Pollution-free preparation method of periodic mesoporous organic silicon oxide material

An organic silicon oxide, periodic technology, applied in the field of mesoporous materials, can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

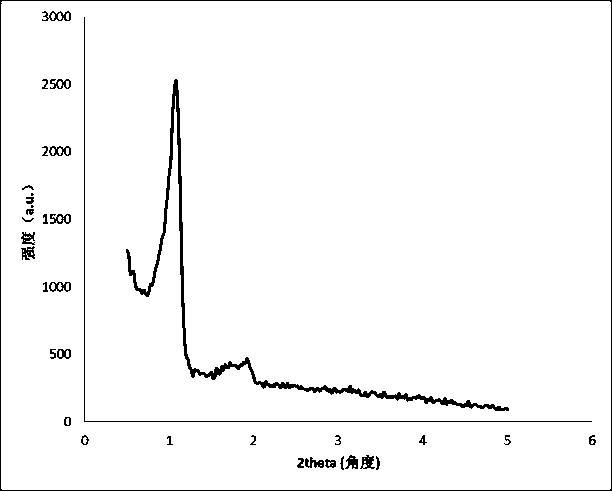

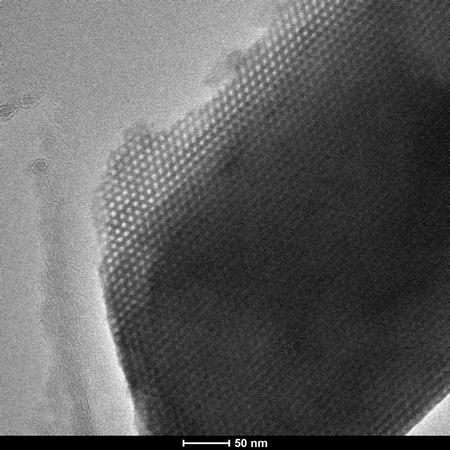

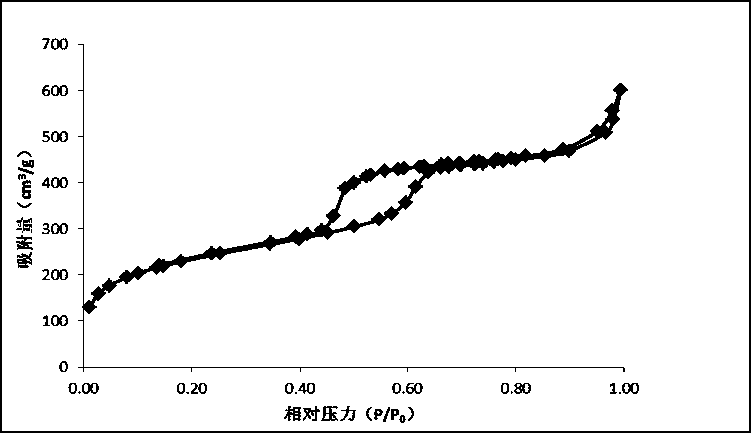

Image

Examples

Embodiment 1

[0032] A green preparation method of a periodic mesoporous organic silicon oxide material, comprising the following steps:

[0033] (1) Add 0.107g Na 2 S 2 o 8 Dissolve in 10ml of water, add 2ml of 1,2-bis(triethoxysilyl)ethane while stirring, and then ultrasonicate the mixture at 35°C for 1 hour under 100W ultrasonic power until the solution is uniform without stratification to obtain a solution a.

[0034] (2) Mix 1.04g of P123 solution in 26ml of water, stir for 6 hours until completely dissolved, then add 0.5g of NaCl, continue stirring until completely dissolved to obtain solution B.

[0035] (3) Add solution B to solution A, stir the solution evenly, and ultrasonicate the solution at 40 degrees Celsius for 0.5 hours under 100W ultrasonic power to obtain a milky white sol, then continue to stir it at 40 degrees Celsius for 12 hours, and transfer it to the belt polymer In a reaction kettle lined with tetrafluoroethylene, crystallize at 100 degrees Celsius for 48 hours....

Embodiment 2

[0039] A green preparation method of a periodic mesoporous organic silicon oxide material, comprising the following steps:

[0040] (1) Add 0.053g Na 2 S 2 o 8 Dissolve in 10ml of water, add 2ml of 1,2-bis(trimethoxysilyl)ethane while stirring, and then ultrasonicate the mixture at 35°C for 1 hour under 50W ultrasonic power until the solution is uniform without stratification to obtain solution A .

[0041] (2) Mix 1.21g of P123 solution in 26ml of water, stir for 6 hours until completely dissolved, then add 0.1g of KCl, continue stirring until completely dissolved to obtain solution B.

[0042] (3) Add solution B to solution A, stir the solution evenly, and ultrasonicate the solution at 40 degrees Celsius for 0.5 hours under 50W ultrasonic power to obtain a milky white sol, then continue to stir it at 40 degrees Celsius for 24 hours, and then transfer it to the belt polymer In a reaction kettle lined with tetrafluoroethylene, it was crystallized at 100 degrees Celsius for...

Embodiment 3

[0046] A green preparation method of a periodic mesoporous organic silicon oxide material, comprising the following steps:

[0047] (1) 1.325g Na 2 S 2 o 8 Dissolve in 10ml of water, add 4ml of 1,4-bis(triethoxysilyl)benzene under stirring, then ultrasonicate the mixture at 35°C for 30 minutes under 150W ultrasonic power until the solution is uniform without stratification to obtain solution A .

[0048] (2) Mix 1.92g of P123 solution in 52ml of water, stir for 6 hours until completely dissolved, then add 1.8g of NaCl, continue stirring until completely dissolved to obtain solution B.

[0049] (3) Add solution B to solution A, stir the solution evenly, and ultrasonicate the solution at 40 degrees Celsius for 30 minutes under 150W ultrasonic power to obtain a milky white sol, then continue to stir it at 40 degrees Celsius for 24 hours, and then transfer it to the belt polymer In a reaction kettle lined with tetrafluoroethylene, it was crystallized at 100 degrees Celsius for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com