Production process of low-ammonia wet sodium bicarbonate

A production process and wet weight technology, applied in the directions of alkali metal compounds, alkali metal carbonates, carbonate preparations, etc., can solve the problems of large loss of ammonia gas, increased ammonia consumption in production, poor air quality, etc. Production ammonia consumption, large equipment investment and operating power consumption, and the effect of low content of volatile ammonia components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

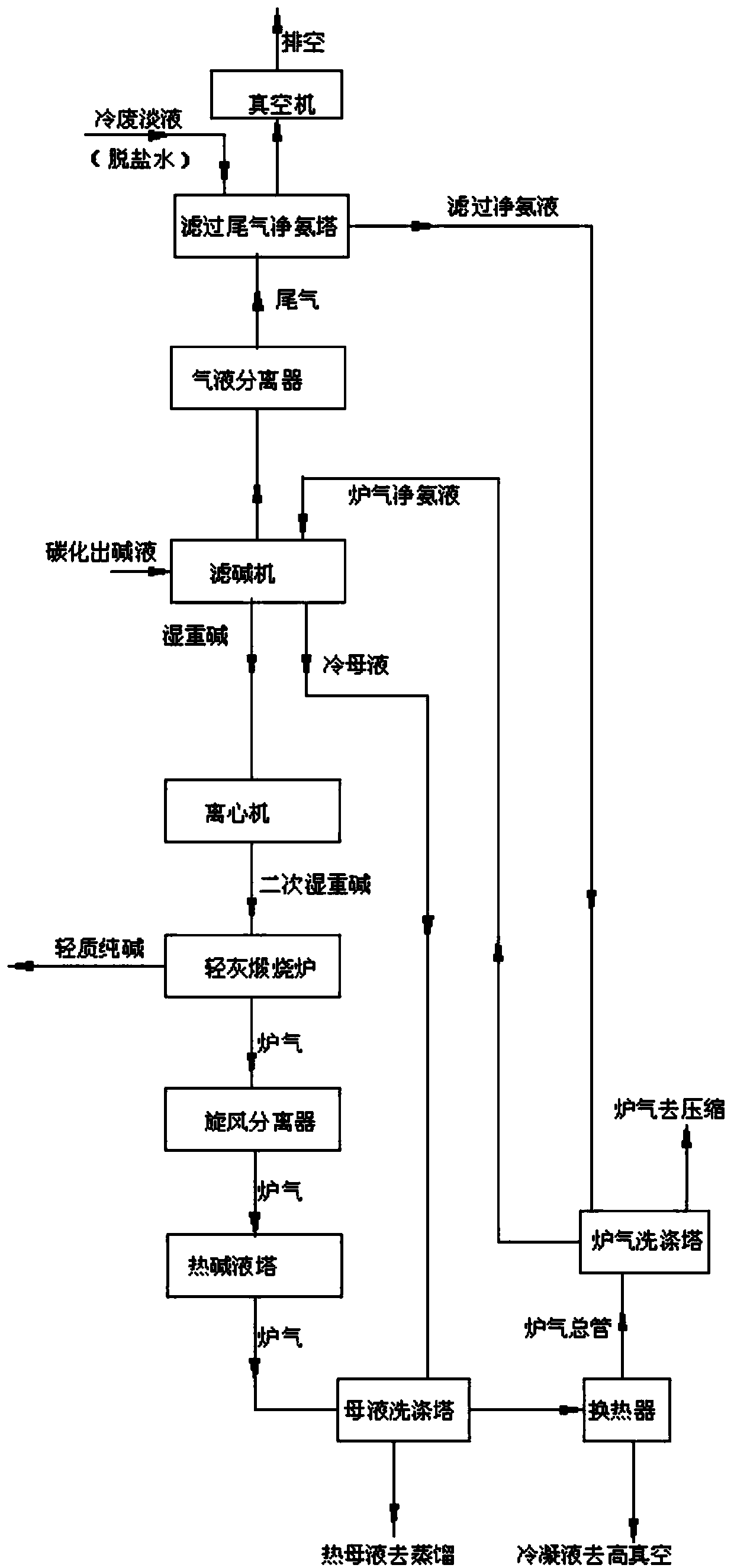

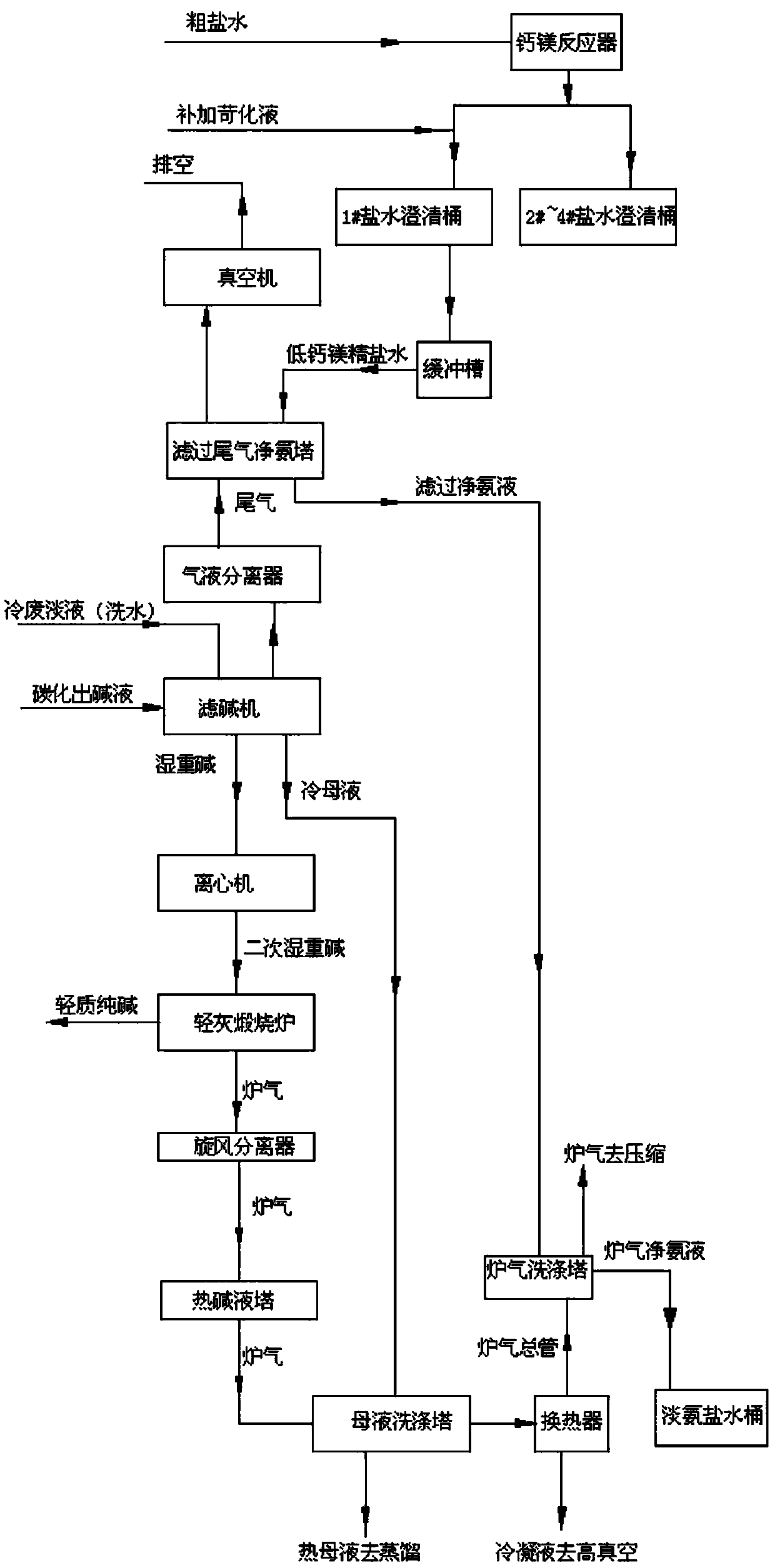

[0015] Describe the present invention below in conjunction with accompanying drawing and embodiment:

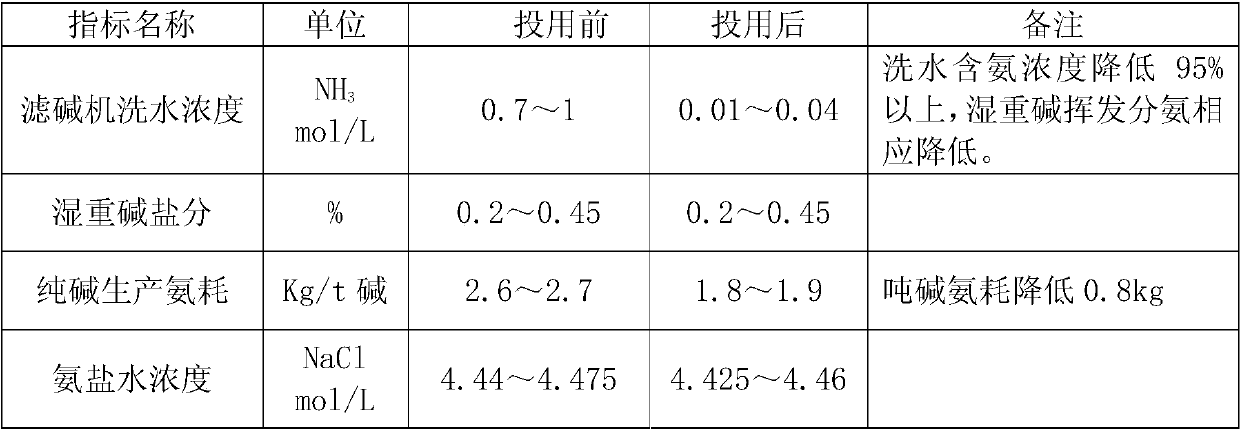

[0016] A low-ammonia wet heavy alkali production process, this embodiment relates to the two-step ammonia purification and water washing process of heavy alkali filtration and light ash furnace gas recovery in production systems such as soda ash and baking soda; specifically, a volatile ammonia component is provided Wet heavy alkali production method with low content.

[0017] Included in the production process of the heavy alkali filtration and calcination process of the soda ash system, the two media of low-calcium magnesium refined brine and cold waste liquid or desalinated water containing less than 1ti (ie: 0.05mol) of ammonia are used to operate independently. The specific steps are as follows:

[0018] 1. Brine refining process In the preparation process, the crude brine is sent to the calcium-magnesium reactor, and after the reaction in the calcium-magnesium reactor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com