Processing method of nutritional black vinegar

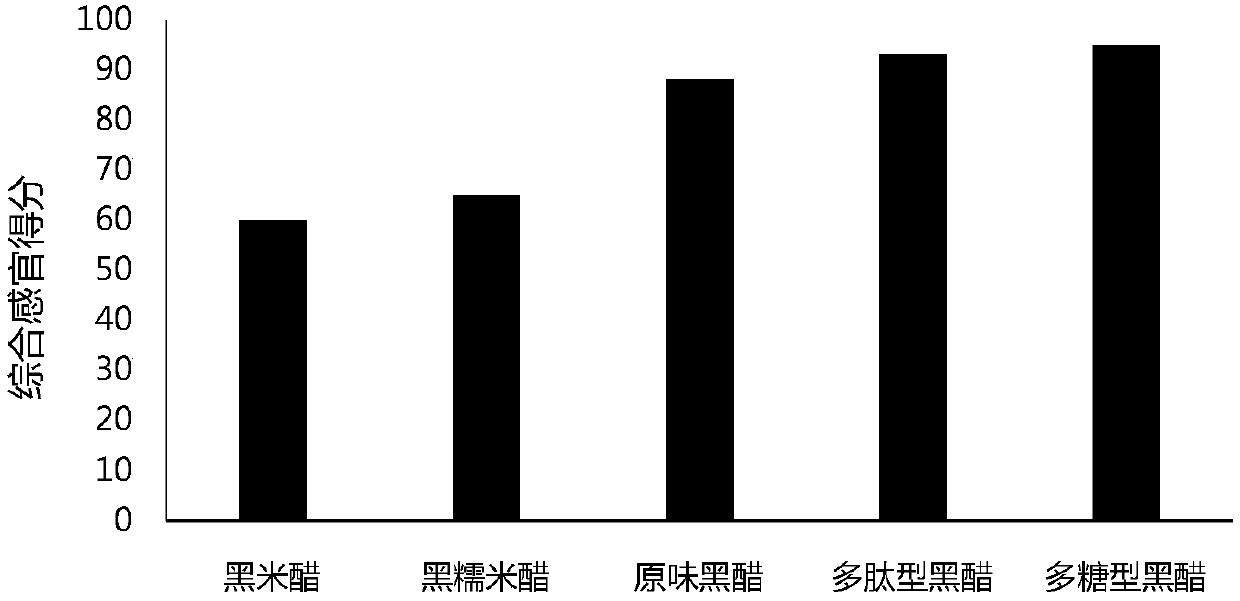

A processing method and nutritional technology, applied in the processing field of nutritional black vinegar, can solve the problems of few types of microorganisms, insufficient enzyme system, and single taste, and achieve the effects of easy digestion and absorption, expanded health care functions, and increased amino acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

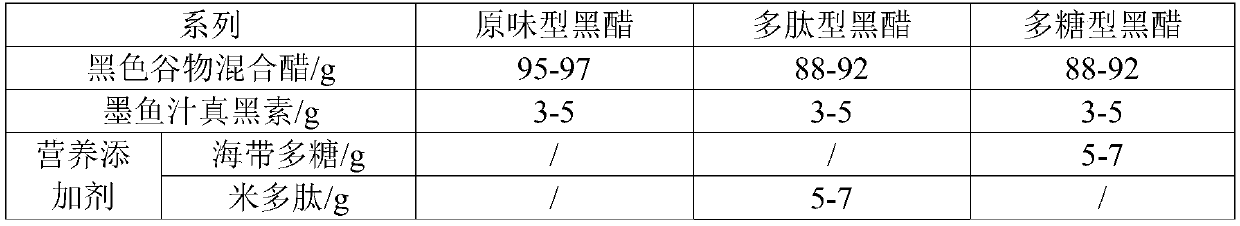

Examples

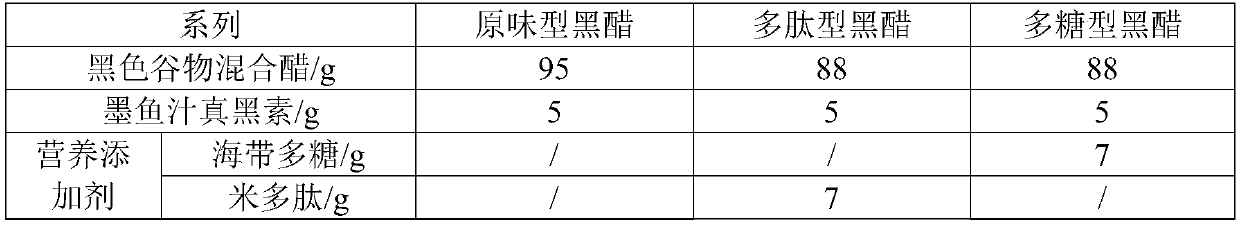

Embodiment 1

[0048] 1) Raw material pretreatment

[0049] Select black rice, black glutinous rice, rye, black tartary buckwheat and black corn with pure color and full grains as raw materials for extrusion and puffing. The technical conditions for extrusion and puffing are: the moisture content of the material is 25% and the feeding speed is 30g min -1 , the screw speed is 150r / min, and the temperature at the end of the barrel is 160°C. Then use an air mixer at a low speed of 3000r / min for 5 minutes, then at a high speed of 5000r / min for 8 minutes, and finally at a low speed of 2700r / min for 3 minutes, and the material is crushed to 50 mesh as the end point.

[0050] 2) Blending and saccharification

[0051] Mix the pulverized black grains with water at a weight ratio of 1:6, heat up to 40°C, add glucoamylase at an inoculation amount of 600U / g, and incubate in a thermostat at 40°C for 8 hours.

[0052] 3) Alcoholic fermentation

[0053] Weigh 3.0 g of active dry yeast, add it to 100 ml o...

Embodiment 2

[0067] 1) Raw material pretreatment

[0068] Select black rice, black glutinous rice, rye, black tartary buckwheat and black corn with pure color and full grain as raw materials for extrusion and expansion. The technical conditions for extrusion and expansion are: the moisture content of the material is 25%, and the feeding speed is 30g. min -1 , the screw speed is 150r / min, and the temperature at the end of the barrel is 160°C. Then use an air mixer at a low speed of 3000r / min for 10min, then at a high speed of 5000r / min for 5min, and finally at a low speed of 2700r / min for 5min, and the material is crushed to 50 mesh as the end point.

[0069] 2) Blending and saccharification

[0070] Mix the pulverized black grains with water at a weight ratio of 1:8, heat up to 40°C, add glucoamylase at an inoculation amount of 600U / g, and incubate in a thermostat at 30°C for 10 hours.

[0071] 3) Alcoholic fermentation

[0072] Weigh 3.0 g of active dry yeast, add it to 100 ml of sucr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com