A kind of preparation method of nanowire array device

A nanowire array and nanowire technology, which is applied in the field of preparation of nanowire array devices, can solve problems such as process difficulties, and achieve the effect of reducing process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described below in conjunction with examples, so as to better understand the present invention.

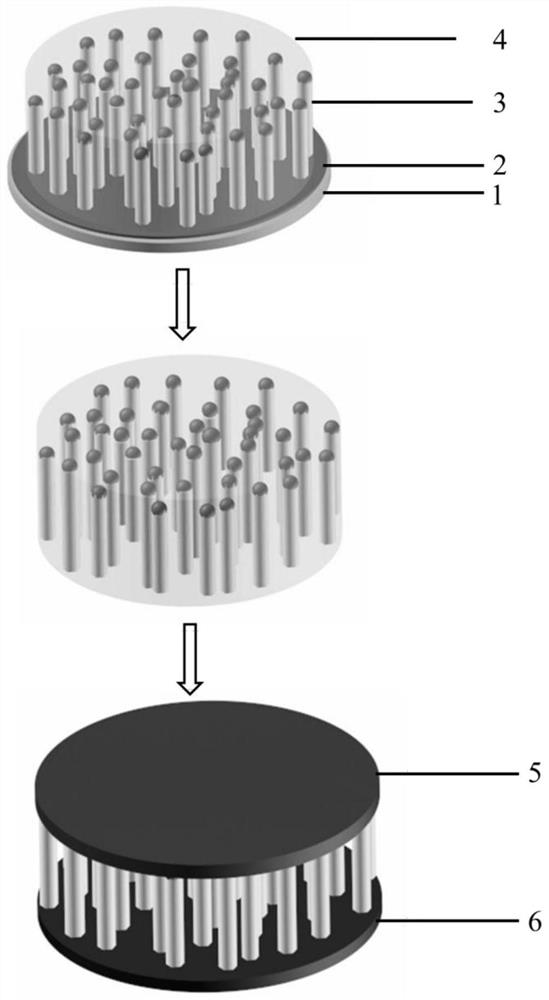

[0019] The invention proposes a method for preparing a nanowire array device. The method first obtains a migratable nanowire array material, and the method for obtaining the nanowire array material is by growing Al on a GaAs substrate. x Ga 1-x As thin film material as sacrificial layer, Al x Ga 1-x The composition of Al in As is 0.6≤x≤1, the nanowire material is grown on Al x Ga 1-x On the As thin film, spin-coat the PMMA material dissolved in acetone solution on the surface of the sample after the growth of the nanowire material and let it dry in the air. At this time, the PMMA material is solidified to fix the nanowire material, and then the nanowire material sample fixed with the PMMA material Put it into the HF acid corrosion solution, use HF acid to Al x Ga 1-x As thin film material has corrosion effect, but ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com