Technology for preparing heavy alkyl benzene through dehydrogenation of heavy liquid wax and alkylation of heavy olefin

A technology for heavy alkyl benzene and heavy alkane, which is applied in the field of heavy liquid wax dehydrogenation to obtain heavy olefin and then alkylation to produce heavy alkyl benzene, can solve the problem of unstable composition, difficult to control carbon number, and influence on heavy alkane. The separation and purification of base benzene can improve the processing capacity, the interface activity is good, and the demand for high-quality heavy alkyl benzene can be solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

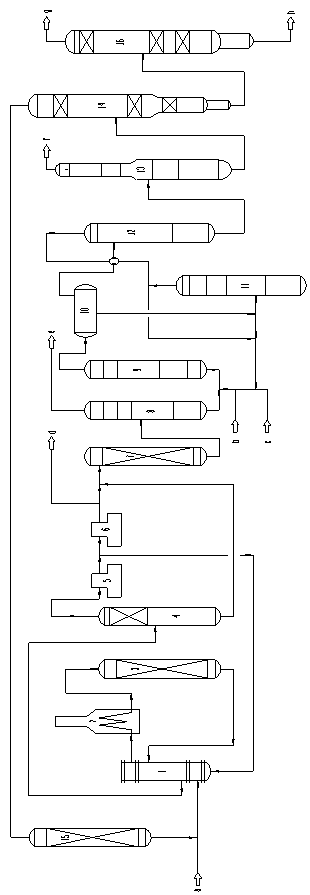

Image

Examples

Embodiment Construction

[0029] The present invention can be embodied from the application examples described below.

[0030] Contains C 16 ~C 19 The heavy liquid wax of normal alkanes, mixed with the circulating alkanes treated by the alumina defluorination processor 15, enters the combined feed heat exchanger 1, mixes with the circulating hydrogen, and exchanges heat with the dehydrogenation reaction product to 428.5°C before entering the feedstock The material heating furnace 2 is heated to the temperature required for the dehydrogenation reaction of 499°C, and enters the dehydrogenation reactor 3. Under the action of the dehydrogenation catalyst, the normal paraffin part undergoes dehydrogenation reaction to generate normal olefins and hydrogen, and the temperature of the reaction effluent is 460°C , reaction pressure 140kPa(g), reaction hydrogen to hydrocarbon ratio (mol) 6:1, LHSV 20~23 h -1 , the reaction catalyst is DF-2; the dehydrogenation reaction product goes to the combined feed heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com