Graded purification treatment technology for mixed wastewater

A technology for purification and mixed wastewater, applied in the direction of water/sewage multi-stage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the difficulty of biofilm formation, affect the activity of aerobic bacteria, reduce biological treatment efficiency and sewage Purification degree and other issues, to achieve good ventilation and ventilation effects, improve the degree of sewage purification, and improve the effect of aerobic bacteria activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A mixed wastewater classification purification treatment process, comprising the following steps:

[0044] Step 1. Preliminary filtration of the grid, preliminary filtration of some coarse debris in the wastewater;

[0045] Step 2, grit chamber treatment, the sand in the sewage is separated by sedimentation in the grit chamber;

[0046] Step 3, the initial sedimentation tank treatment, on the basis of the grit chamber treatment, the sand in the sewage is further settled and separated;

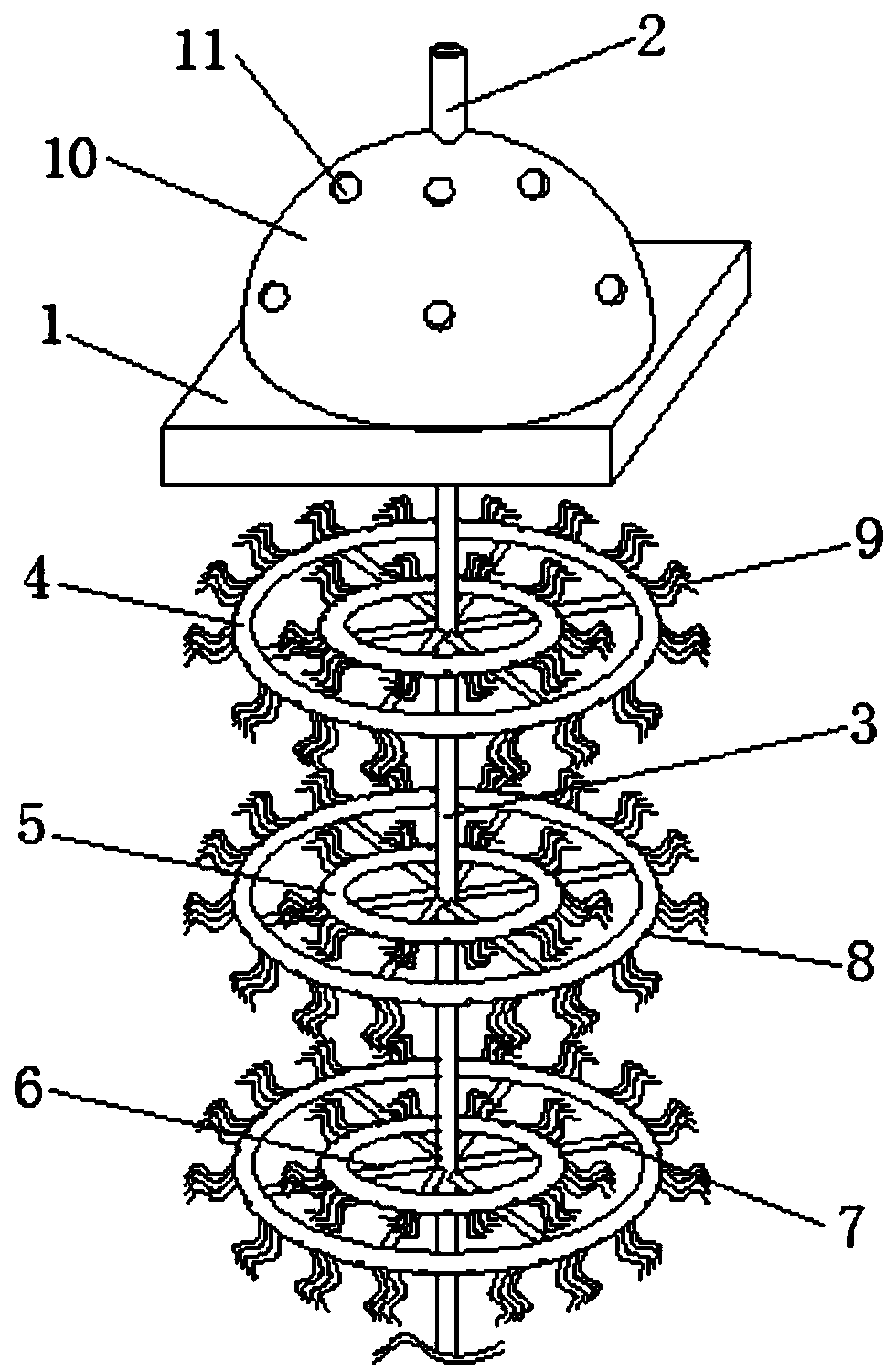

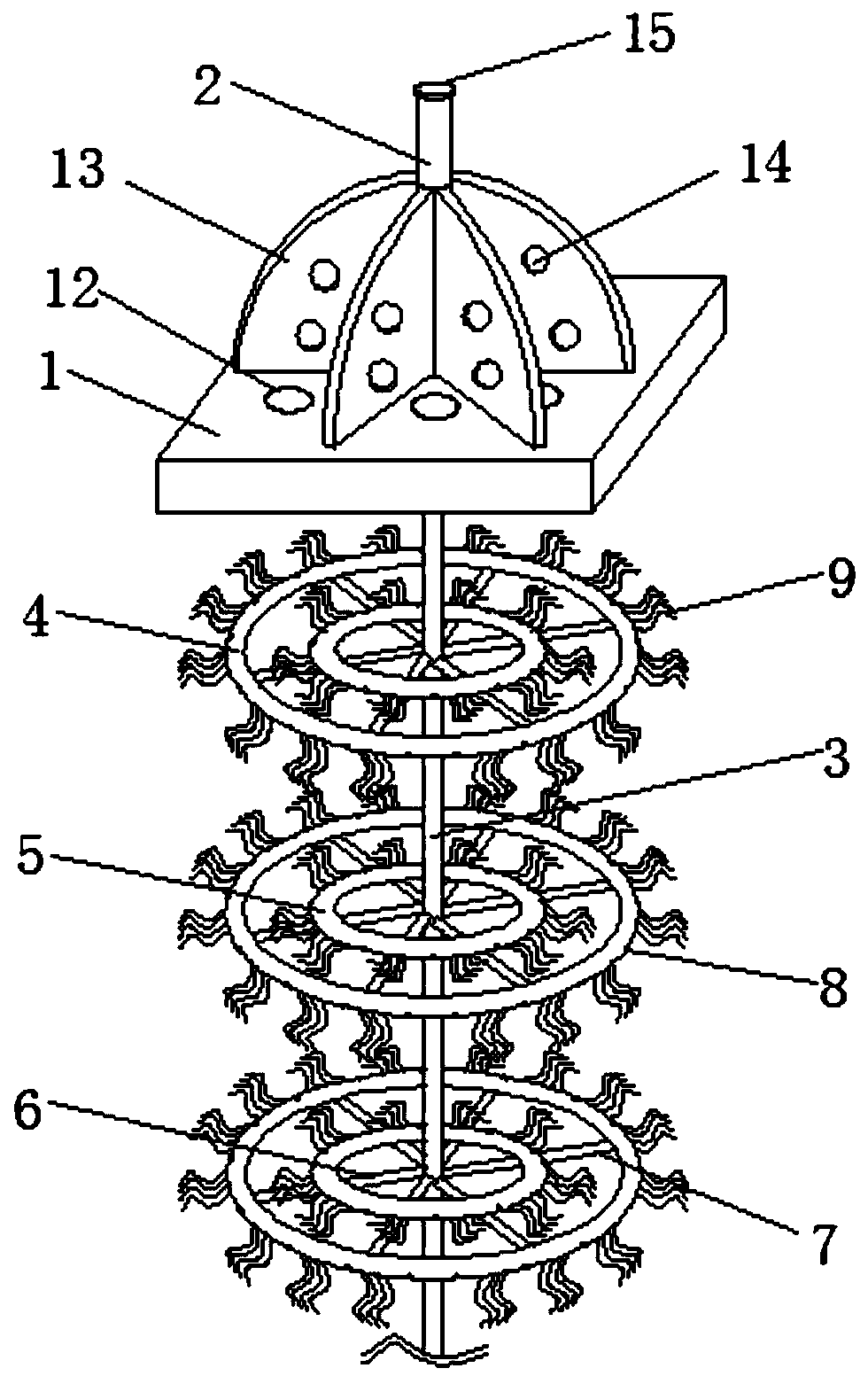

[0047] Step 4, biological treatment, adopting biological contact oxidation method to carry out sewage treatment;

[0048] Step 5, the second sedimentation, the sewage treated by the biological contact oxidation method is subjected to sedimentation and separation again;

[0049] Step 6, coagulation and precipitation, add coagulant and coagulant to the sewage after the second precipitation, the coagulant is PAC coagulant, the coagulant is polyacrylamide, activated silicic acid, bone glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com