High-quality alloy tool steel 42 CrMo4 quenched and tempered steel plate and production method thereof

A technology of alloy tool steel and quenched and tempered steel plate, which is applied in the field of high-quality alloy tool steel production, and can solve problems such as increasing customer costs, unable to meet demand as soon as possible, and inconvenient customers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

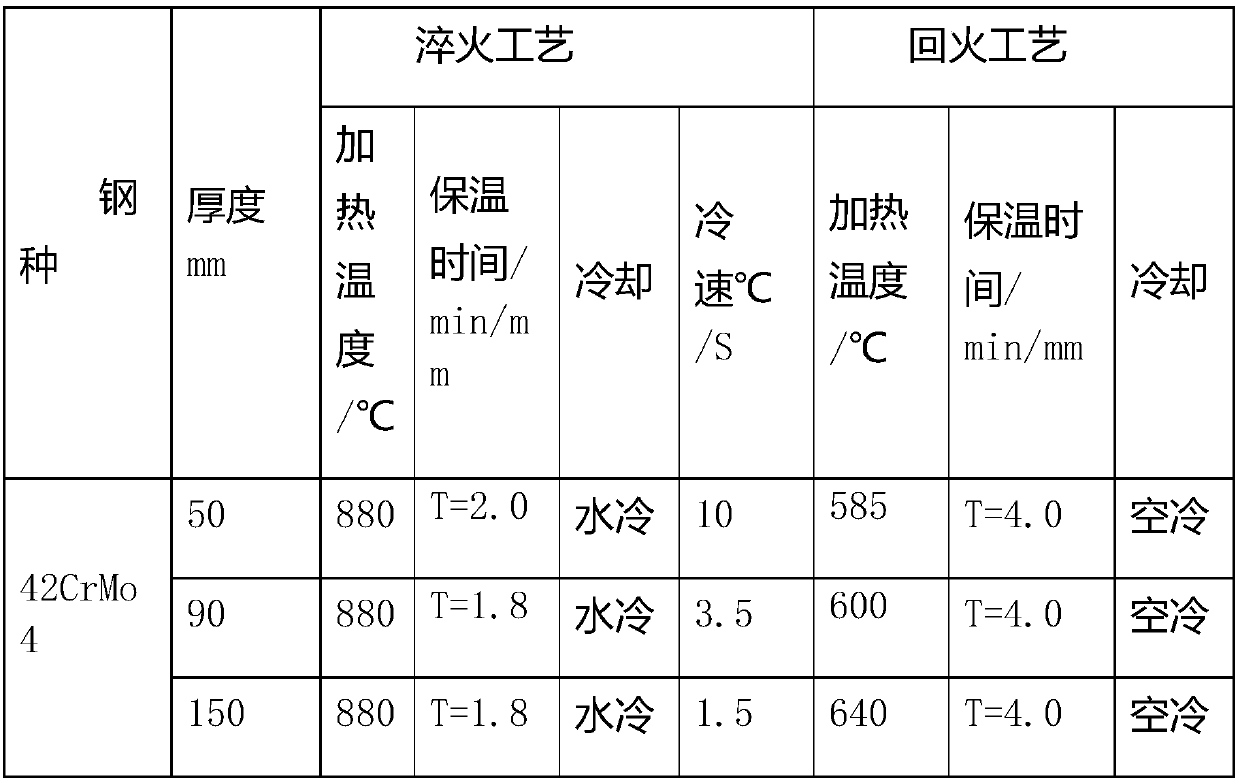

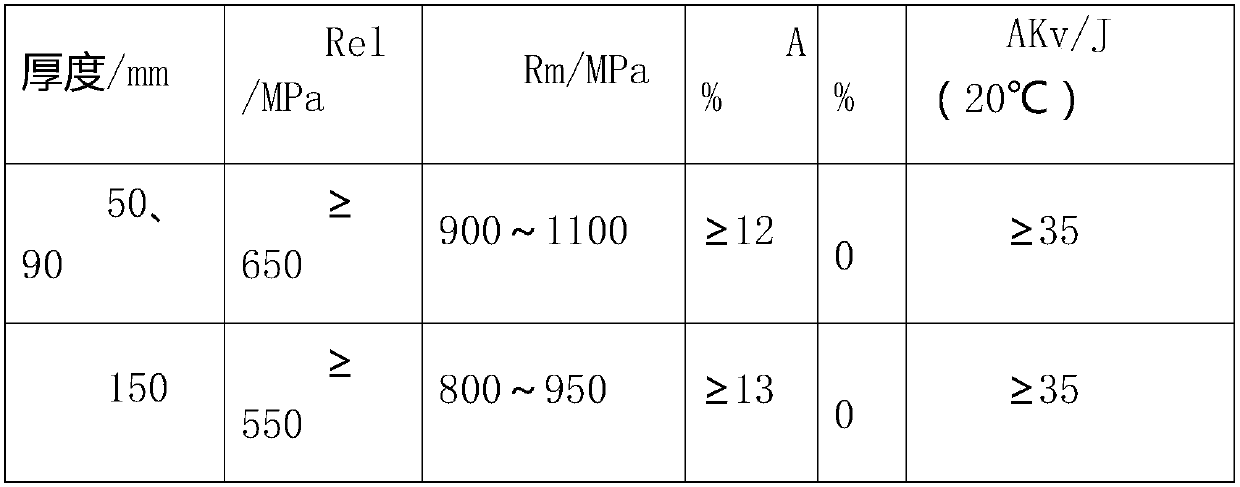

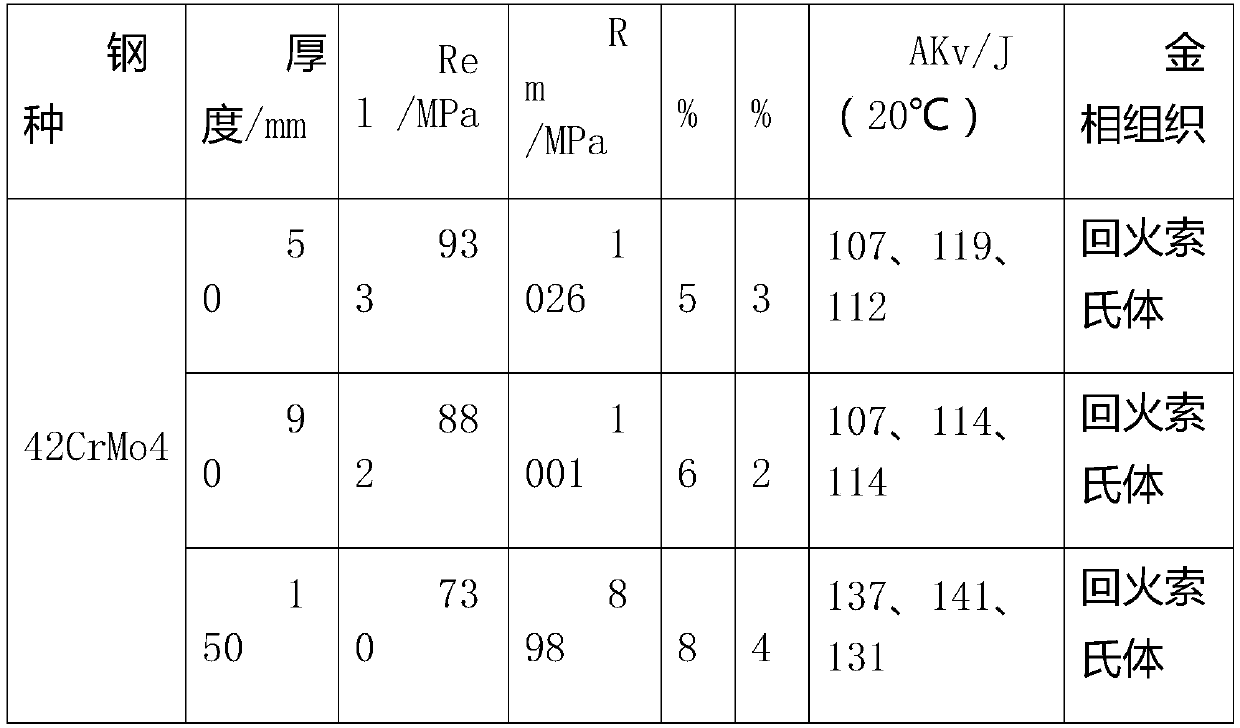

[0015] The technical features of the present invention will be further described below in conjunction with the embodiments.

[0016] The embodiment of the present invention is to produce a kind of high-quality alloy tool steel 42CrMo4 quenched and tempered steel plate, its thickness is 50-150mm, comprises the chemical composition of following mass percentage: 0.39%≤C≤0.25%, 0.2%≤Si≤0.30%, 0.75% %≤Mn≤0.85%, P≤0.018%, S≤0.005%, 0.95%≤Cr≤1.05%, 0.18%≤Mo≤0.25%, 0.02%≤Als≤0.04%, 0.741≤CEV≤0.004%, others are Fe and trace elements: Ti≤0.01%, B≤0.0.00075%, As≤0.012%, N≤0.008%, Cu≤0.04%, where CEV=C+Mn / 6+(Mo+V+Cr) / 5 +(Ni+Cu) / 15.

[0017] In the above-mentioned technical scheme adopted by the present invention, C, Si, Mn are the key elements to improve the strength of the steel plate, and the C content determines the process system of smelting, heating, rolling, and heat treatment of 42CrMo4, and the high-content C element of this steel type is also The carbon equivalent is increased,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com