for welding plates includes the following steps.

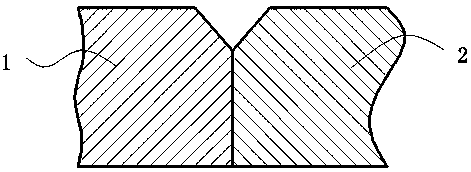

[0035] Step 1: Process the first base material 1 and the second base material 2 to form the butt end surface and the groove surface, and remove the impurities on the upper and lower surfaces of the first base material 1 and the second base material 2, the butt surface and the welding groove, these impurities Including water stains, oil stains, rust, etc.

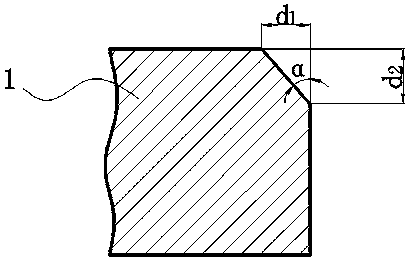

[0036] Such as figure 1 As shown, the first base metal 1 and the second base metal 2 have the same groove surface structure and size, and the groove width d 1 1mm~2mm, groove height d 2 1.5mm~3mm.

[0037] Step 2: Use a special welding fixture to accurately butt and clamp the first base metal 1 and the second base metal 2 to achieve precise alignment of the welding grooves of the first base m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com