Preparation method of high-temperature capacity spinel lithium manganese oxide

A technology of spinel lithium manganese oxide and capacity, applied in chemical instruments and methods, manganese compounds, structural parts, etc., can solve the problems of reducing specific capacity, etc., and achieve the effect of improving high temperature performance, obvious stabilization effect and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

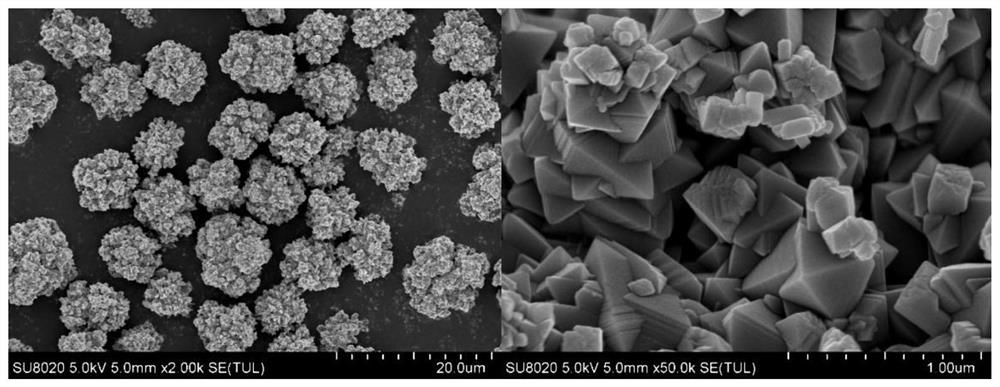

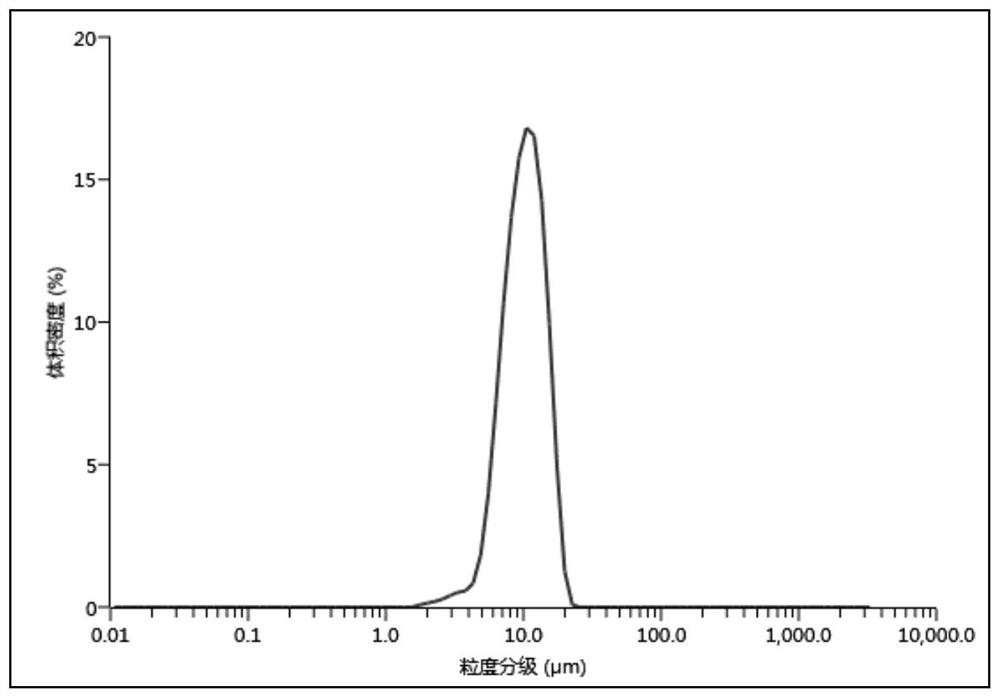

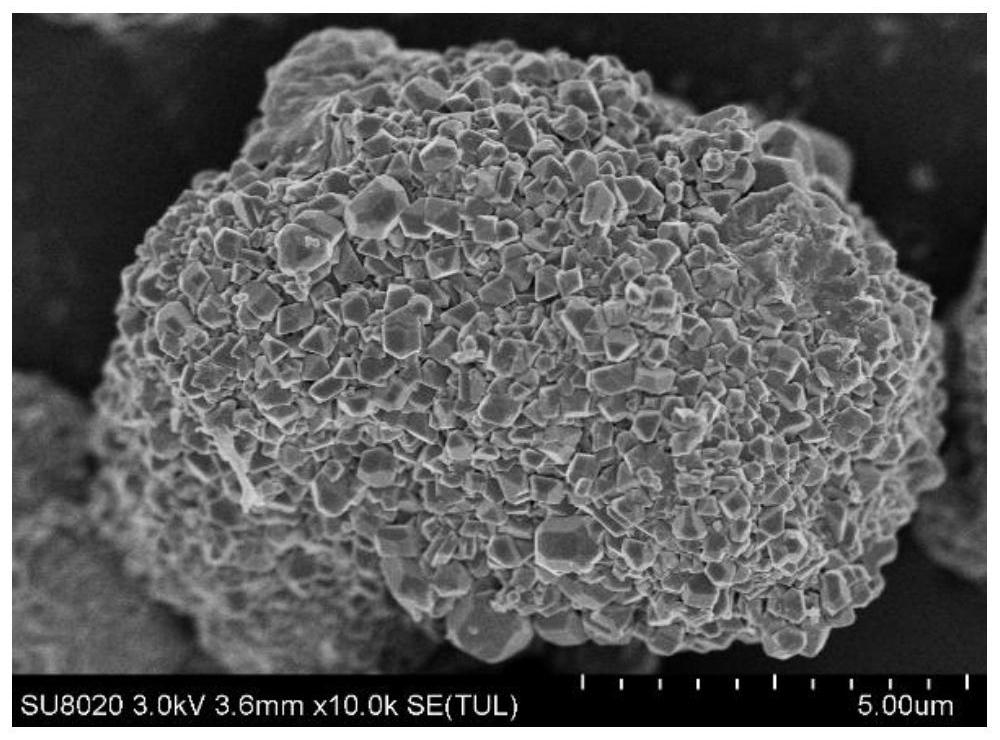

[0044] A kind of preparation method of high-temperature capacity spinel lithium manganate of the present invention, prepares high-temperature spinel lithium manganate, according to chemical formula Li 1+x mn 2-y MyO 4 Lithium-manganese ratio.

[0045] Use the following method steps:

[0046] 1) Synthesis of trimanganese tetraoxide precursor,

[0047] Using the air oxidation liquid phase precipitation process, the manganese source solution, the impurity element M and the precipitant are placed in the reaction device for a mixed reaction, and the reaction temperature is controlled at 50-70 ° C to prepare the trimanganese tetraoxide precursor; Control the manganese source solution to be 0.53mol / L-1.0 mol / L; the manganese source solution is prepared by mixing complexing agent, dispersant, surfactant and manganese salt;

[0048] Controlling the complexing agent to be a mixture of EDTA-2Na with a concentration of 0.001-0.05mol / L and urea with a concentration of 0.001-0.1mol / L; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com