Method for treating acid-containing and ammonia-containing wastewater and equipment system for implementing the method

A waste water and pretreatment technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, degassed water/sewage treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0079] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified. The experimental methods used in the following examples are conventional methods unless otherwise specified.

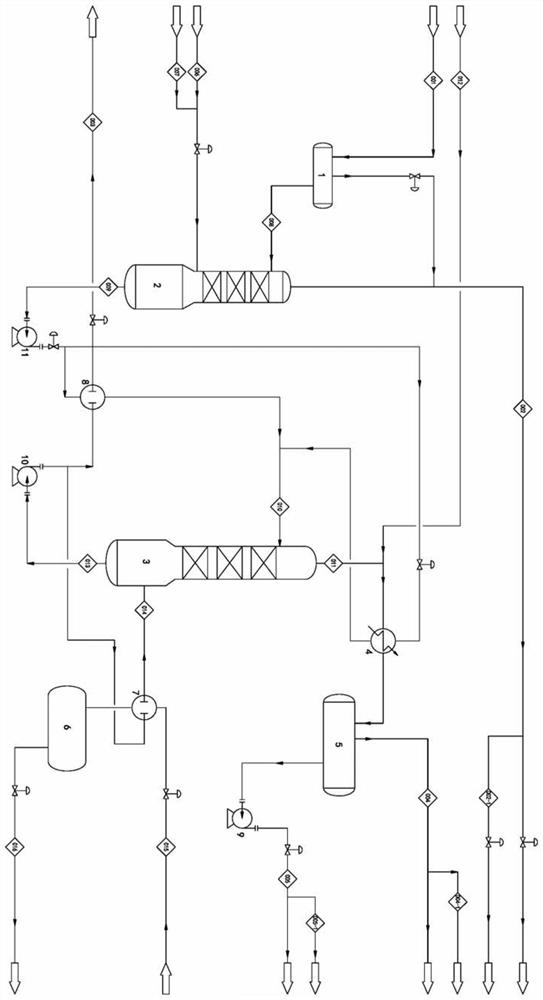

[0080] Attached below figure 1 The present invention is further described.

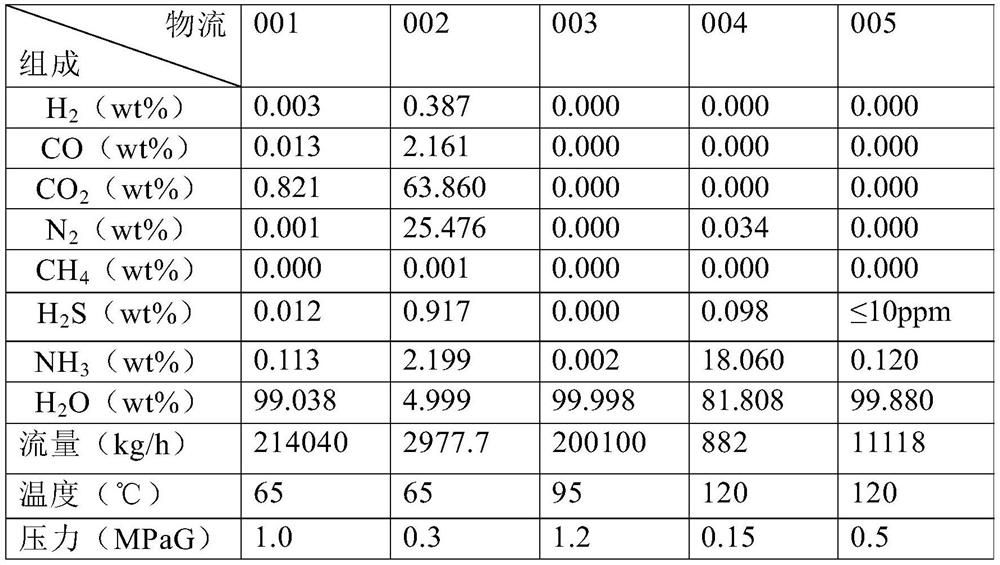

[0081] The ammonia washing water from the low-temperature methanol washing unit and the acid-containing ammonia-containing waste water from the CO conversion unit are mixed and sent as raw material (stream 001) to the condensate flash tank 1. Under the operating conditions of 0.7MPaG and 65°C, through After flash evaporation under reduced pressure, flash gas and condensate I were obtained.

[0082] The condensate I is sent to the top of the pretreatment tower 2, and under the operating conditions of 0.3MPaG and 65°C, nitrogen or natural gas (dynamically changing with the calorific value requirements of the acid gas) is used as the stripping medium to remove th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com