Preparation method for cesium-stannous halogen perovskite film material

A thin-film material and perovskite technology, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problem of unstable product performance, good crystal quality and optical quality, and limit cesium tin halide perovskite Material development and other issues, to achieve the effect of good crystal quality and optical quality, single crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a cesium tin halide perovskite film material, which includes:

[0030] Combine CsX and SnX 2 Put the mixed powder and substrate of the CVD tube furnace into the CVD tube furnace, evacuate, then inject argon gas at 150-500 standard mL / min, and keep the pressure in the furnace chamber at 50-300Pa, and then heat the furnace chamber to Reaction at 500~800℃, and quenching after the reaction, to obtain cesium tin halide perovskite film material;

[0031] Wherein, the X is Cl, Br or I.

[0032] In the present invention, the CsX and SnX 2 The molar ratio of is preferably (0.3 to 1.2): (0.3 to 1.2), more preferably (0.5 to 1): (0.5 to 1), and most preferably (0.6 to 0.9): (0.6 to 0.9).

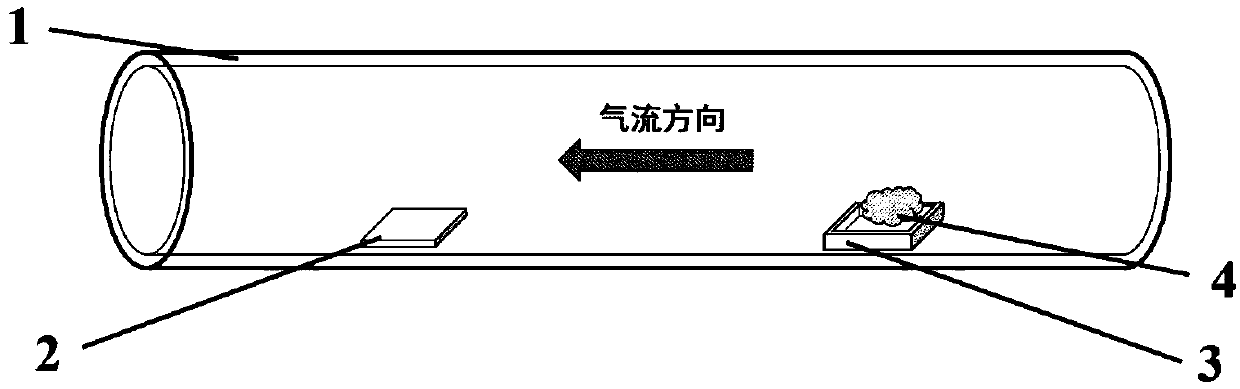

[0033] In the present invention, the present invention does not have special requirements for the type of CVD tube furnace, and all CVD tube furnaces known in the art can be used. Among them, the present invention has no special requirements for the method o...

Embodiment 1

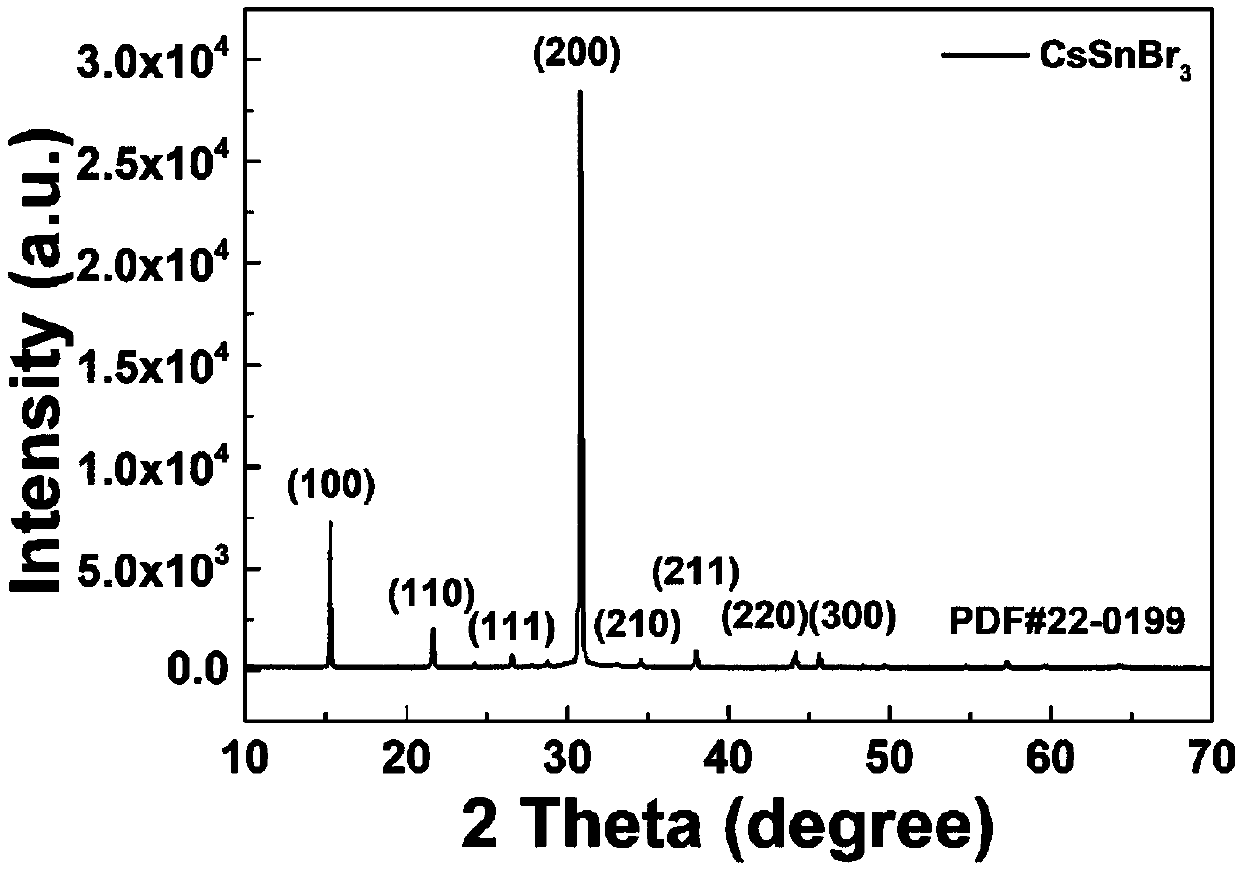

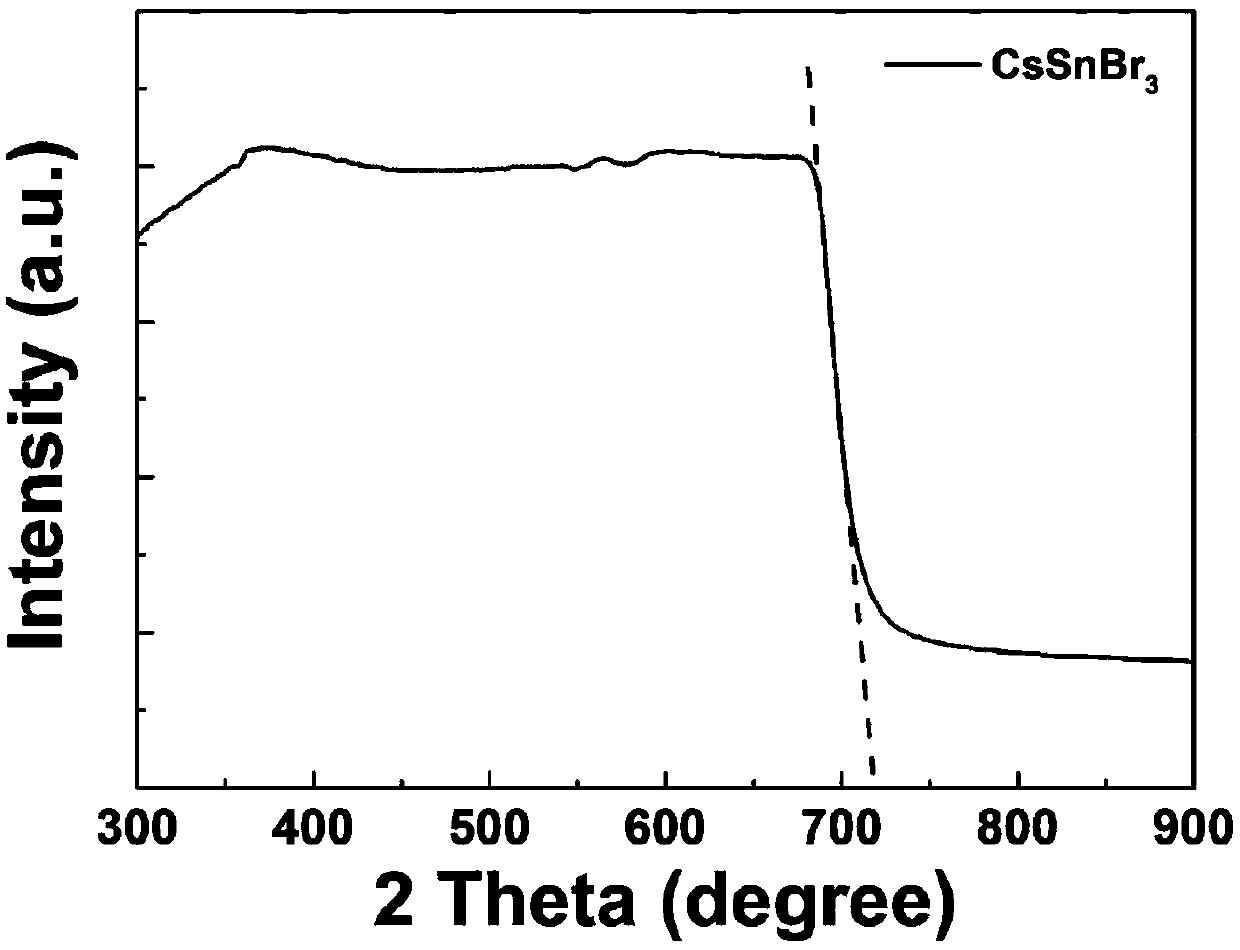

[0041] The cesium halide and tin halide (CsBr and SnBr 2 ) Mix together at a molar ratio of 1:1 and grind to a uniform powder. The mixed powder is loaded into a ceramic boat and placed in a CVD tube furnace. The ITO substrate is placed in the downstream direction of the ceramic boat carrying the raw material powder in the tube furnace. Then, the air pressure in the tube furnace is pumped to 20 Pa with a mechanical pump, and then 300 standard ml / min of high-purity argon (99.99%) is introduced into the furnace cavity as the protective gas and carrier gas. After the argon gas is introduced, the pressure in the furnace cavity is maintained at 140 Pa. Increase the temperature in the tube furnace cavity to 700 at a rate of 25°C / min and keep it for 20 minutes. When the growth is completed, stop heating to cool down the furnace cavity naturally and maintain the growth airflow and air pressure. After the temperature in the furnace cavity drops to 380°C, the pressure in the furnace ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com