Environment-friendly chloroprene adhesive and preparation method thereof

A neoprene and environment-friendly technology, applied in the field of chemical materials, can solve the problems of inability to construct for a long time, irritating odor, etc., and achieve the effects of convenient source, low price and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

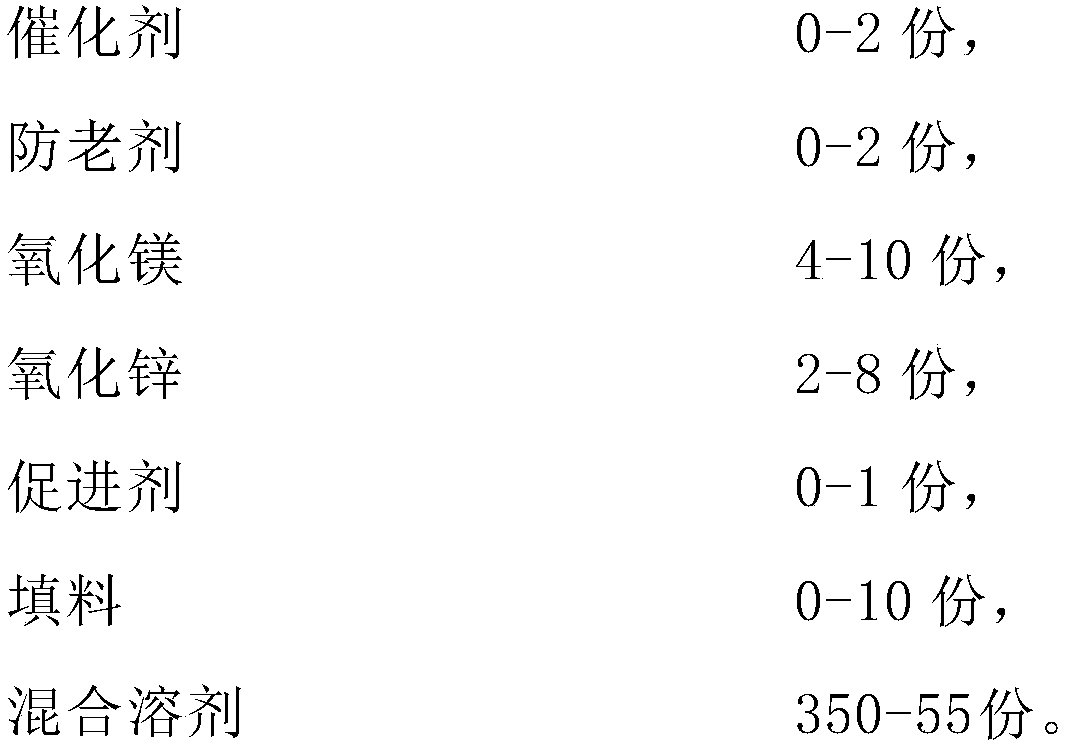

[0033] Raw material formula:

[0034]

[0035]

[0036] Preparation:

[0037] The solid materials other than resin 2402 and fumed silica are internally kneaded at a temperature not exceeding 100°C with an internal mixer, and then passed through an open mixer. Shredding and crushing integrated machine into small pieces or flakes;

[0038] Take part of methylcyclohexane: 80 parts of mixed solvent of cyclohexane = 1:1, add 6 parts of light activated magnesium oxide, stir for a while, wait for the light activated magnesium oxide to be completely dispersed, add 60 parts of resin, and carry out pre-reaction solution Preparation, add the catalyst after 1h-2h, and stop stirring when the reaction liquid is khaki-yellow and viscous, and there is no white precipitate. It is best to stir and react for 6h-8h, and it needs to stand for later use.

[0039] Add the remaining solvent into the reactor, add the above-mentioned pre-reaction solution, stir and add the pulverized and shredd...

Embodiment 2

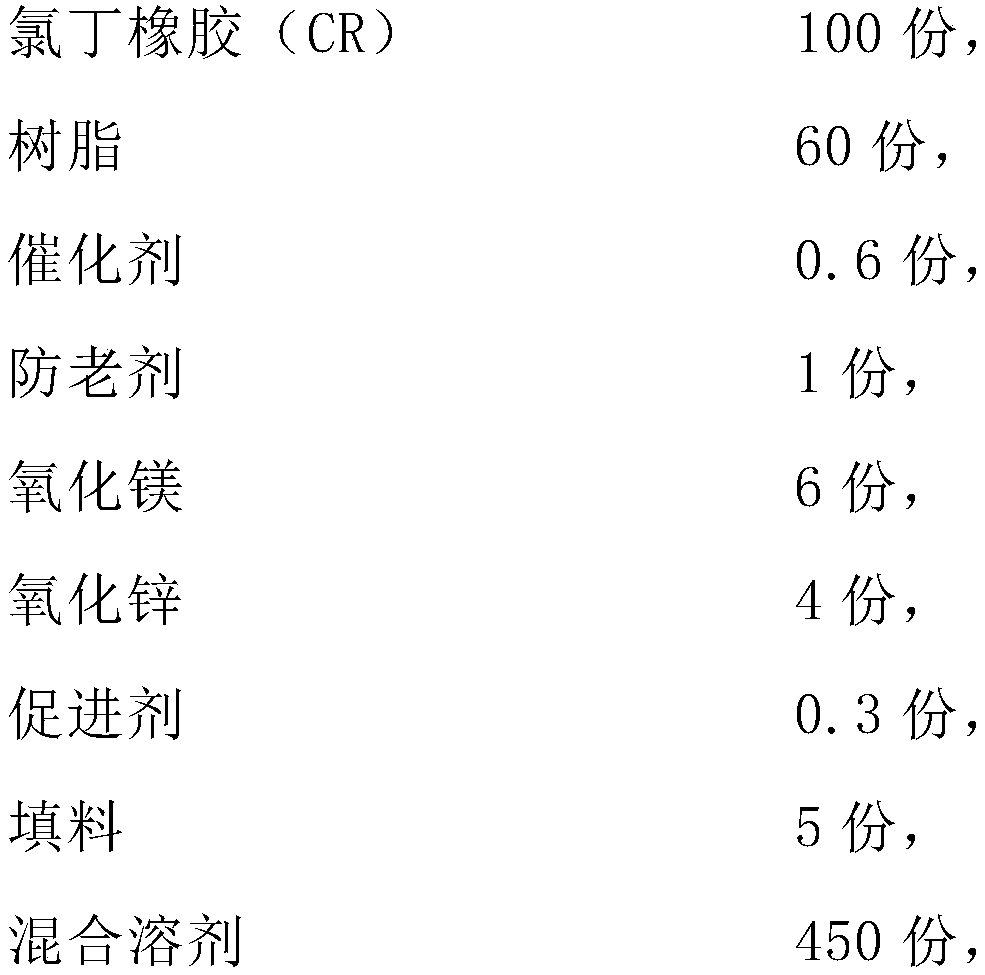

[0044] Raw material formula:

[0045]

[0046]

[0047] Preparation:

[0048] The solid materials other than TAMANOL 526 and fumed silica are internally mixed at a temperature not exceeding 100°C with an internal mixer, and then passed through an open mixer. Shredding and crushing integrated machine into small pieces or flakes;

[0049] Take part of methylcyclohexane: 106.6 parts of mixed solvent of cyclohexane = 1:1, add 8 parts of light activated magnesia, stir for a while, wait for the light activated magnesia to be completely dispersed, add 80 parts of resin, and carry out pre-reaction solution Preparation, add the catalyst after 1h-2h, and stop stirring when the reaction liquid is khaki-yellow and viscous, and there is no white precipitate. It is best to stir and react for 6h-8h, and it needs to stand for later use.

[0050] Add the remaining solvent into the reactor, add the above-mentioned pre-reaction solution, stir and add the pulverized and shredded rubber, s...

Embodiment 3

[0055] Raw material formula:

[0056]

[0057] Preparation:

[0058] The solid materials except TAMANOL 526 and resin 2402 are internally kneaded at a temperature not exceeding 100°C with an internal mixer, and then passed through an open mixer. Crushing machine into small pieces or flakes;

[0059] Take part of methylcyclohexane: 106.6 parts of mixed solvent of cyclohexane = 1:1, add 8 parts of light activated magnesia, stir for a while, wait for the light activated magnesia to be completely dispersed, add 80 parts of resin, and carry out pre-reaction solution Preparation, add the catalyst after 1h-2h, and stop stirring when the reaction liquid is khaki-yellow and viscous, and there is no white precipitate. It is best to stir and react for 6h-8h, and it needs to stand for later use.

[0060] Add the remaining solvent into the reactor, add the above-mentioned pre-reaction solution, stir and add the pulverized and shredded rubber, stir and dissolve evenly, then add gas-phase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com