A preparation method of a hierarchical porous carbon-based catalyst for catalytically upgrading coal tar

A carbon-based catalyst and catalytic upgrading technology, applied in physical/chemical process catalysts, catalytic cracking, chemical instruments and methods, etc., can solve the problems of unfavorable reactant diffusion active site contact, complex production process, catalyst deactivation and other problems , to achieve the effects of low preparation cost, simple production process, and promotion of catalytic cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

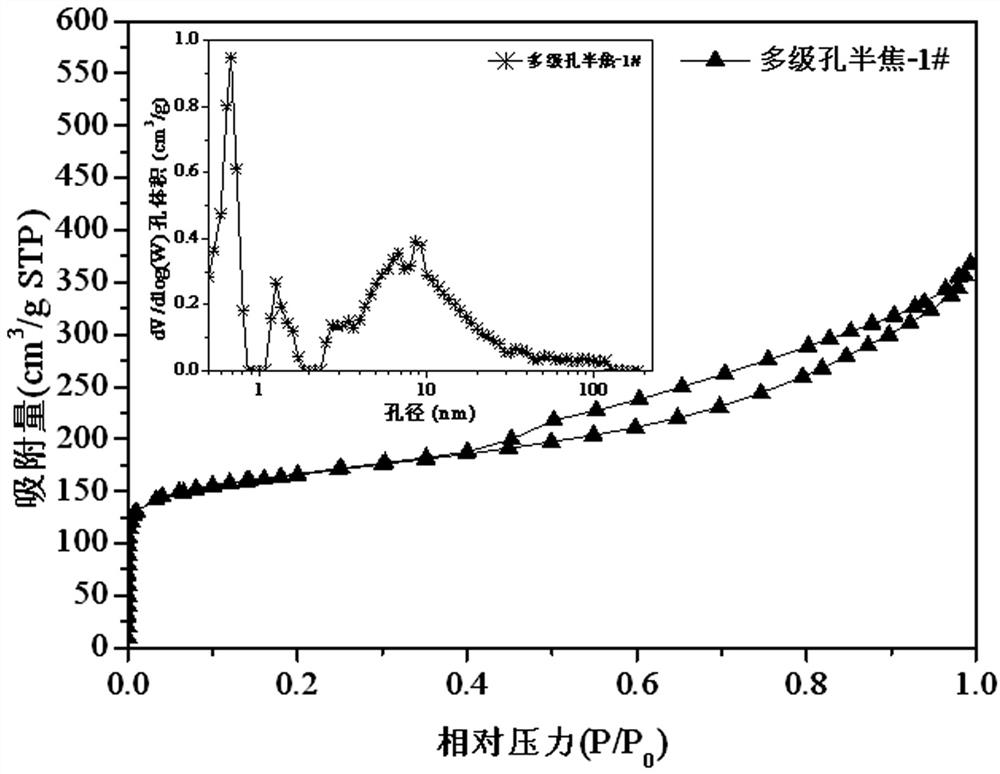

Embodiment 1

[0036] (1) The long-flame coal Wucaiwan coal in the Wucaiwan area of Xinjiang was selected as the raw material. After the coal sample was crushed, ground and sieved, the sample with a particle size of less than 0.178mm was selected for the experiment.

[0037] (2) The raw coal of Wucai Bay is treated with acid elution and demineralization. Stir 60g of coal sample with 600mL of hydrochloric acid with a concentration of 6mol / L at 25°C for 12h, filter, wash and dry, then soak the coal sample with 600mL of hydrofluoric acid with a concentration of 7.6mol / L at 25°C Stir for 12 hours, filter, wash and dry to obtain demineralized Wucaiwan coal.

[0038] (3) Weigh 11g demineralized Wucaiwan coal and 0.7793g Ca(NO 3 ) 2 4H 2 O was mixed in a beaker, and deionized water was added to submerge the sample. After stirring at 25 °C for 12 h, the resulting mixture was dried at 70 °C to obtain demineralized Wucaiwan coal loaded with calcium nitrate.

[0039] (4) Put the demineralized Wuc...

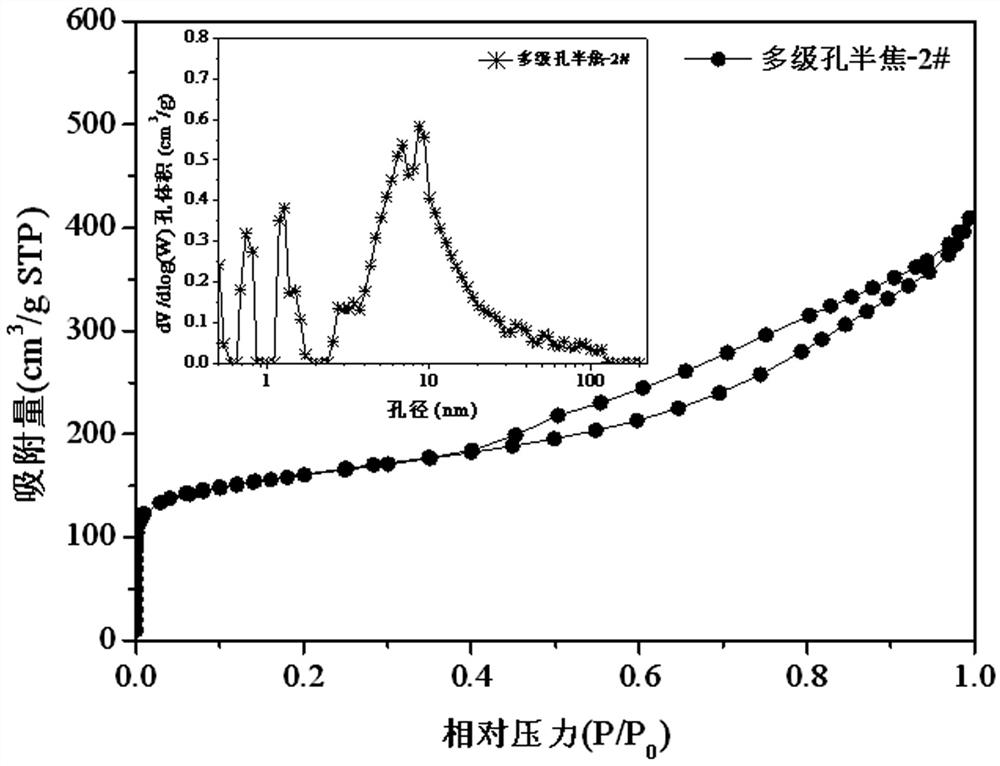

Embodiment 2

[0044] (1) The long-flame Yining coal in the Yining area of Xinjiang was selected as the raw material. After the coal sample was crushed, ground, and sieved, the sample with a particle size of less than 0.178 mm was selected for the experiment.

[0045] (2) Carry out acid elution mineral treatment on Yining raw coal. Stir 40 g of coal sample with 400 mL of hydrochloric acid with a concentration of 6 mol / L at 25°C for 12 hours, filter, wash, and dry, then soak the coal sample washed with hydrochloric acid and 400 mL of hydrofluoric acid with a concentration of 7.6 mol / L at 25 °C Stir at ℃ for 12 hours, filter, wash and dry to obtain demineralized Yining coal.

[0046] (3) Weigh 9g of demineralized Yining coal and 0.4757g of Ca(CH 3 COO) 2 ·H 2 O was mixed in a beaker, and deionized water was added to submerge the sample. After stirring at 25 °C for 12 h, the resulting mixture was dried at 70 °C to obtain demineralized Yining coal loaded with calcium acetate.

[0047] (4) ...

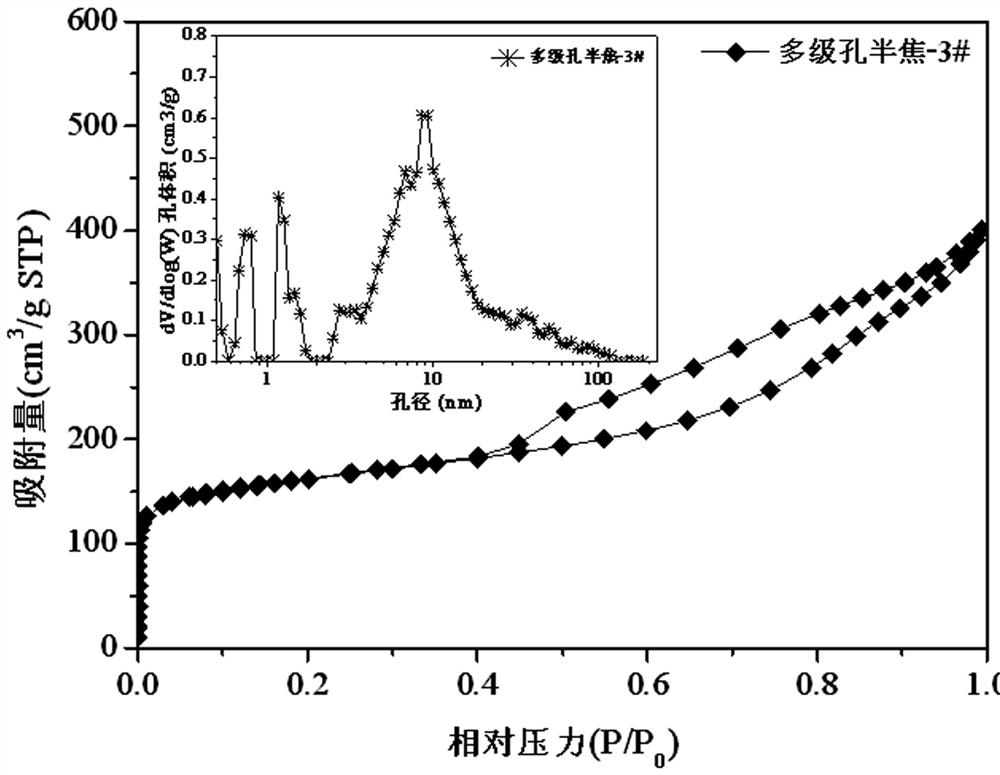

Embodiment 3

[0053] (1) The long-flame coal Wucaiwan coal in the Wucaiwan area of Xinjiang was selected as the raw material. After the coal sample was crushed, ground and sieved, the sample with a particle size of less than 0.178mm was selected for the experiment.

[0054] (2) The raw coal of Wucai Bay is treated with acid elution and demineralization. Stir 60g of coal sample with 600mL of hydrochloric acid with a concentration of 6mol / L at 25°C for 12h, filter, wash and dry, then soak the coal sample with 600mL of hydrofluoric acid with a concentration of 7.6mol / L at 25°C Stir for 12 hours, filter, wash and dry to obtain demineralized Wucaiwan coal.

[0055] (3) Weigh 12g of demineralized Wucaiwan coal and 0.2223g of Ca(OH) 2 Mix in a beaker, add deionized water to immerse the sample, stir at 25°C for 12h, and dry the resulting mixture at 70°C to obtain demineralized Wucaiwan coal loaded with calcium hydroxide.

[0056] (4) The demineralized Wucaiwan coal loaded with calcium hydroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com