Polypropylene composite material with high strength and acid and alkali resistance and preparation method thereof

A technology of composite materials and polypropylene, which is applied in the field of high-strength, acid and alkali-resistant polypropylene composite materials and its preparation, and can solve the problems of large reduction in the strength of polypropylene materials and failure to meet the use requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

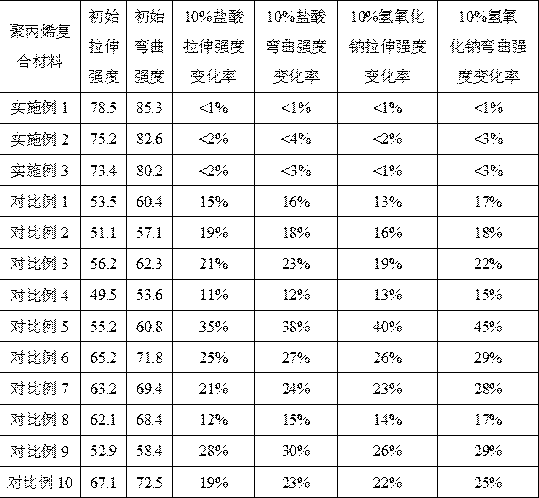

Examples

Embodiment 1

[0017] A high-strength, acid and alkali-resistant polypropylene composite material, made of the following raw materials in parts by weight: 100 parts of polypropylene, 15 parts of octa(N-cyclohexyl)benzamidopolysilsesquioxane, nucleated 0.3 part of anti-oxidant, 1 part of antioxidant, the melt index of described polypropylene measured by GB / T3682-2000 method is 17.5g / 10min; The described nucleating agent is two (p-methylbenzylidene) sorbitol, The mixture of TMB-5 and sodium 2,2'-methylenebis(4,6-di-tert-butylphenyl)phosphate, the mass ratio of the three is 100:20:3; the antioxidant is an antioxidant 1076.

[0018] The preparation method of above-mentioned polypropylene composite material, comprises the following steps:

[0019] (1) First, pre-mix polypropylene, octa(N-cyclohexyl)benzamidopolysilsesquioxane, nucleating agent, and antioxidant in a high-speed mixer according to the proportion;

[0020] (2) Add the pre-mixture obtained in step (1) into a twin-screw extruder for ...

Embodiment 2

[0023] A high-strength, acid and alkali-resistant polypropylene composite material, made of the following raw materials in parts by weight: 100 parts of polypropylene, 13 parts of octa(N-cyclohexyl)benzamide polysilsesquioxane, nucleated 0.5 part of agent, 2 parts of antioxidant, the melting index of described polypropylene is 19.6g / 10min measured by GB / T3682-2000 method; The described nucleating agent is two (p-ethylbenzylidene) sorbitol, A mixture of TMB-5 and 2,2'-methylenebis(4,6-di-tert-butylphenyl)aluminum phosphate, the mass ratio of the three is 100:10:5; the antioxidant is an antioxidant 1010.

[0024] The preparation method of the above-mentioned polypropylene composite material is the same as in Example 1.

Embodiment 3

[0026] A high-strength, acid and alkali-resistant polypropylene composite material, made of the following raw materials in parts by weight: 100 parts of polypropylene, 10 parts of octa(N-cyclohexyl)benzamidopolysilsesquioxane, nucleated 0.1 part of anti-oxidant, 0.5 part of antioxidant; The melting index of the polypropylene measured by GB / T3682-2000 method is 15.1g / 10min; The nucleating agent is two (p-methylbenzylidene) sorbitol, A mixture of TMB-5 and 2,2'-methylenebis(4,6-di-tert-butylphenyl)aluminum phosphate, the mass ratio of the three is 100:30:4; the antioxidant is an antioxidant One or more of 1076, antioxidant 1024, antioxidant 1010 and antioxidant 168.

[0027] The preparation method of the above-mentioned polypropylene composite material is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com