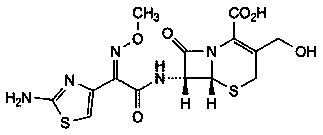

Preparation method of desacetylcefotaxime

A technology of acetyl cefotaxime and D-7-ACA, which is applied in the field of preparation of deacetyl cefotaxime, can solve the problems such as not found, and achieve the effect of improving production quality, simple and fast synthesis operation, and easy separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 15.14g of D-7-ACA, 150mL of dichloromethane, 30mL of isopropanol into a 250mL four-necked bottle, stir at a temperature of 5-10°C, add 20.10g of AE-active ester, continue stirring evenly, add 2g of sodium metabisulfite 15 mL of triethylamine was slowly added dropwise, and the dropwise addition was completed in about 20 minutes. The reaction was stirred for 3 hours, and the temperature was controlled at 5-10°C. Then wash the water phase once with 50 mL of dichloromethane; discard the dichloromethane, decolorize the water phase with an appropriate amount of activated carbon, filter, control the temperature at 0-5°C, add 60 mL of isopropanol to the filtrate, stir, and slowly add 10 % hydrochloric acid solution, adjust the pH of the system to 1.0-2.0, stir for 30 minutes, filter with suction, dry the filter cake under reduced pressure in an oven at 40°C for 4 hours, and weigh to obtain 18.45g of the product (yield 52.36%). The purity (HPLC) of the target product obtaine...

Embodiment 2

[0038] Add 15.02g of D-7-ACA, 150mL of dichloroethane, 30mL of isopropanol into a 250mL four-necked bottle, stir at a temperature of 0-5°C, add 20.08g of AE-active ester, continue stirring evenly, add 2g of heavy Sodium sulfite, slowly add 15mL of triethylamine dropwise, the dropwise addition is completed in about 20min, stir the reaction for 3h, under the condition of temperature control 10-15°C, extract the reaction solution with purified water 3 times, 40mL each time, separate the liquid, collect and combine the aqueous phase , and then wash the water phase once with 50mL dichloroethane; discard the dichloroethane, decolorize the water phase with an appropriate amount of activated carbon, filter, control the temperature at 0-5°C, add 60mL isopropanol to the filtrate, stir, and then slowly Add 10% hydrochloric acid solution dropwise, adjust the pH of the system to 2.0-3.0, stir for 30 minutes, filter with suction, dry the filter cake under reduced pressure in an oven at 40°C ...

Embodiment 3

[0040]Add 15.08g of D-7-ACA, 150mL of dichloromethane and 30mL of methanol into a 250mL four-necked bottle, stir at -5-0°C under temperature control, add 20.01g of AE-active ester, continue stirring evenly, add 2g of sodium metabisulfite, Slowly add 15 mL of triethylamine dropwise, and the dropwise addition is completed in about 20 minutes. Stir the reaction for 3 hours. Under the condition of temperature control at 10-15°C, extract the reaction solution with purified water 3 times, 40 mL each time, separate the liquids, collect and combine the aqueous phases, and then Wash the water phase once with 50 mL of dichloromethane; discard the dichloromethane, decolorize the water phase with an appropriate amount of activated carbon, filter, control the temperature at 0-5°C, add 60 mL of methanol to the filtrate, stir, and slowly add 10% hydrochloric acid solution dropwise , adjust the pH of the system to 3.0-4.0, stir for 30 minutes, filter with suction, dry the filter cake in an ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com