Preparation method of alginate lyase immobilized enzyme

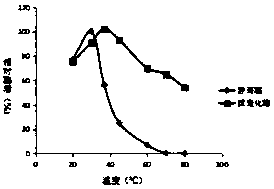

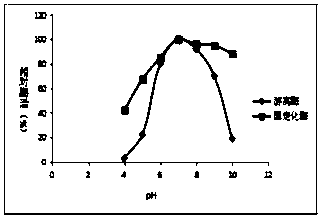

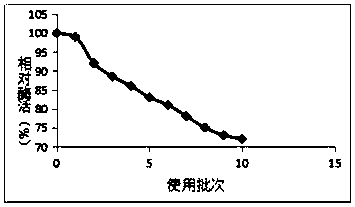

A technology of alginate lyase and immobilized enzyme, which is applied in the field of preparation of alginate lyase immobilized enzyme, can solve the problems of limited development and poor stability, and achieve good stability, low cost, and excellent acid and alkali resistance environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method for alginate lyase immobilized enzyme, specifically comprising the following steps:

[0028] (1) Chitosan and tamarind gum are mixed and ground into powder, passed through a 60-mesh sieve, soaked at room temperature for 4 hours, washed away impurities, and dried after suction filtration; the molecular weight of the chitosan is 30000-40000Da; The mass ratio of chitosan and tamarind gum is 4:1;

[0029] (2) Dissolve the chitosan-tamarind gum mixture with 3% acetic acid solution, the final concentration is 2%-5%, ultrasonically until the bubbles disappear and become a transparent gel, take the gel and add it to the coagulation solution, and harden overnight , washed with water until neutral, and stored at 4°C; the condensate consists of a mixture of 15% NaOH solution and 95% ethanol, with a volume ratio of 4:1;

[0030] (3) Take chitosan-tamarind gum pellets and place them in glutaraldehyde solution, the mass concentration of glutaraldehyde is 3%, the...

Embodiment 2

[0033] A preparation method for alginate lyase immobilized enzyme, specifically comprising the following steps:

[0034] (1) Chitosan and tamarind gum are mixed and ground into powder, passed through a 60-mesh sieve, soaked at room temperature for 4 hours, washed away impurities, and dried after suction filtration; the molecular weight of the chitosan is 30000-40000Da; The mass ratio of chitosan and tamarind gum is 3:1;

[0035] (2) Dissolve the chitosan-tamarind gum mixture with 3% acetic acid solution, the final concentration is 2%-5%, ultrasonically until the bubbles disappear and become a transparent gel, take the gel and add it to the coagulation solution, and harden overnight , washed with water until neutral, and stored at 4°C; the condensate consists of a mixture of 15% NaOH solution and 95% ethanol, with a volume ratio of 4:1;

[0036] (3) Take chitosan-tamarind gum pellets and place them in glutaraldehyde solution, the mass concentration of glutaraldehyde is 3%, the...

Embodiment 3

[0039] A preparation method for alginate lyase immobilized enzyme, specifically comprising the following steps:

[0040] (1) Chitosan and tamarind gum are mixed and ground into powder, passed through a 60-mesh sieve, soaked at room temperature for 4 hours, washed away impurities, and dried after suction filtration; the molecular weight of the chitosan is 30000-40000Da; The mass ratio of chitosan and tamarind gum is 5:1;

[0041] (2) Dissolve the chitosan-tamarind gum mixture with 3% acetic acid solution, the final concentration is 2%-5%, ultrasonically until the bubbles disappear and become a transparent gel, take the gel and add it to the coagulation solution, and harden overnight , washed with water until neutral, and stored at 4°C; the condensate consists of a mixture of 15% NaOH solution and 95% ethanol, with a volume ratio of 4:1;

[0042] (3) Take chitosan-tamarind gum pellets and place them in glutaraldehyde solution, the mass concentration of glutaraldehyde is 3%, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com