Method for improving liquid injection efficiency in battery preparation process and improving battery cell performance

A preparation process and liquid injection technology, which is applied in the manufacture of electrolyte batteries, battery components, non-aqueous electrolyte batteries, etc., can solve the problems of unfavorable industrial production and application, increasing the absorption rate of battery pole pieces, and cumbersome operation process, etc. Achieve the effect of solving the long time-consuming activation, eliminating the activation steps, and improving the efficiency of liquid injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a method for improving the liquid injection efficiency and improving the performance of the battery cell during the preparation of the cylindrical battery, including:

[0042] (1) Prepare a cylindrical battery semi-finished product including a battery cell, a casing, a liquid injection hole and a cap.

[0043] Among them, the battery core is wound by a positive electrode sheet, a separator and a negative electrode sheet, and the separator separates the positive electrode sheet and the negative electrode sheet.

[0044] (2) Heat the electrolyte to 50°C before injecting the liquid, and then inject the cell from the liquid injection hole;

[0045] (3) Sealing, coating, and formation to obtain a cylindrical battery.

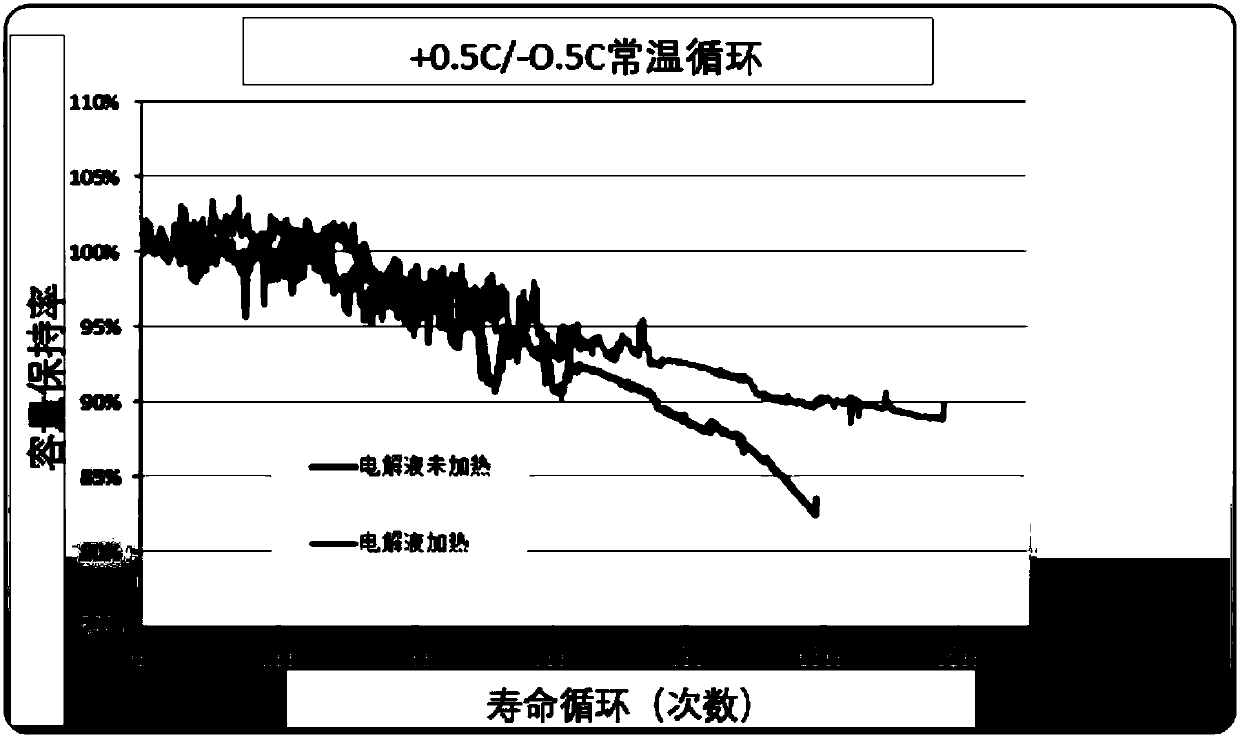

[0046] The preparation of the cylindrical battery in this example does not require an activation step. Compared with the process of preparing the battery directly at room temperature (~25°C) without heating the electrolyte in Comparat...

Embodiment 2

[0049] This embodiment provides a method for improving the liquid injection efficiency and improving the performance of the battery cell during the preparation of the cylindrical battery, including:

[0050] (1) Prepare a cylindrical battery semi-finished product including a battery cell, a casing, a liquid injection hole and a cap.

[0051] Among them, the battery core is wound by a positive electrode sheet, a separator and a negative electrode sheet, and the separator separates the positive electrode sheet and the negative electrode sheet.

[0052] (2) Heat the electrolyte to 45°C before injecting the liquid, and then inject the cell from the liquid injection hole;

[0053] (3) Sealing, coating, and formation to obtain a cylindrical battery.

[0054] In this example, no activation step is required to prepare the cylindrical battery. Compared with the process of preparing the battery directly at room temperature (~25°C) without heating the electrolyte in Comparative Example ...

Embodiment 3

[0057] This embodiment provides a method for improving the liquid injection efficiency and improving the performance of the battery cell during the preparation of the cylindrical battery, including:

[0058] (1) Prepare a cylindrical battery semi-finished product including a battery cell, a casing, a liquid injection hole and a cap.

[0059] Among them, the battery core is wound by a positive electrode sheet, a separator and a negative electrode sheet, and the separator separates the positive electrode sheet and the negative electrode sheet.

[0060] (2) Heat the electrolyte to 55°C before injecting the liquid, and then inject the cell from the liquid injection hole;

[0061] (3) Sealing, coating, and formation to obtain a cylindrical battery.

[0062] The preparation of cylindrical batteries in this example does not require an activation step. Compared with the process of preparing batteries directly at room temperature (~25°C) without heating the electrolyte in Comparative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com