Carboxyethyl chitosan/polyvinyl alcohol self-healing hydrogel as well as preparation method and application thereof

A technology of carboxyethyl chitosan and polyvinyl alcohol, which is applied in the field of biomedical materials, can solve the problems of brittleness and easy breakage of chitosan-based hydrogels, and achieves improved hydrophilicity, enhanced mechanical strength, good The effect of swelling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

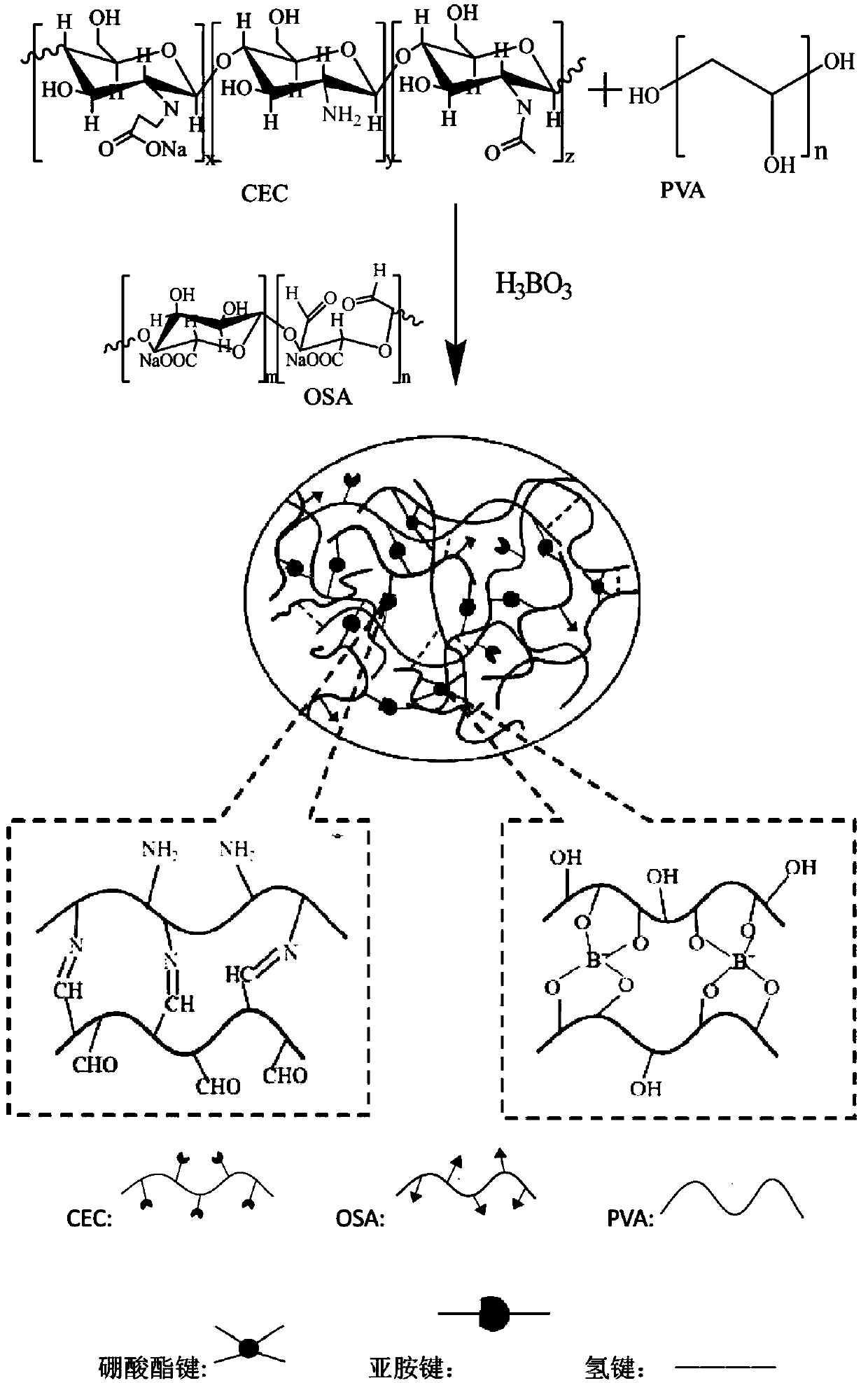

[0025] Such as figure 1 Shown, a kind of preparation method of carboxyethyl chitosan / polyvinyl alcohol self-healing hydrogel, concrete process is as follows:

[0026] (1) Dissolve 1.0g of polyvinyl alcohol in 30mL of water at 90°C, keep the temperature of the solution at 90°C, then add 1.0g of carboxyethyl chitosan to it, and continue stirring to completely dissolve the solid to obtain carboxyethyl chitosan Polysaccharide / polyvinyl alcohol complex solution. Wherein, the total concentration of carboxyethyl chitosan and polyvinyl alcohol is 67g / L.

[0027] (2) Dissolve accurately measured oxidized sodium alginate and boric acid in 10 mL of water to prepare a mixed crosslinking agent solution, wherein the concentration of oxidized sodium alginate is 100.0 g / L, and the concentration of boric acid is 2.0 g / L.

[0028] (3) Add 200 μL of mixed crosslinking agent solution to 5 mL of carboxyethyl chitosan / polyvinyl alcohol composite solution, stir quickly and evenly, and raise the te...

Embodiment 2

[0030] (1) Dissolve 1.0g of polyvinyl alcohol in 30mL of water at 90°C, keep the temperature of the solution at 90°C, then add 1.0g of carboxyethyl chitosan to it, and continue stirring to completely dissolve the solid to obtain carboxyethyl chitosan Polysaccharide / polyvinyl alcohol complex solution. Wherein, the total concentration of carboxyethyl chitosan and polyvinyl alcohol is 67g / L.

[0031] (2) Dissolve oxidized sodium alginate and boric acid in 10 mL of water to prepare a mixed crosslinking agent solution, wherein the concentration of oxidized sodium alginate is 100.0 g / L, and the concentration of boric acid is 2.0 g / L.

[0032] (3) Add 500 μL of mixed cross-linking agent solution to 5 mL of carboxyethyl chitosan / polyvinyl alcohol composite solution, stir quickly and evenly, and raise the temperature of the reaction solution to 30 ° C for 24 hours at a constant temperature to obtain carboxyethyl chitosan / Polyvinyl alcohol self-healing hydrogel.

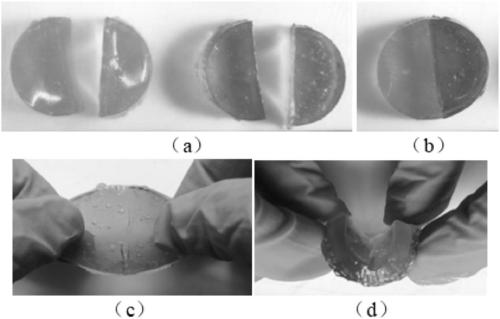

[0033] According t...

Embodiment 3

[0040] (1) Dissolve 1.0g of polyvinyl alcohol in 30mL of water at 90°C, keep the temperature of the solution at 90°C, then add 1.0g of carboxyethyl chitosan to it, and continue stirring to completely dissolve the solid to obtain carboxyethyl chitosan Polysaccharide / polyvinyl alcohol complex solution. Wherein, the total concentration of carboxyethyl chitosan and polyvinyl alcohol is 67g / L.

[0041] (2) Dissolve oxidized sodium alginate and boric acid in 10 mL of water to prepare a mixed crosslinking agent solution, wherein the concentration of oxidized sodium alginate is 100.0 g / L, and the concentration of boric acid is 2.0 g / L.

[0042] (3) Add 100 μL of mixed cross-linking agent solution to 5 mL of carboxyethyl chitosan / polyvinyl alcohol composite solution, stir quickly and evenly, raise the temperature of the reaction solution to 30° C. and react at a constant temperature for 24 hours to obtain carboxyethyl chitosan / Polyvinyl alcohol self-healing hydrogel.

[0043] An eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

| Degree of swelling | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com