An efficient heat insulating material for a dam concrete surface and a preparing method thereof

A technology for concrete surface and thermal insulation materials, applied in fireproof coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problem of good heat resistance and durability, poor flame retardancy, unsatisfactory dam thermal insulation effect, deformation Poor adaptability and other problems, to achieve the effect of excellent sealing and overall performance, excellent thermal insulation, and strong deformation adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

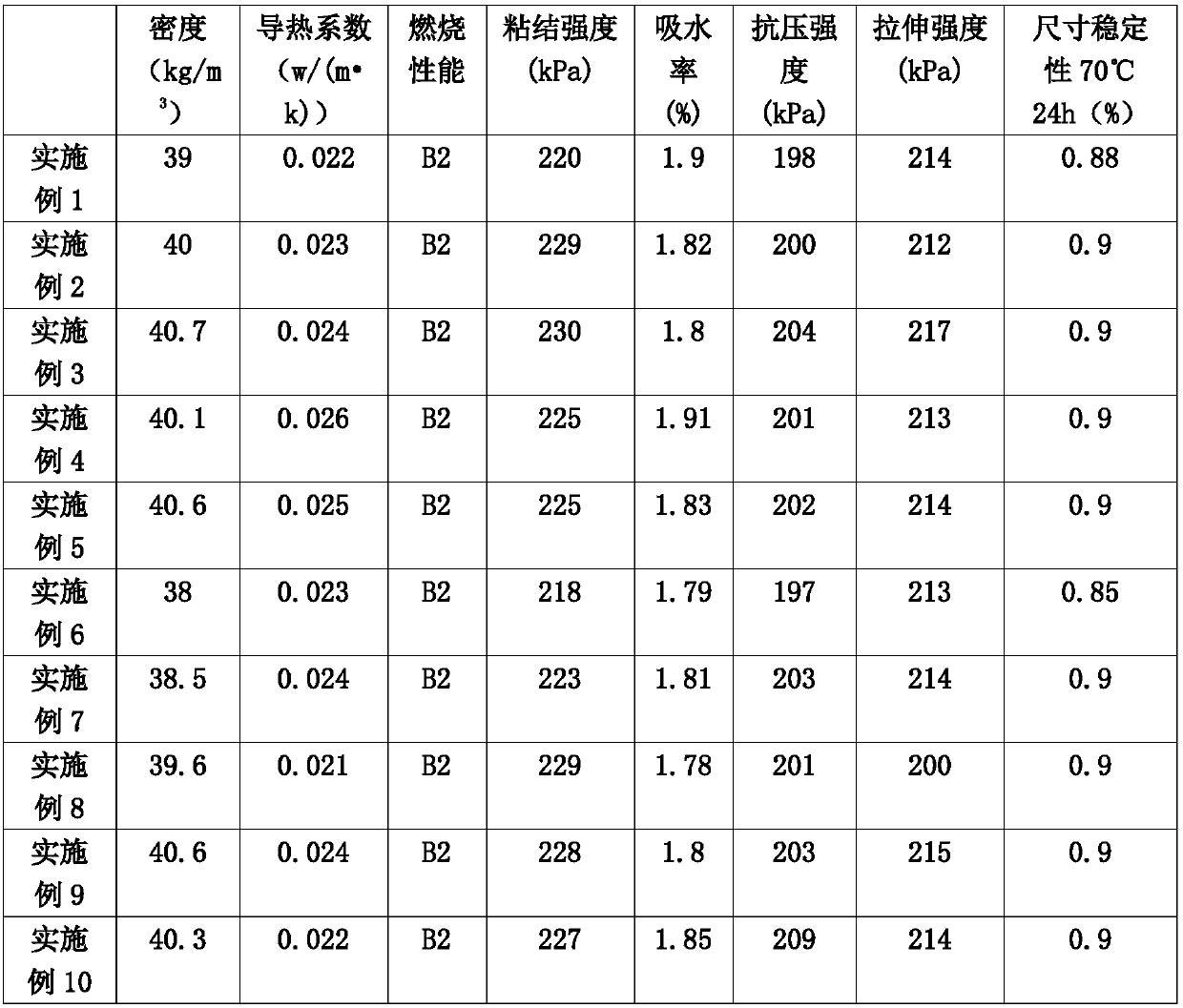

Examples

Embodiment 1

[0055] A high-efficiency thermal insulation material for the surface of dam concrete, which is rigid polyurethane foam, and consists of component A and component B; the component A consists of 38 parts by weight of polyether 4110, 0.01 part by weight of EP-44, and 1 part by weight of three Ethylamine, 1 part by weight of dibutyltin oxide, 0.10 parts by weight of polyurethane rigid foam silicone oil AK-158, 7.00 parts by weight of fluorodichloroethane, 1 part by weight of deionized water, 10 parts by weight of dimethyl methylphosphonate , 1 part by weight of aluminum hydroxide; the B component is 57 parts by weight of MDI.

[0056] The method for preparing the high-efficiency thermal insulation material on the concrete surface of the dam comprises the following steps:

[0057] Step 1: Prepare component A, weigh the polyether polyol, epoxy resin, first catalyst, second catalyst, polyurethane rigid foam silicone oil AK-158, first foaming agent, second foaming agent agent, the fi...

Embodiment 2

[0062] A high-efficiency thermal insulation material for the surface of dam concrete, which is rigid polyurethane foam, and consists of component A and component B; the component A consists of 5 parts by weight of polyether 4110, 1 part by weight of EP-44, and 0.30 parts by weight of three Ethylamine, 0.35 parts by weight of dibutyltin oxide, 2.0 parts by weight of polyurethane rigid foam silicone oil AK-158, 9.00 parts by weight of HCFC-141B, 0.1 parts by weight of deionized water, 1 part by weight of dimethyl phosphonate, 0.4 parts by weight parts of aluminum hydroxide; the B component is 55 parts by weight of MDI.

[0063] Its preparation method is with embodiment 1.

Embodiment 3

[0065] A high-efficiency thermal insulation material for the concrete surface of a dam, which is rigid polyurethane foam, consists of component A and component B; the component A consists of 21 parts by weight of polyether 4110, 0.59 parts by weight of EP-44, and 0.26 parts by weight of Triethylamine, 0.43 parts by weight of dibutyltin oxide, 1.30 parts by weight of polyurethane rigid foam silicone oil AK-158, 8.64 parts by weight of HCFC-141B, 0.86 parts by weight of deionized water, 4 parts by weight of dimethyl methylphosphonate , 0.32 parts by weight of aluminum hydroxide; the B component is 56.12 parts by weight of MDI.

[0066] Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com