High-toughness flame-retardant polypropylene material and preparation method thereof

A polypropylene material, flame-retardant technology, applied in the manufacture of fire-resistant and flame-retardant filaments, single-component polyolefin artificial filaments, fiber types, etc., can solve the problem of poor resistance to deformation and fracture, and poor compatibility , material rigidity and other problems, to achieve the effect of small physical and mechanical properties, good UV resistance and heat insulation, and improved flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

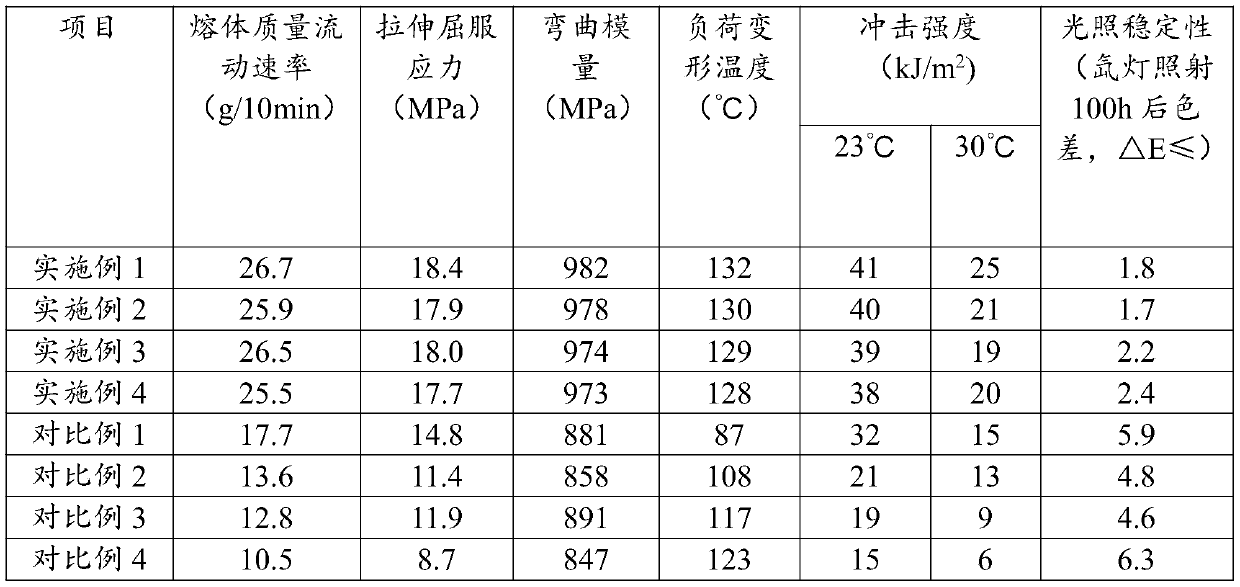

Examples

Embodiment 1

[0035] A high-toughness flame-retardant polypropylene material of the present embodiment includes the following raw materials in parts by weight: 146 parts of modified isotactic polypropylene, FeTiO 3 17 parts of titanium dioxide-sisal fiber composite light stabilizer, 50 parts of ester-soluble chlorinated polypropylene resin solution, 13 parts of adhesion promoter γ-glycidyl etheroxypropyl trimethoxysilane. Wherein, the ester-soluble chlorinated polypropylene resin solution is prepared by mixing the ester-soluble chlorinated polypropylene resin and the diluent according to a mass ratio of 1:10; wherein, the chlorine content of the ester-soluble chlorinated polypropylene resin is 22 ± 1.5%, The viscosity is 40-60cps, and the diluent is composed of n-propyl acetate, ethyl acetate, and propylene glycol methyl ether acetate in a mass ratio of 6:4:1.

[0036] The preparation method of described modified isotactic polypropylene comprises the following steps:

[0037] (1) Mixing mo...

Embodiment 2

[0049] A high-toughness flame-retardant polypropylene material of the present embodiment includes the following raw materials in parts by weight: 152 parts of modified isotactic polypropylene, FeTiO 3 / 19 parts of titanium dioxide-sisal fiber composite light stabilizer, 47 parts of ester-soluble chlorinated polypropylene resin solution, 13 parts of adhesion promoter γ-glycidyl etheroxypropyl triethoxysilane. Wherein, the ester-soluble chlorinated polypropylene resin solution is prepared by mixing the ester-soluble chlorinated polypropylene resin and the diluent according to a mass ratio of 1:10; wherein, the chlorine content of the ester-soluble chlorinated polypropylene resin is 22 ± 1.5%, The viscosity is 40-60cps, and the diluent is composed of n-propyl acetate, ethyl acetate, and propylene glycol methyl ether acetate in a mass ratio of 6:4:1.

[0050] The preparation method of the modified isotactic polypropylene is the same as in Example 1.

[0051] FeTiO 3 The preparat...

Embodiment 3

[0057] A high-toughness flame-retardant polypropylene material of the present embodiment comprises the following raw materials in parts by weight: 145 parts of modified isotactic polypropylene, FeTiO 3 / 23 parts of titanium dioxide-sisal fiber composite light stabilizer, 52 parts of ester-soluble chlorinated polypropylene resin solution, 9 parts of adhesion promoter-methacryloxypropyl triethoxysilane. Wherein, the ester-soluble chlorinated polypropylene resin solution is prepared by mixing the ester-soluble chlorinated polypropylene resin and the diluent according to a mass ratio of 1:10; wherein, the chlorine content of the ester-soluble chlorinated polypropylene resin is 22 ± 1.5%, The viscosity is 40-60cps, and the diluent is composed of n-propyl acetate, ethyl acetate, and propylene glycol methyl ether acetate in a mass ratio of 6:4:1.

[0058] The preparation method of the modified isotactic polypropylene is the same as in Example 1.

[0059] FeTiO 3 The preparation meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com