High-precision full-automatic preparation process technology of industrial microgram-grade strong base

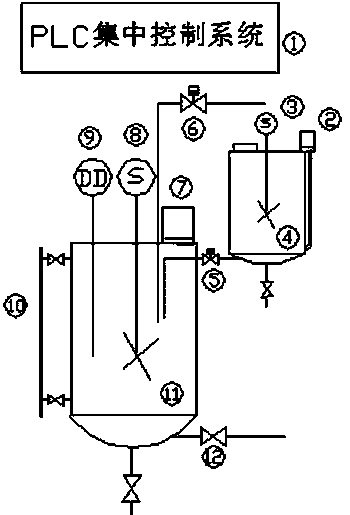

A process technology and high-precision technology, which is applied in the direction of agitator accessories, drive agitator dissolution, mixer, etc., and can solve problems such as steam turbine salt accumulation accidents, abnormal water vapor indicators, and steam turbine salt accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] A single-unit 300MW coal-fired generator set in Yunnan belongs to a subcritical pressure steam drum furnace. Before the implementation of the present invention, manual dispensing will be carried out once a month, and the dispensing concentration will only be based on the amount of solid sodium hydroxide manually input and the liquid level of the dispensing box (manually operated) Filling valve) roughly estimates that the dosing concentration is relatively extensive and unstable, and impact dosing often occurs (insufficient or overdosing of dosing can easily cause acid or caustic corrosion problems in the thermal system, causing serious safety hazards to power plants). It also causes personal frequent contact with strong alkali hazardous chemicals, and it will cause a lot of labor cost waste over the years. After the implementation of the present invention, the concentration of the dosing liquid is stable, and the pH value of the furnace water is stably controlled to be b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com