Device and method for cutting crystalline silicon wafer by pulse laser

A technology for cutting crystals and pulsed lasers, which can be used in laser welding equipment, semiconductor devices, electrical components, etc., and can solve problems such as loss of photoelectric conversion efficiency and difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

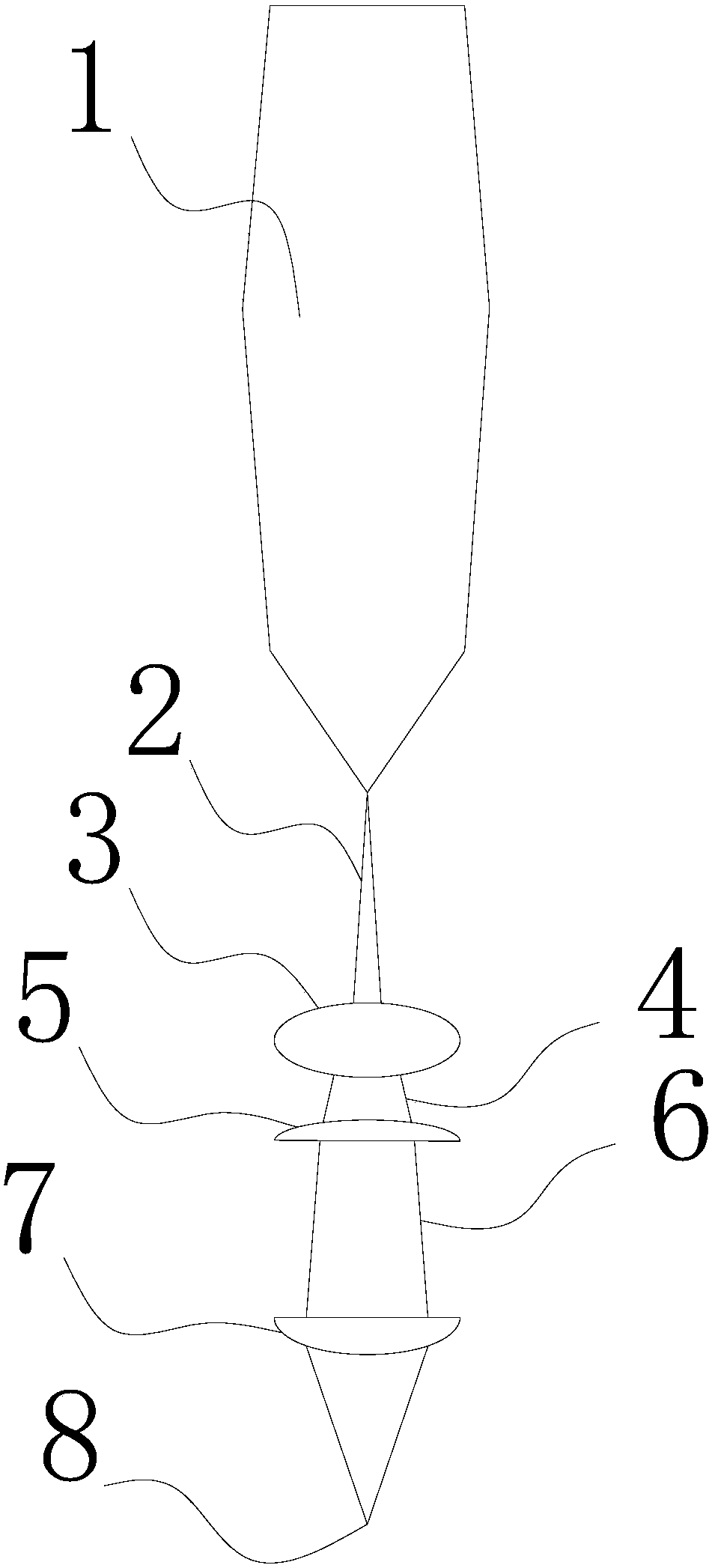

[0018] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0019] A method for pulsed laser cutting of crystalline silicon wafers includes the following steps:

[0020] The step of generating a pulsed laser beam, the pulsed laser spot formed by the pulsed laser beam has two mutually perpendicular axes with different lengths;

[0021] And the step of using the pulsed laser beam to cut the crystalline silicon wafer.

[0022] In the prior art, in the technical field of pulsed laser cutting, efforts are generally made to reduce the converging size (beam size) and pulse laser density of pulsed lasers. The cross-section of pulsed laser beams is circular, and it is used in most materials. In cutting, it is sufficient to meet the above two conditions, so no one thinks about the direction of improvement from other angles (because those skilled in the art have deemed it unnecessary or impossible), but the current technology,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com