Frame components based on laser selective melting forming technology

A laser selective melting and forming technology, which is applied to the frame of the engine, pipe components, supporting machines, etc., can solve problems affecting the reliability of the frame structure, improve reliability and anti-vibration performance, and reduce the number of pipelines Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

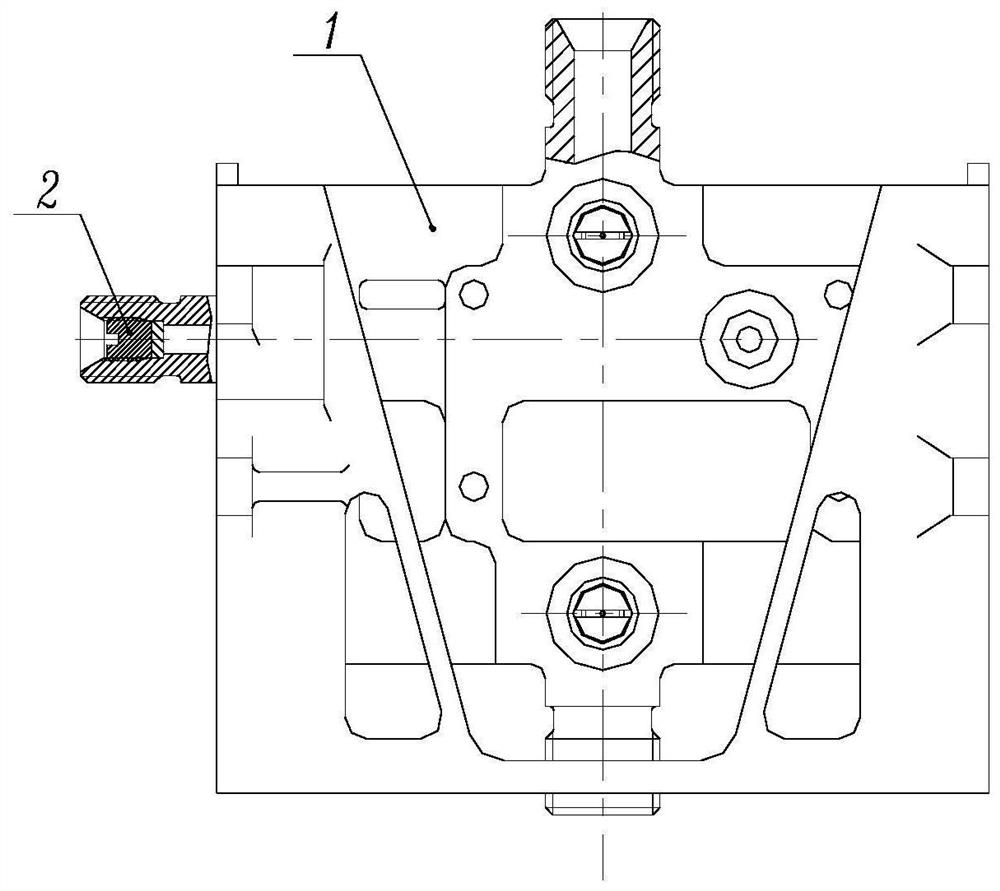

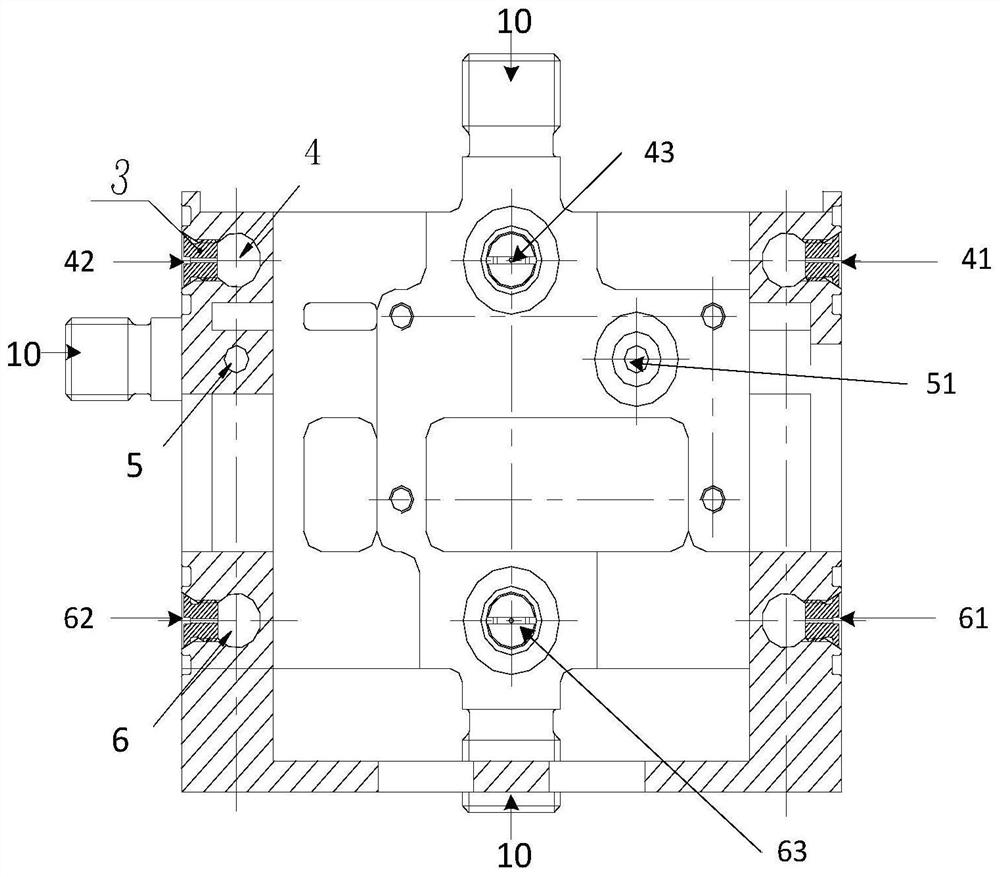

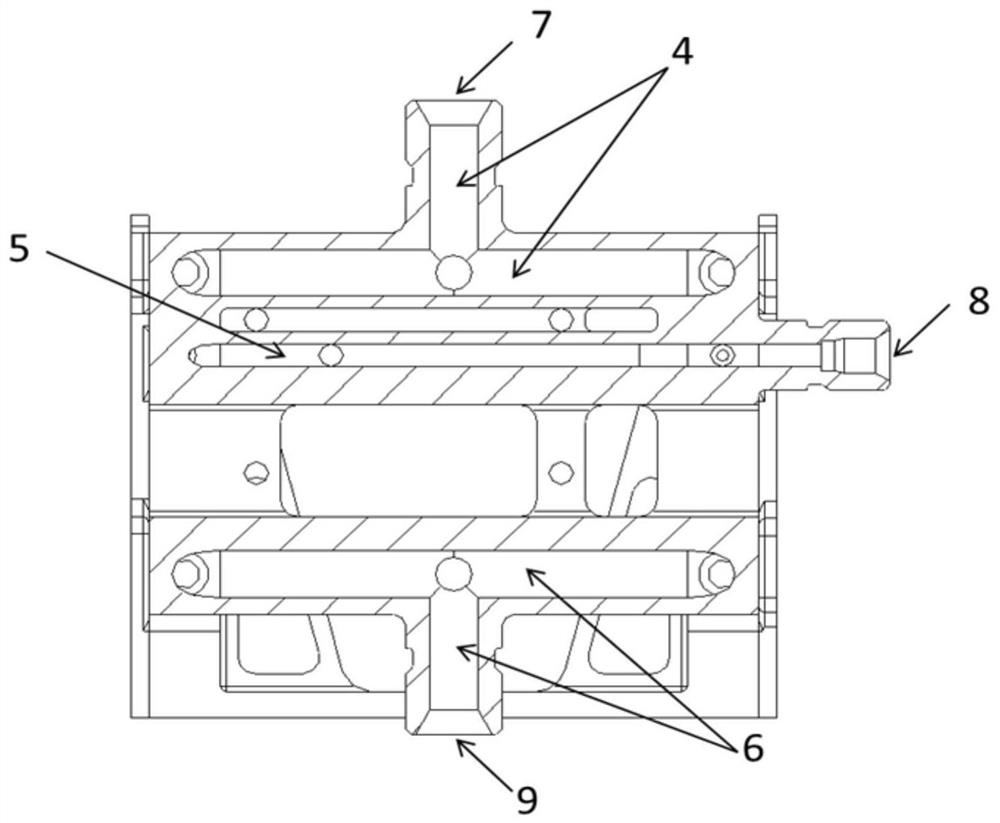

[0065] Such as figure 1 and figure 2 As shown in the figure, it is a structural schematic diagram of the laser selective melting forming frame assembly for the attitude control power system of a certain type of missile weapon. The channel distributor is composed of frame 1, filter device 2, throttle orifice 3 and other parts, and can provide three kinds of working media for each single engine at the same time.

[0066] When designing the frame structure, according to the layout scheme of the single engine, determine the specific structural form of the frame, the mechanical interface connected with the engine and the outer contour size. Compared with traditional mechanical processing methods, laser selective melting forming technology has excellent technical advantages in forming complex structures, and can design the frame structure for maximum weight reduction without increasing processing difficulty. Generally, only 90° right-angle transition connection can be selected fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com