Three-axis vibration test table and control method

A test bench and shaft vibration technology, which is applied in vibration testing, machine/structural component testing, measuring devices, etc., can solve problems such as time-consuming, cumbersome operation, and inability to truly reflect the anti-vibration performance of products, so as to achieve expanded application and expansion strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

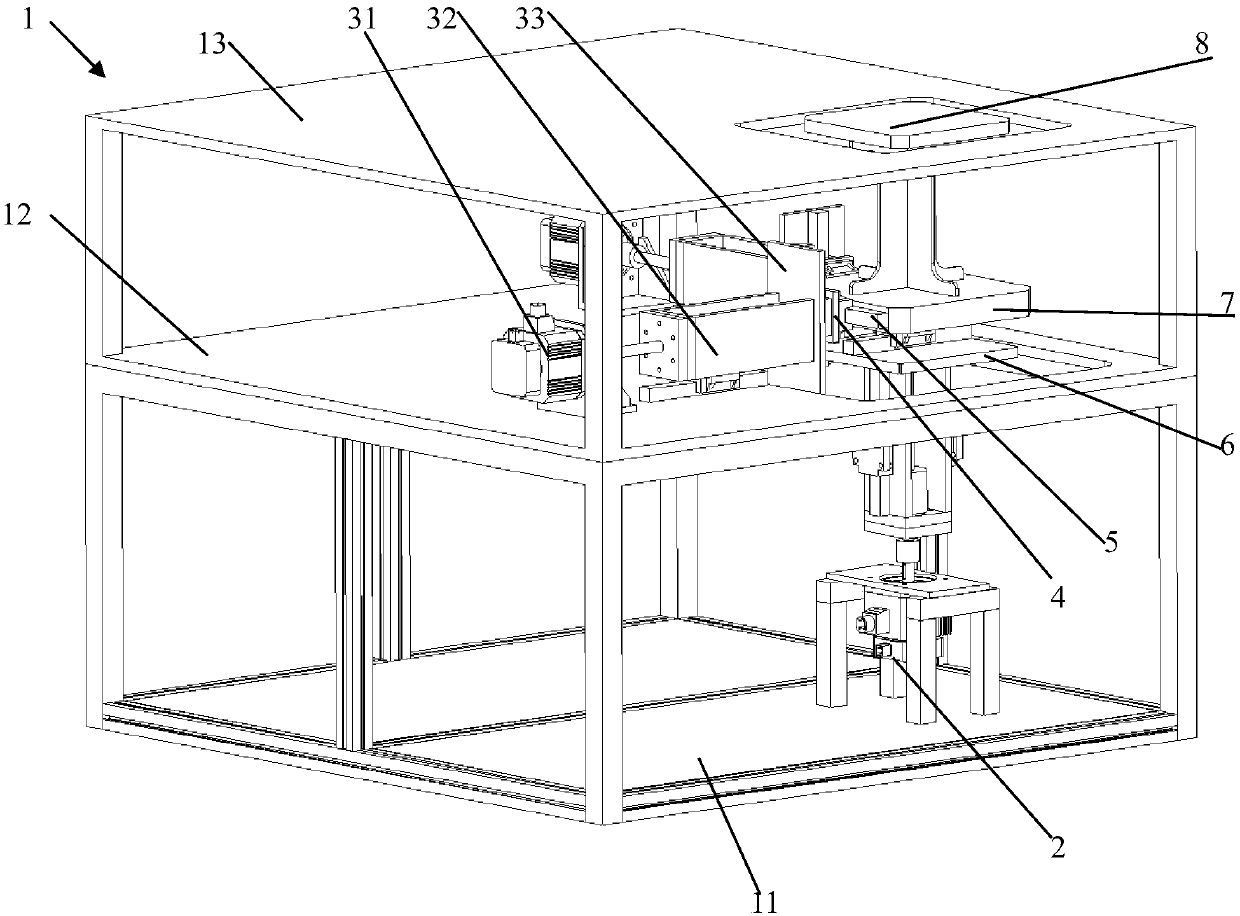

[0025] A three-axis vibration test bench of the present invention includes a frame body 1, a bottom carrier plate 6 driven to move up and down, and a bottom carrier plate 6 arranged above the bottom carrier plate and driven to translate relative to the bottom carrier plate. The top carrier plate 7, the test platform 8 fixedly arranged on the top carrier plate, and the cross guide mechanism, the cross guide mechanism includes correspondingly arranged on the two groups of vertical and spaced linear guides 5 , an intermediate plate 4 located between two sets of linear guides, and guides respectively provided on both sides of the intermediate plate and correspondingly matched with the linear guides, the bottom carrier plate and A cross guide mechanism is arranged between the top carriers, and the set of linear guides 5 are respectively fixed on adjacent surfaces of the bottom carrier and the top carrier. The middle board is located between the bottom carrier board and the top carr...

Embodiment 2

[0030] On the basis of the above-mentioned embodiments, the drive mechanism for driving the top carrier plate to move relative to the bottom carrier plate includes a horizontal drive mechanism and a longitudinal drive mechanism, which respectively include a translational drive motor 31, and the reciprocating linear motion is driven by the translational drive motor. The slide plate 33, the cross guide mechanism is arranged between the slide plate and the top carrier plate. One set of linear guides of the cross guide mechanism is correspondingly arranged on the horizontal side of the top carrier plate, and another set of corresponding linear guides is vertically arranged on the slide plate 33. The horizontal drive mechanism and the longitudinal drive structure The linear guides are located on two adjacent sides on the top carrier side. A cross guide mechanism is set between the slide plate and the top carrier plate, which can satisfy the vertical and horizontal linear motions of...

Embodiment 3

[0033] On the basis of the above embodiments, the driving mechanism for driving the bottom carrier to move up and down includes a lifting drive motor 2 fixedly arranged on the bottom platform of the frame, and the lifting frame that moves up and down is driven by the lifting drive motor. , the bottom carrier plate is fixed on the lifting frame, a guide rail slider structure is arranged between the lifting frame and the middle platen, and the lifting drive motor drives the lifting frame through a screw nut mechanism Reciprocating up and down motion. At the same time, it also includes a controller controllably connected with the lifting drive motor and the translation drive motor. Further, an exciter controlled by the above-mentioned controller can also be provided, the exciter is arranged on the top carrier plate, and is arranged between the top carrier plate and the test piece to provide low-frequency or high-frequency vibration, so that it can be stacked Four types of vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com