Green roof partition type multilevel AO integrated wastewater treatment technology

A green-top partition type and sewage treatment technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, biological treatment devices, etc., can solve the problem of low adsorption capacity of fillers, prolong hydraulic retention time, improve Oxygen mass transfer efficiency and oxygen utilization rate, the effect of full anaerobic phosphorus release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

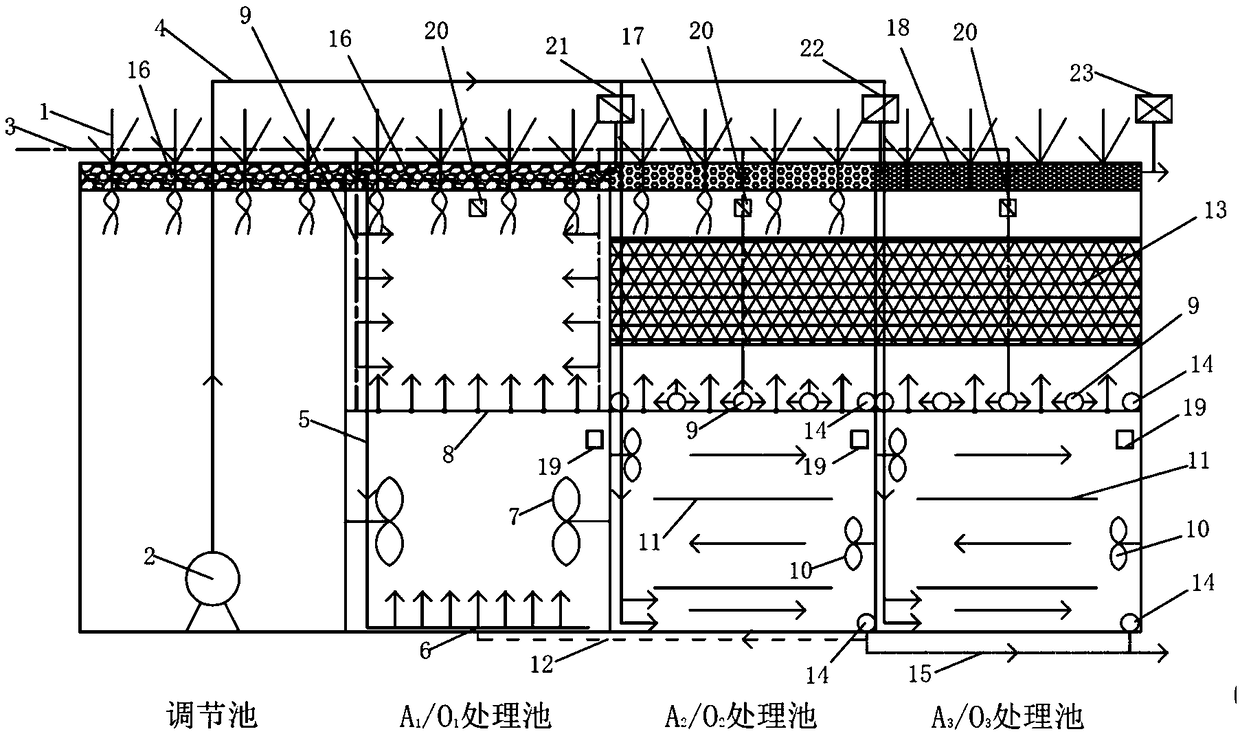

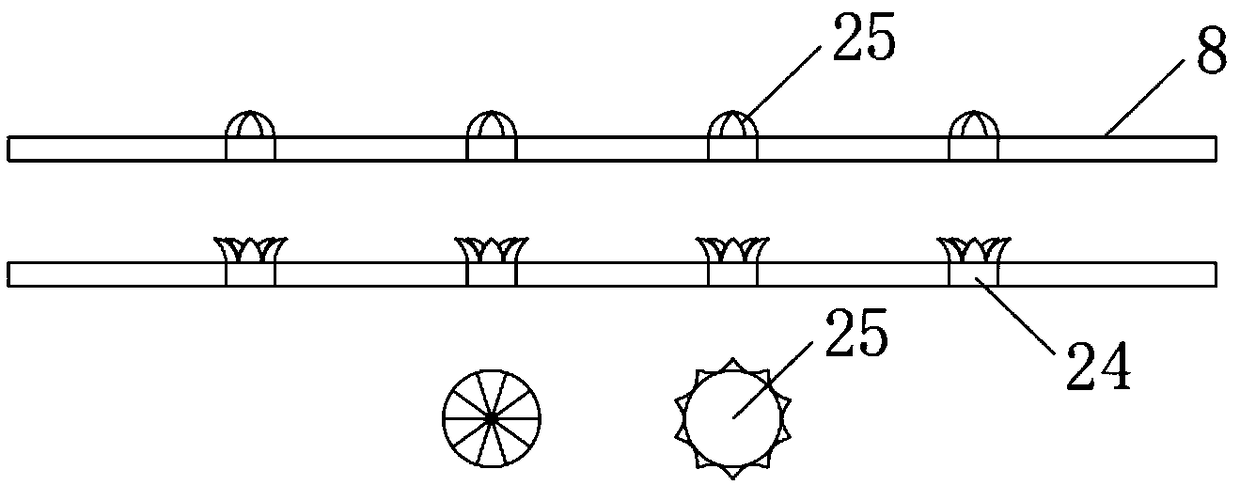

[0049] Example 1, see Figure 1 to Figure 3 :

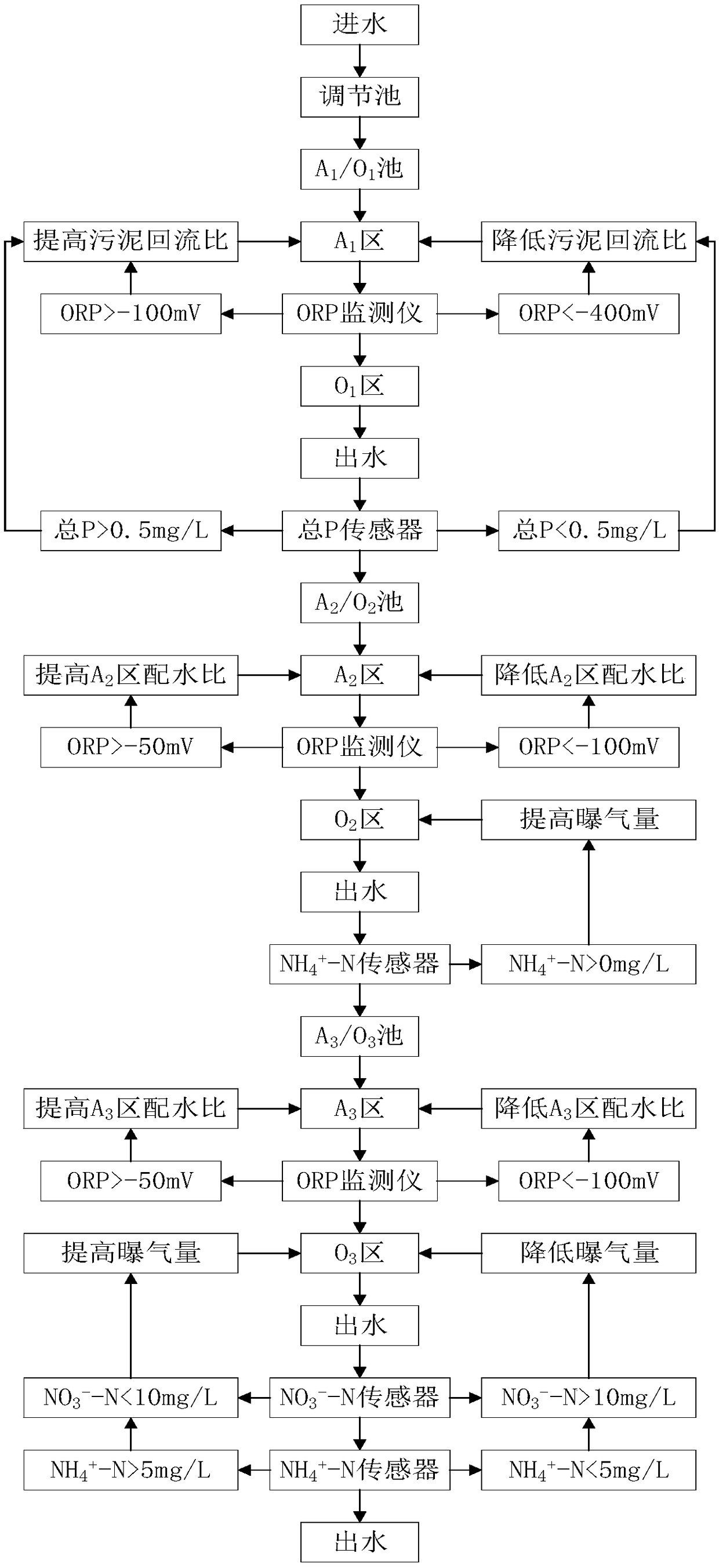

[0050] A kind of multi-level AO integrated sewage treatment process with green top partition type adopts a three-level A / O integrated treatment pool with constructed wetland on the top of the pool, including the following steps (see figure 1 ):

[0051] 1) Sewage enters the regulating tank for homogenization and equalization;

[0052] 2) The sewage in the regulating tank enters the first-level A through the overflow pipe 5 1 / O 1 A of processing pool 1 After anaerobic phosphorus release in the treatment tank, the O 1 In the treatment pool, aerobic phosphorus absorption and nitrification are carried out; part of the sewage in the adjustment pool is sent to the secondary A through the water distribution pipe 4 by the submersible pump 2 2 / O 2 A of processing pool 2 Treatment pool and tertiary A 3 / O 3 A of processing pool 3 Treatment ponds, which provide carbon sources for denitrification;

[0053] 3)O 1 The sewage tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com