Double-layer solid electrolyte composite membrane with polyacrylonitrile as the main body, its preparation method and application

A solid electrolyte, polyacrylonitrile technology, applied in solid electrolyte, electrolyte battery manufacturing, non-aqueous electrolyte and other directions, can solve the problems of low electrical conductivity and poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Dissolve PAN, PEO and LATP in DMF in a certain proportion, and magnetically stir to form a homogeneous solution. The mass ratio of PAN to PEO is 1:1, and LATP is 10% of the sum of the mass of PAN and PEO;

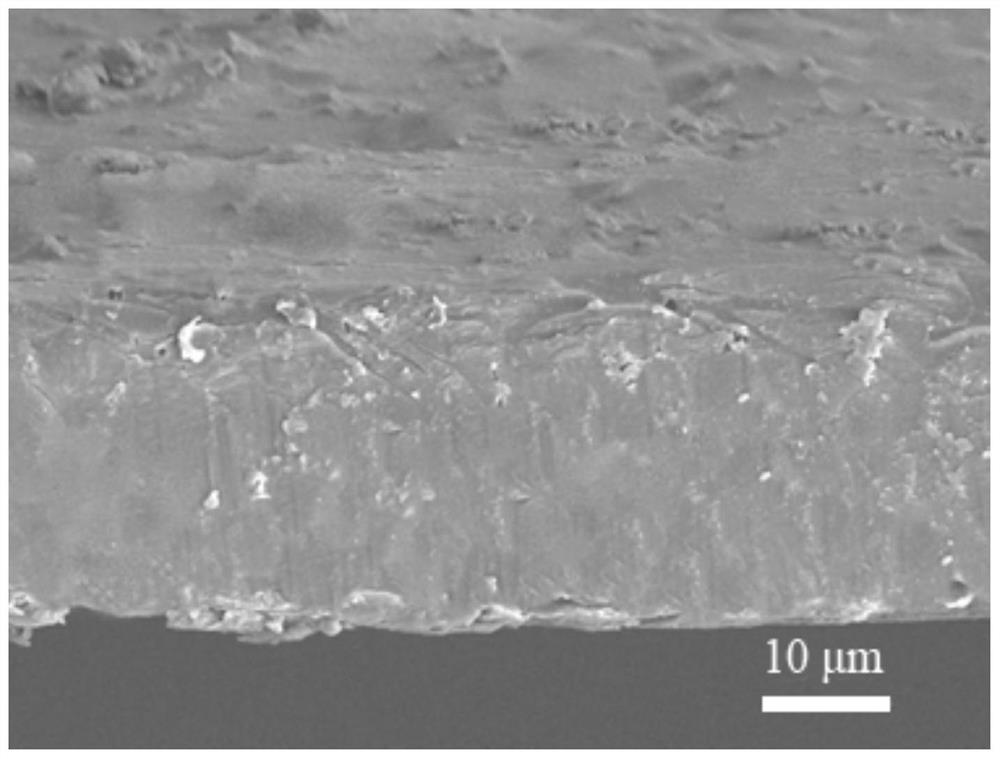

[0042] 2) Apply the homogeneous solution obtained in step 1) on a glass plate with a scraper, and dry it at 60°C for 10 minutes to obtain the first layer of electrolyte, which is named PPL electrolyte layer;

[0043] 3) Dissolve PAN and LATP in DMF in a certain proportion, and magnetically stir to form a homogeneous solution. The LATP is 10% of the mass of PAN; the resulting solution is scraped and coated on the PPL electrolyte layer obtained in step 2) with a scraper to obtain a PL electrolyte layer;

[0044] 4) Put the double-layer electrolyte obtained in step 3) in a vacuum drying oven at 60°C for 12 hours in a vacuum to obtain a double-layer solid electrolyte composite membrane (ie, a double-layer solid electrolyte composite membrane mainly composed of polyacr...

Embodiment 2

[0050] 1) Dissolve PAN, PEO and LATP in DMF in a certain proportion, and magnetically stir to form a homogeneous solution. The ratio of PAN to PEO mass is 1:1, and LATP is 20% of the sum of PAN and PEO mass;

[0051] 2) Apply the solution obtained in step 1) on a glass plate with a scraper, and dry at 60°C for 10 minutes to obtain the first layer of PPL electrolyte;

[0052] 3) Dissolve PAN and LATP in DMF in a certain proportion, and magnetically stir to form a homogeneous solution. The LATP is 20% of the mass of PAN; the solution obtained above is scraped and coated on the PPL electrolyte layer obtained in step 2) with a scraper to obtain the PL electrolyte layer;

[0053] 4) The double-layer electrolyte obtained in step 3) was vacuum-dried in a vacuum oven at 60° C. for 12 hours to obtain a composite film of double-layer solid electrolyte, called PPL-PL. The thickness of this electrolyte is 25 μm±1.

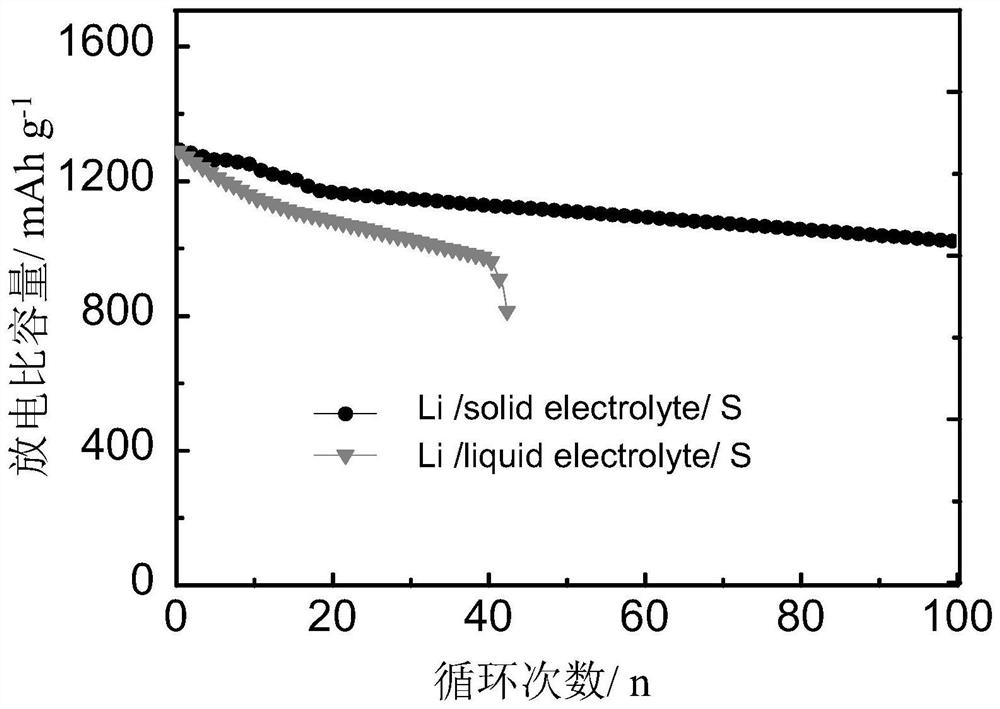

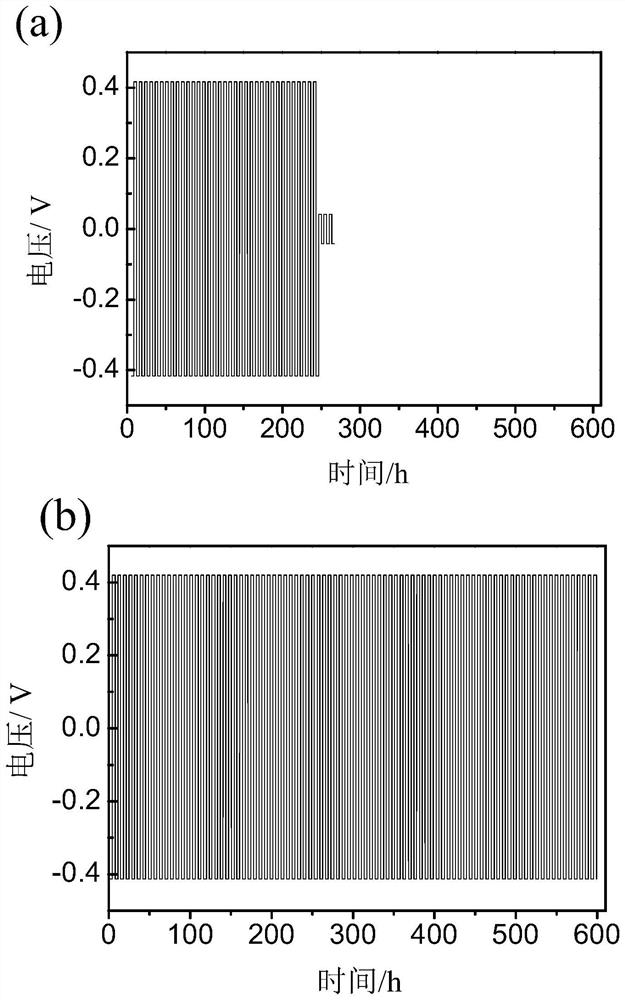

[0054] 5) The gel polymer electrolyte material is punched into a disc ...

Embodiment 3

[0057] 1) Dissolve PAN, PEO and LATP in DMF in a certain proportion, and magnetically stir to form a homogeneous solution. The ratio of PAN to PEO mass is 1:1, and LATP is 30% of the sum of PAN and PEO mass;

[0058] 2) Apply the solution obtained in step 1) on a glass plate with a scraper, and dry at 60°C for 10 minutes to obtain the first layer of PPL electrolyte;

[0059] 3) Dissolve PAN and LATP in DMF in a certain proportion, and magnetically stir to form a homogeneous solution. The LATP is 30% of the mass of PAN; the solution obtained above is scraped and coated on the PPL electrolyte layer obtained in step 2) with a scraper to obtain the PL electrolyte layer;

[0060] 4) The double-layer electrolyte obtained in step 3) was vacuum-dried in a vacuum oven at 60° C. for 12 hours to obtain a composite film of double-layer solid electrolyte, called PPL-PL. The thickness of this electrolyte is 25 μm±1.

[0061] 5) The gel polymer electrolyte material is punched into a disc ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com