Efficient preparation method of high-strength and high-toughness degradable polyester polymer

A technology for degrading polyester and polymers, applied in the field of biodegradable materials, can solve the problems of high toughness and high strength, and achieve the effect of universality, high efficiency and practicability, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

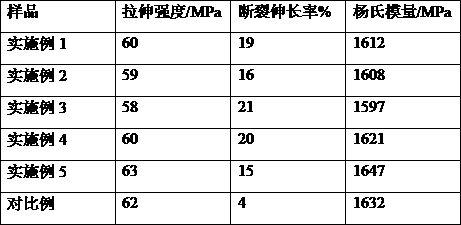

Examples

Embodiment 1

[0021] A high-efficiency preparation method for high-strength and high-toughness degradable polyester polymers is carried out according to the following steps:

[0022] Step 1: Melt 240 g of polylactic acid with a molecular weight of 200,000 in an internal mixer at 190°C, then add 1.8 g of Joncryl ADR-4370S, and blend for 15 minutes.

[0023] Step 2, the polylactic acid / Joncryl polymer obtained after the modification in step 1 is made into particles with a diameter of 1~3mm through a granulator, and then melted in a hot press under zero pressure for 5 minutes, and then melted under 5 MPa Hot pressing for 3 minutes, 15 MPa hot pressing for 2 minutes, and then cooling to 15 °C at a rate of 20 °C / min to finally obtain a polymer tensile standard test piece of about 3 mm.

[0024] In step 3, the obtained polymer samples were immediately transferred to a refrigerator at -40°C for 120 hours.

[0025] Step 4, transfer the frozen polymer sheet to an ultraviolet crosslinker for 30 hour...

Embodiment 2

[0027] A high-efficiency preparation method for high-strength and high-toughness degradable polyester polymers is carried out according to the following steps:

[0028] Step 1: Melt 240 g of polyglycolic acid with a molecular weight of 220,000 at 190°C in an internal mixer, then add 1.2 g of Joncryl ADR-4368C, and blend for 12 minutes.

[0029] Step 2, the polyglycolic acid / Joncryl polymer obtained after modification in step 1 is made into particles with a diameter of 1~3mm through a granulator, and then melted in a hot press under zero pressure for 5 minutes, and then 5 MPa Under hot pressing for 3 min, 15 MPa hot pressing for 2 min, and then cooling to 15 °C at a rate of 30 °C / min, finally obtain a polymer tensile standard test piece of about 3 mm.

[0030] In step 3, the obtained polymer samples were immediately transferred to a refrigerator at -25°C for 48 hours.

[0031] Step 4, transfer the frozen polymer sheet to an X-ray irradiator for 10 hours of radiation.

Embodiment 3

[0033] A high-efficiency preparation method for high-strength and high-toughness degradable polyester polymers is carried out according to the following steps:

[0034]Step 1: Melt 240 g of poly(lactic-co-glycolic acid) copolymer with a molecular weight of about 200,000 at 195°C in an internal mixer, and then add 2 g of poly(2-ethyl-2-oxo) with a molecular weight of 5,000 oxazoline), and the blending reaction was 17 min.

[0035] Step 2, the poly(lactic-co-glycolic acid) copolymer / poly(2-ethyl-2-oxazoline) polymer obtained after modification in step 1 is made into granules with a diameter of 1~3mm through a granulator, and then heated and pressed In the machine, melt at zero pressure for 5 minutes, then hot press at 5 MPa for 3 minutes, hot press at 15 MPa for 2 minutes, then cool to 15 °C at a rate of 30 °C / min, and finally obtain a polymer tensile standard test piece of about 3 mm Sample.

[0036] In step 3, the obtained polymer samples were immediately transferred to a re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com