Modular normal-pressure electrochemical treatment device

A processing device and modular technology, which is used in the field of circulating water scale inhibition, chlorine removal, and scale removal, can solve the problems of limited processing capacity of equipment, increased area of cathode and anode plates, corrosion of equipment and pipelines, etc., so as to avoid eddy gas corrosion. , the effect of reducing water consumption and increasing processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

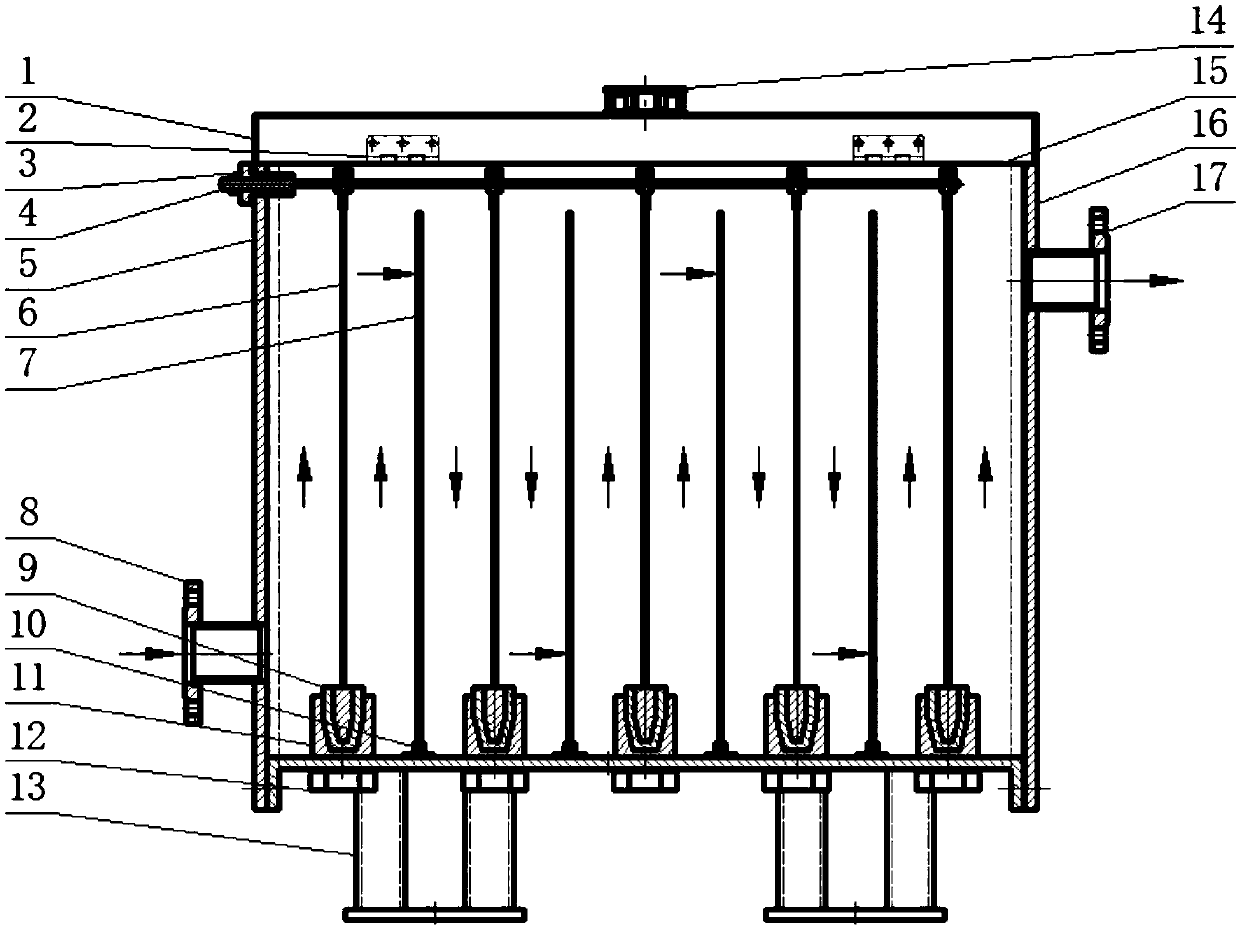

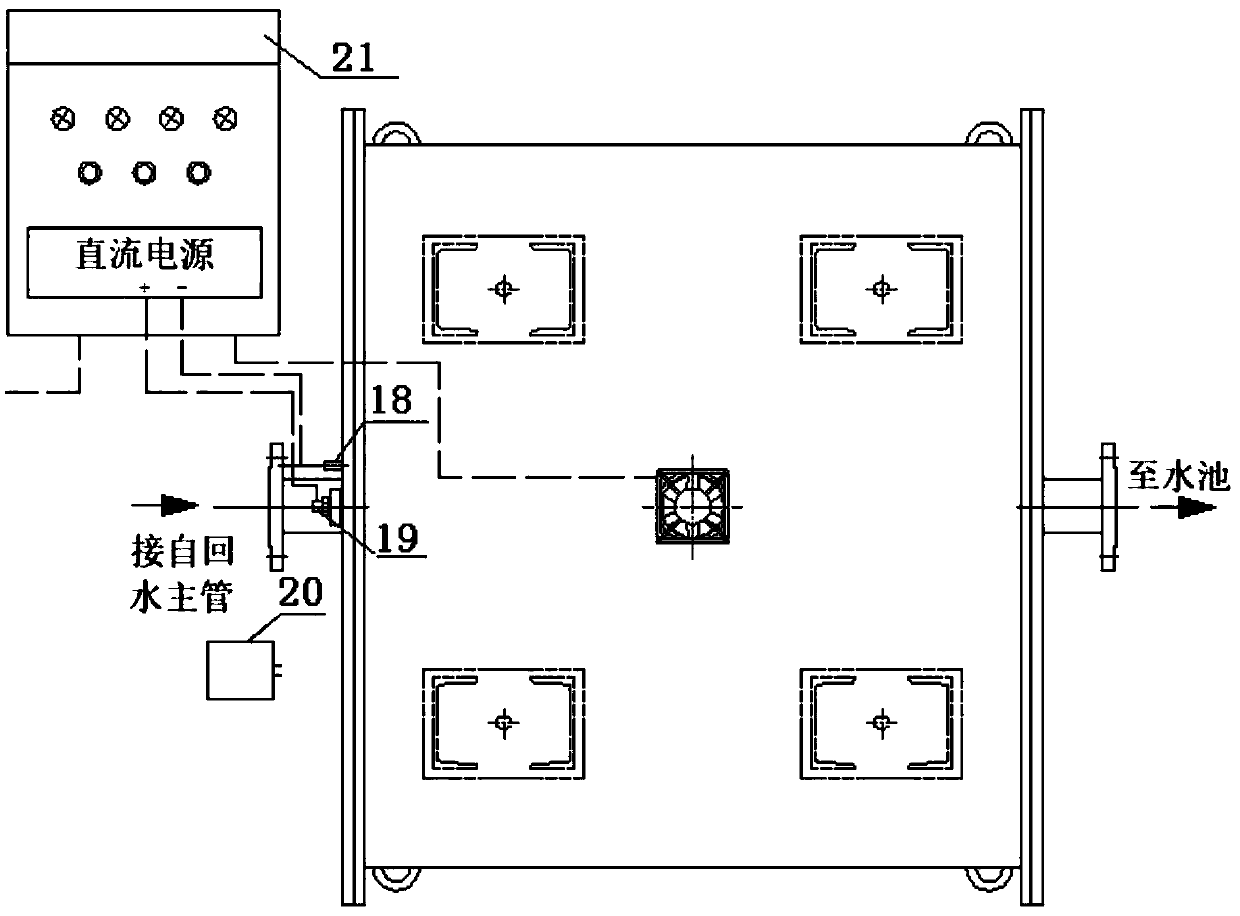

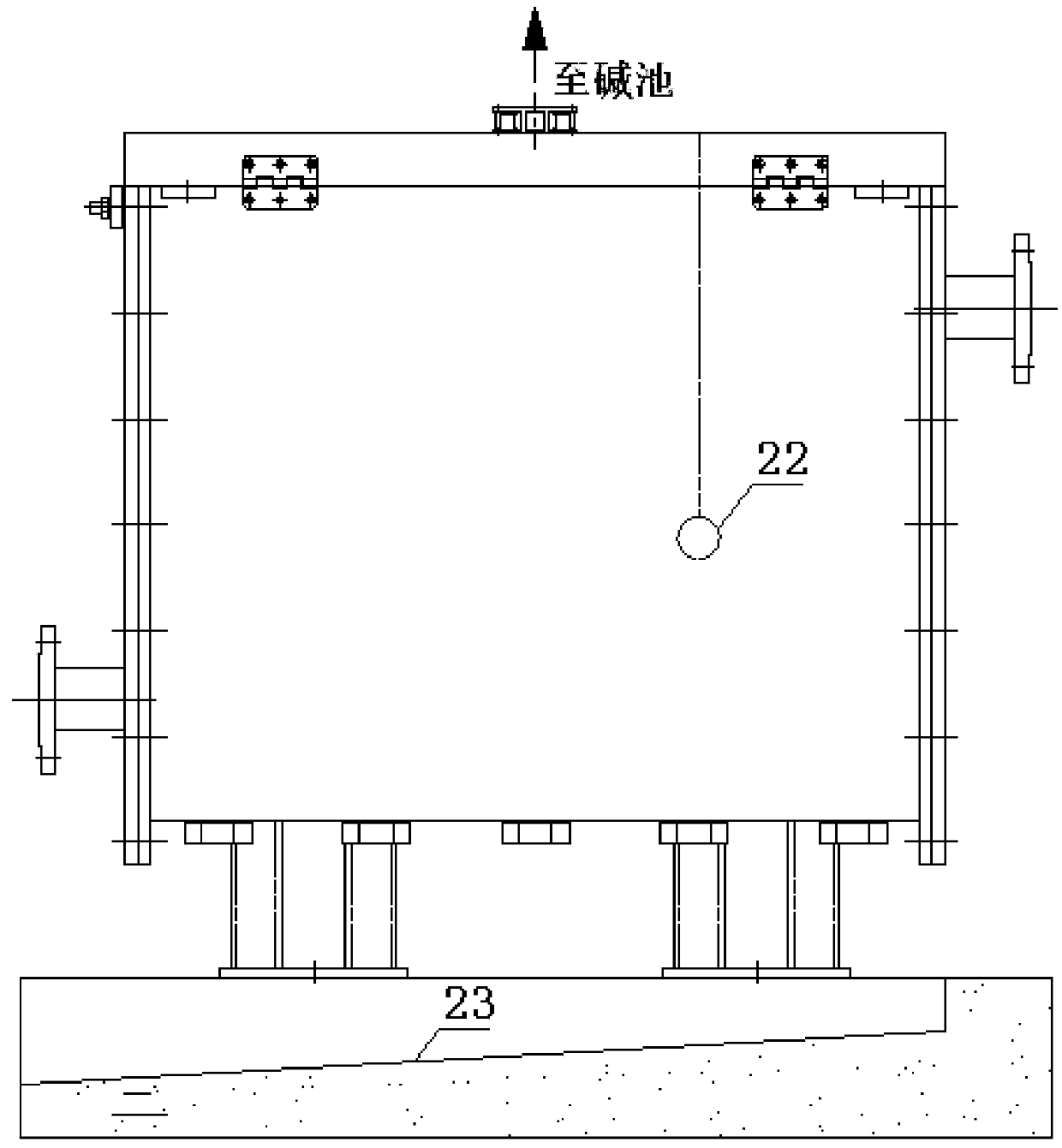

[0020] For a preferred embodiment, see Figure 1 to Figure 3 , a modularized atmospheric pressure electrochemical treatment device, comprising an open scale analysis tank, the interior of which is an accommodating space, a cover plate 1 is provided at the opening of the open scale analysis tank, and a water inlet is arranged on the open scale analysis tank end 8 and water outlet 17, the accommodating space near the water inlet area is the front section 5 of the open scale analysis tank, and the area near the water outlet is the rear section 16 of the open scale analysis tank, the front section 5 of the open scale analysis tank is connected to The area between the rear sections 16 of the open scale analysis tank is the middle section 15 of the open scale analysis tank, and the pole plate assembly is arranged in the middle section 15 of the open scale analysis water tank, and the pole plate assembly has several anode plates 6, and the anode The bottom of the plate 6 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com