System and method for treating high suspended matter mine water

The technology of a treatment system and treatment method is applied in the field of treatment systems for mine water with high suspended solids, which can solve the problems of high mining construction cost, complicated technological process and high technical requirements for operation, so as to save resources, prolong service life and improve treatment efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

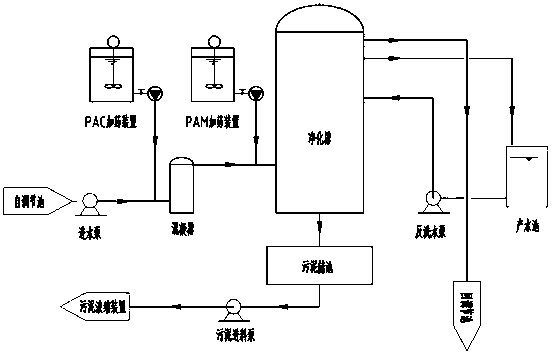

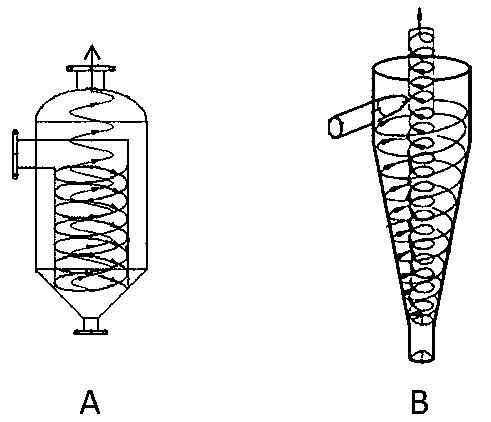

[0037] Such as figure 1 As shown, the present embodiment provides a treatment system for high-suspended-suspended mine water, which includes a regulating tank connected in sequence with water pipes, a water inlet pump, a coagulator, and a purifier. Wherein, the bottom of the purifier is connected with a sludge storage tank, and the top of the purifier is connected with a water production tank. A PAC dosing device is provided between the water inlet pump and the coagulator, and PAC is stored in the PAC dosing device to add PAC to the mine water before entering the coagulator. The coagulator is a swirling flow coagulator. The coagulator includes an upper end and a lower end. The inner diameter of the upper end is larger than the inner diameter of the lower end. The mine water enters the coagulator along the tangential direction of the upper end, and PAC and suspended particles are vortexed in the coagulator for a short time. Leave the coagulator after flash mixing. A PAM dosin...

Embodiment 2

[0042] The present embodiment provides a kind of treatment method of high suspended solids mine wastewater, which comprises the following steps:

[0043] Step 1: Lead the mine water into the adjustment tank for pretreatment, and then pump the mine water into the coagulator for coagulation.

[0044] Step 2: Introduce the coagulated mine water into the purifier, and in the purifier first perform the secondary cyclone centrifugation process of swirling downwards and then swirling upwards; during the downward swirling process, under the action of centrifugal force The suspended particles and alum flowers formed in the mine water are thrown to the wall of the device, and slide down the inner wall to the conical sludge storage area under the downward swirling flow and its own gravity, thereby removing most of the suspended solids; the mine water swirls downward When the flow reaches a certain level, it moves closer to the center to form an upward swirling flow, using the centrifugal...

Embodiment 3

[0046] The present embodiment provides a kind of treatment method of high suspended matter mine water, and it comprises the steps:

[0047] Step 1: Lead the mine water into the adjustment tank for pretreatment, add PAC to it after pretreatment, and then pump the mine water into the coagulator, the mine water enters the coagulator along the tangential direction of the inner wall of the coagulator, Swirling flash mixing is formed.

[0048] Step 2: Add PAM to the mine water that has undergone cyclone flash mixing, and then import the mine water into the purifier. In the purifier, firstly carry out the secondary cyclone centrifugation process of downward swirling and then upward swirling; downward swirling During the flow process, under the action of centrifugal force, the suspended particles and alum flowers formed in the mine water are thrown to the wall of the device, and slide down the inner wall to the conical sludge storage area under the downward swirling flow and its own g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com