Quick-drying stone-like paint, quick-drying thick stone-like paint stone-like sheet and preparation method thereof

A real stone paint, quick-drying technology, applied in the field of painting, can solve the problems of lower water volatilization speed, slow drying speed, color change and poor shockproof effect of the lower layer, and achieve simple operation, short process and long preparation cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Another aspect of the present invention provides a method for preparing the quick-drying thick real stone paint imitation stone sheet described in the above embodiments, comprising the following steps:

[0039] Prepare mixed emulsion: mix thermosetting acrylic resin, water-based thermosetting amino resin and thermoplastic acrylic resin with a glass transition temperature of ≤5°C, and hydroxyethyl fiber with a viscosity of 3000-10000mpa·s and a concentration of 1%-3% Aqueous solution of plain ether, one or more of alkali-swellable thickeners or polyurethane thickeners, deionized water and auxiliary agents are fully dispersed and mixed uniformly to obtain a mixed emulsion for use;

[0040] Preparation of quick-drying real stone paint: Gradually and slowly add natural colored sand or sintered colored sand to the mixed emulsion, the weight ratio of the mixed emulsion to natural colored sand or sintered colored sand is 1: (2-4), after Stir evenly without agglomeration to obt...

Embodiment 1

[0045] 1. Prepare mixed emulsion:

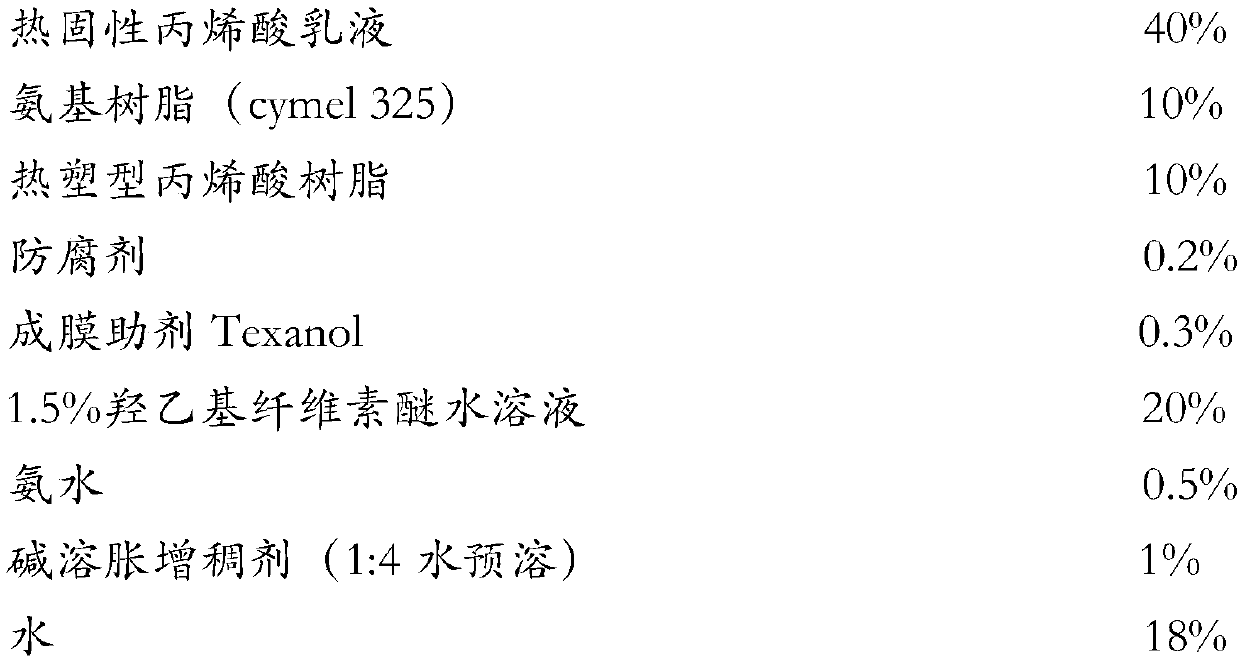

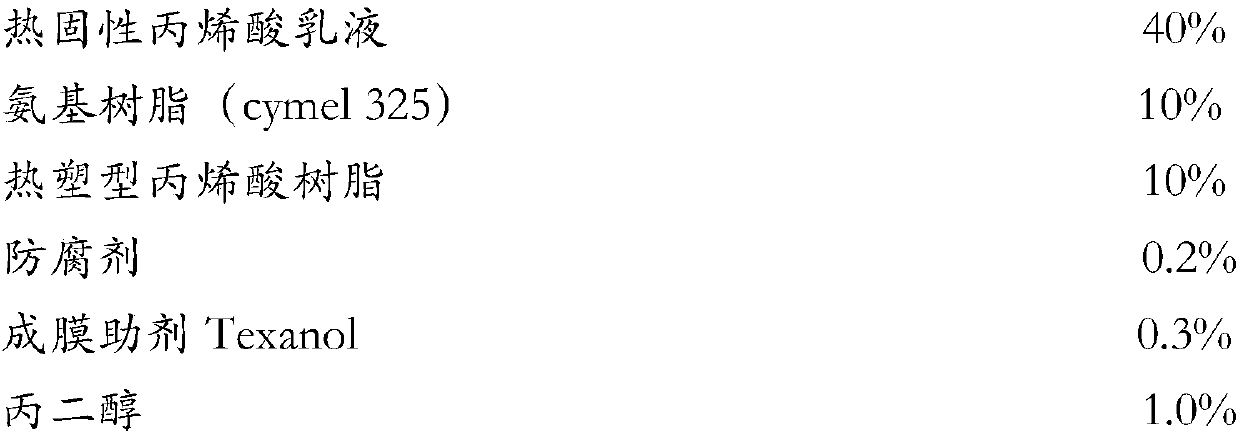

[0046] The mixed emulsion formula is:

[0047]

[0048] Add thermosetting acrylic emulsion, amino resin (the water-based thermosetting amino resin in this example refers to Cymel 325 amino resin) and thermoplastic acrylic resin (Tg is less than or equal to 5°C) in a clean reaction kettle according to the above formula. , and open the disperser at a low speed to stir the three emulsions evenly;

[0049] Then gradually turn on the medium-high speed of the disperser (about 500-700 rpm), and add preservatives in turn [the preservatives are isothiazolinones such as Kathon (5-chloro-2-methyl-4-isothiazoline- 3-ketone), one or more mixtures of BIT (1,2-phenylpropylisothiazolin-3-one)] and 1.5% hydroxyethyl cellulose aqueous solution (the aqueous solution preparation method is: high-speed dispersion in formula water Slowly add the hydroxyethyl cellulose ether powder under the environment, and disperse at a high speed to form an aqueous solution w...

Embodiment 2

[0056] 1. Prepare mixed emulsion:

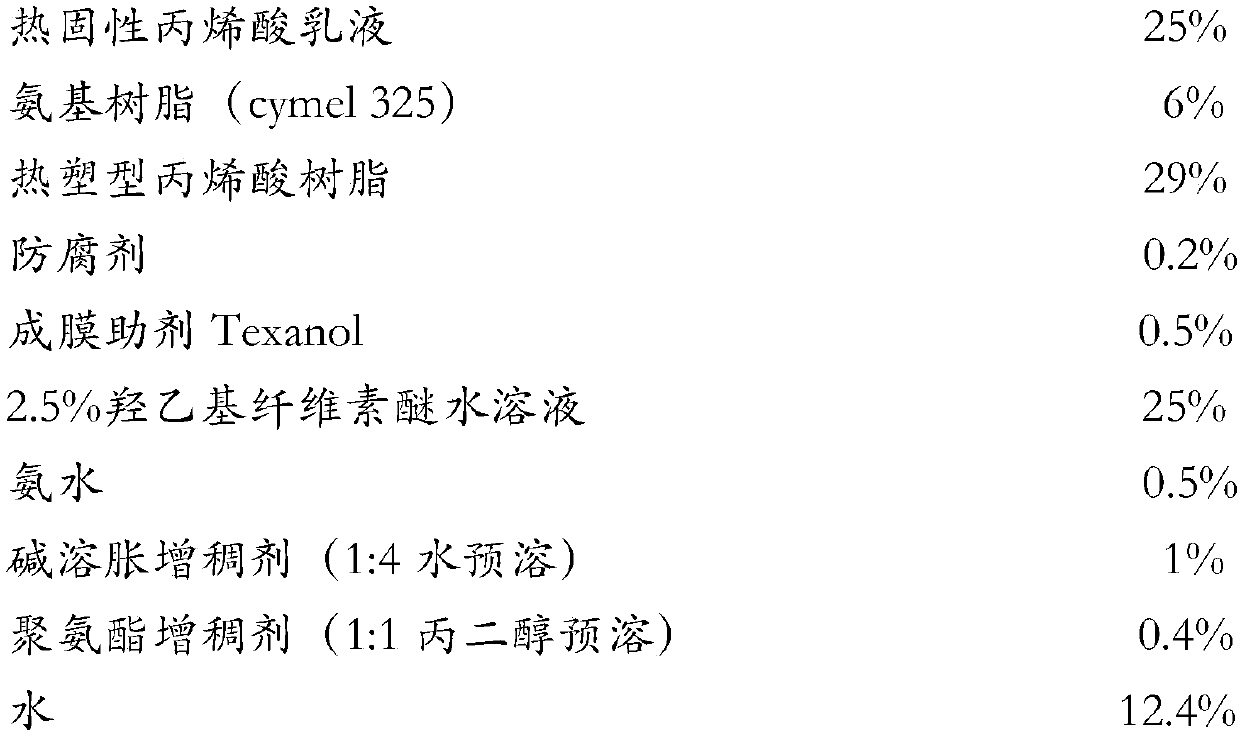

[0057] The mixed emulsion formula is:

[0058]

[0059] Put thermosetting acrylic emulsion, amino resin, and thermoplastic acrylic resin into a clean reaction kettle according to the formula, and turn on the disperser at a low speed to stir the three emulsions evenly;

[0060] Gradually turn on the high-speed (about 500-700 rpm) of the disperser, add preservatives, 2.5% hydroxyethyl cellulose aqueous solution (the preparation method of this aqueous solution is: slowly add the hydroxyethyl cellulose in the formula water under a high-speed dispersion environment) Base cellulose ether powder, and disperse at a high speed to form an aqueous solution with a concentration of 2.5%. There should be no cellulose agglomeration in the aqueous solution to ensure its uniform state. If necessary, a PH regulator can be added to accelerate the dissolution process) and fully dispersed evenly ;Reduce the speed of the disperser, slowly add the film-forming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com