Vector magnetic field sensor based on side-polished fiber surface plasmon resonance and manufacturing and detection method thereof

A surface plasmon and vector magnetic field technology, which is applied in the use of magneto-optical equipment for magnetic field measurement, magnetic field size/direction, single-device manufacturing, etc., to achieve the effects of high sensitivity and linearity, improved sensitivity, and high-sensitivity sensing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

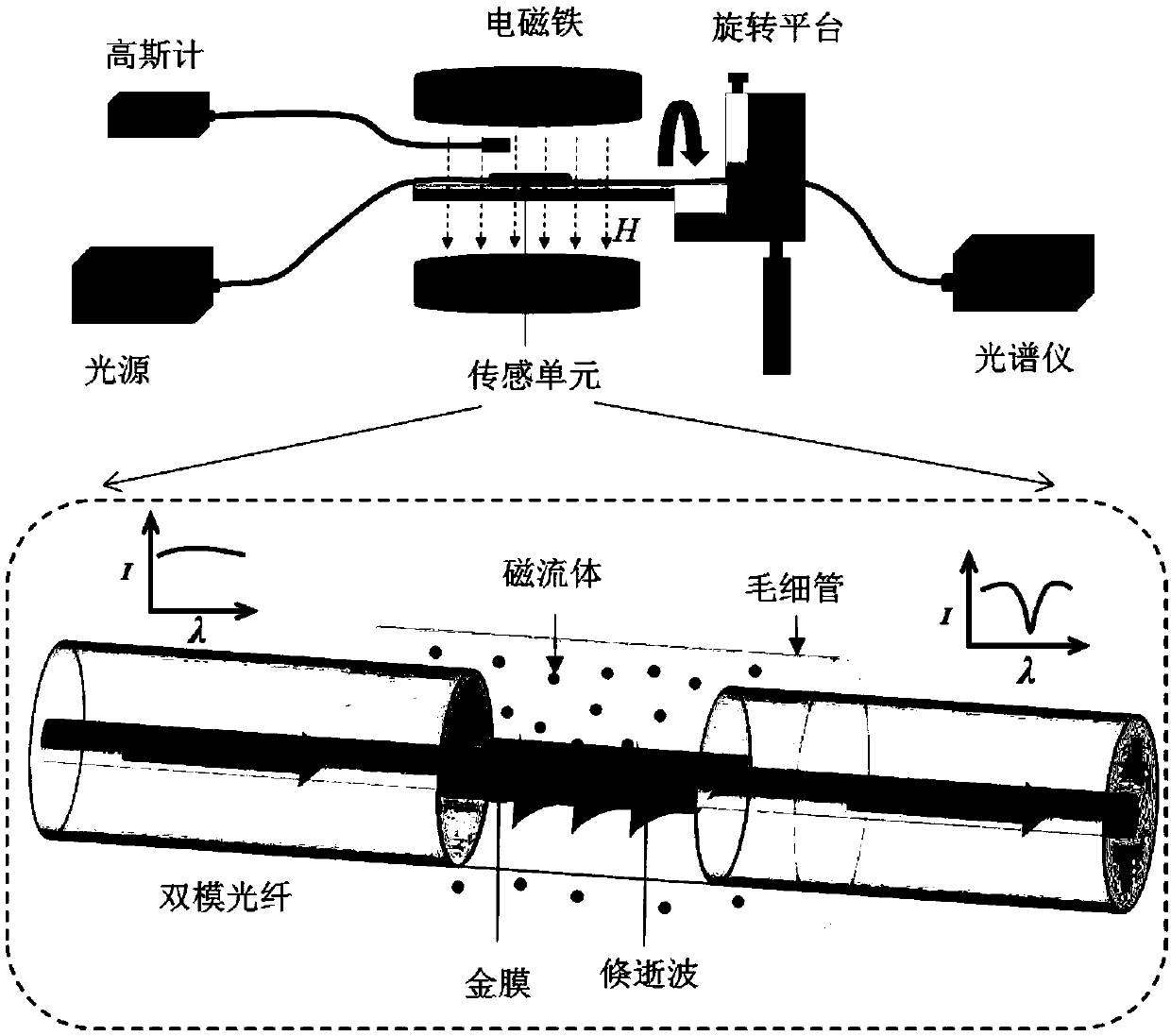

[0031] A vector magnetic field sensor based on surface plasmon resonance of a side-polished optical fiber, comprising a side-polished optical fiber, a metal film disposed on a polished area, a magnetic fluid, a light source, and a spectrometer for detecting a transmission spectrum, the polished optical fiber It is manufactured by polishing off the cladding on one side of the optical fiber; the polished optical fiber is provided with a glass capillary and optical ultraviolet glue, and the magnetic fluid is sealed and wrapped around the polished optical fiber through the glass capillary and optical ultraviolet glue.

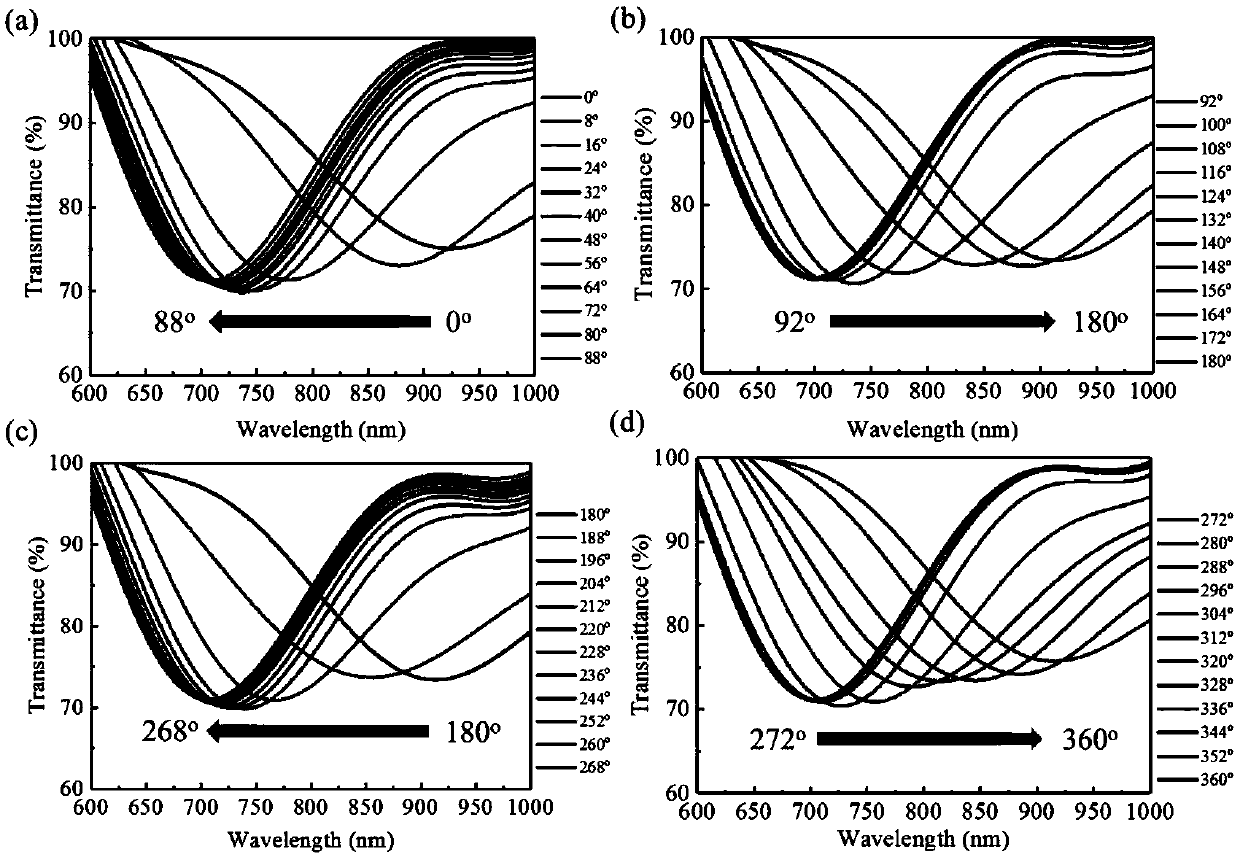

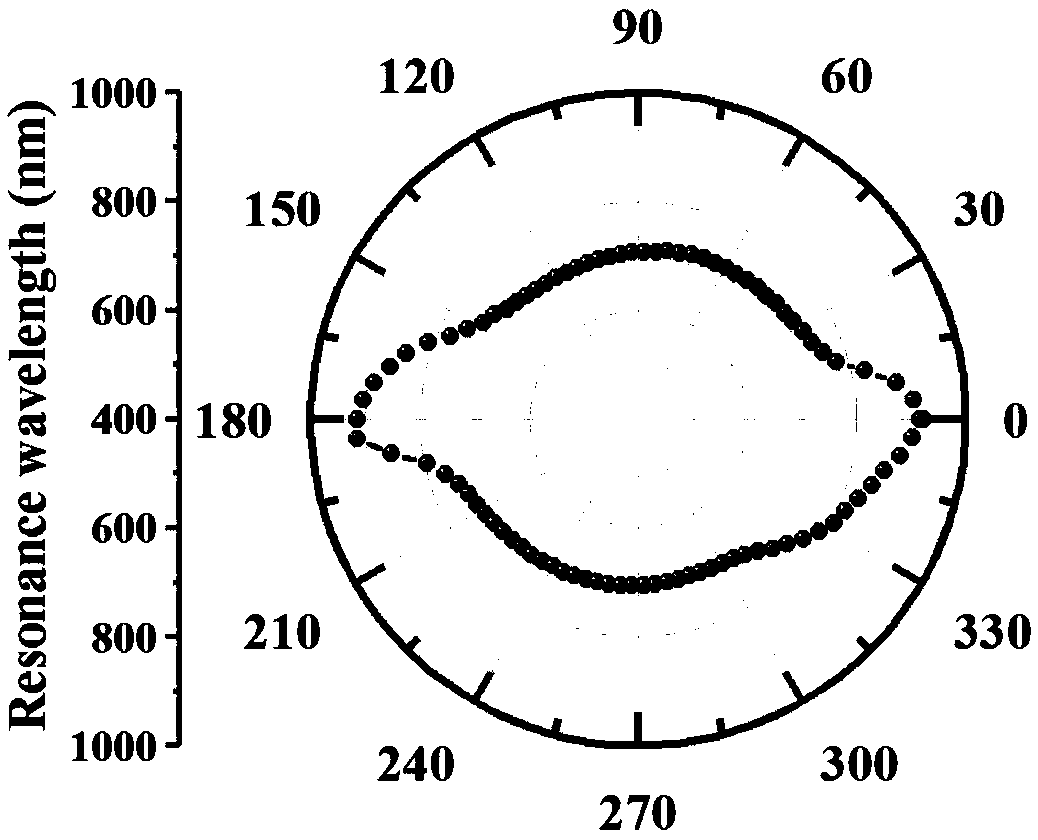

[0032] Its working principle: under the action of a magnetic field, when the incident light is parallel to the direction of the magnetic field, the nanoparticles in the magnetic fluid gather into high-density nanogroups; when the incident light is perpendicular to the direction of the magnetic field, the nanoparticles in the magnetic fluid gather into low-density nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com