Welding device with semi-closed space

A welding device and semi-closed technology, applied in auxiliary devices, welding equipment, coatings, etc., can solve the problems of volatile matter volatilization, strong odor, affecting the health and safety of operators, etc., and achieve the effect of protecting health and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

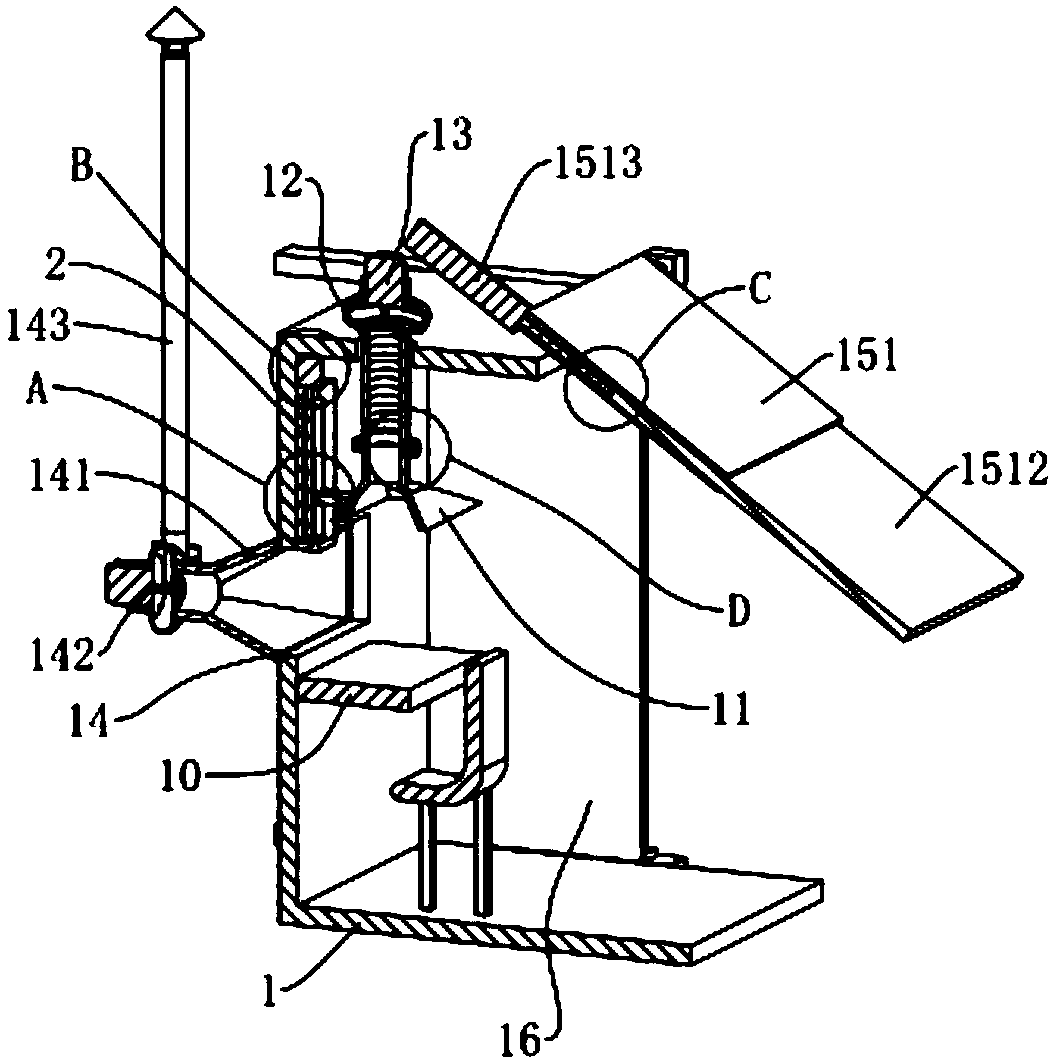

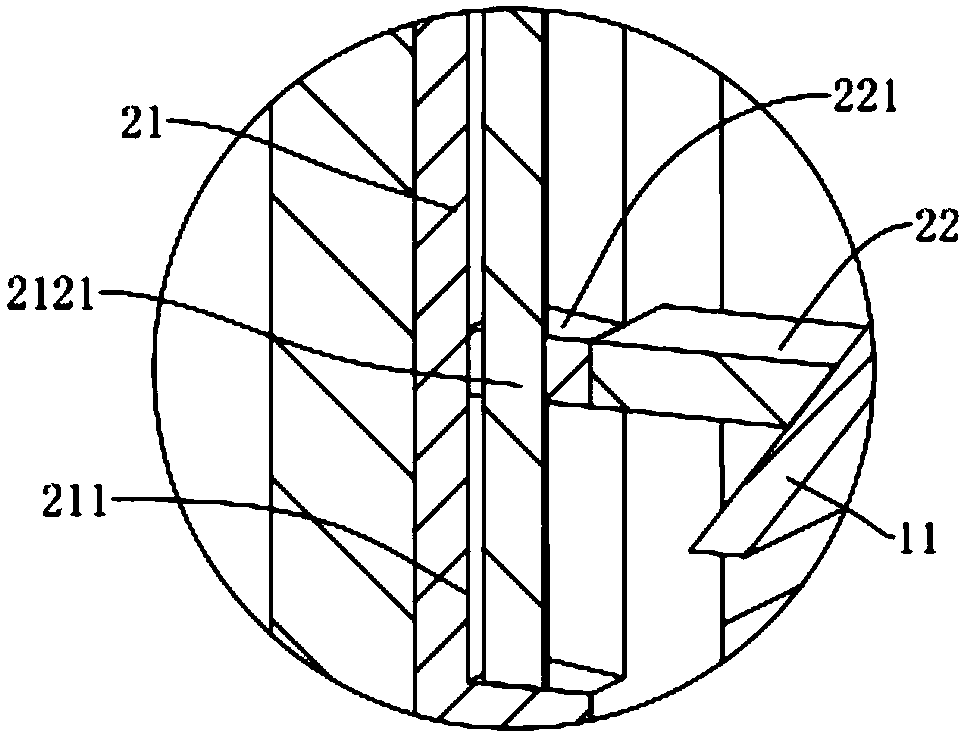

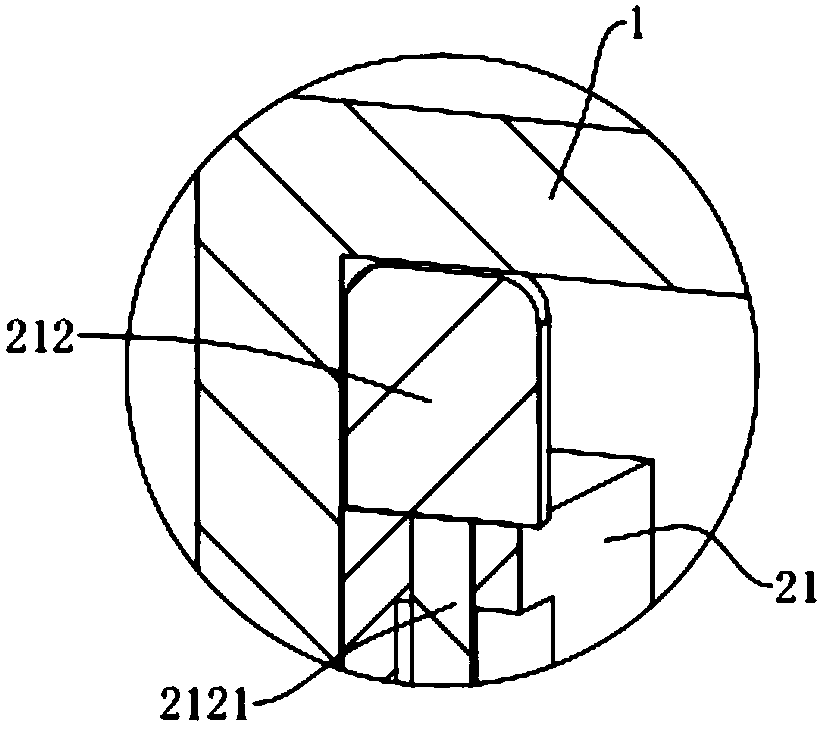

[0045] refer to figure 1 and Figure 5 , a welding device in a semi-enclosed space, comprising a welding room 1, wherein the welding room 1 is a 匚-shaped stainless steel building, in order to facilitate soldering in the welding room 1, a welding platform for soldering is fixed in the welding room 1 10. At the same time, a seat can also be configured in the welding room 1, and the operator can sit on the seat and perform soldering on the top of the welding platform 10; because in the soldering process, the solder used in the soldering contains clamps and auxiliary Flux, harmful substances will volatilize when the welding rod melts. In order not to affect the health of the welding operator, a first drainage cover 11 is slid and connected in the vertical direction above the welding platform 10 inside the welding room 1. The first drainage cover 11 is set in a form that can be adjusted up and down so that the area and range of air absorption can be adjusted, and at the same time,...

Embodiment 2

[0055] The difference from Example 1 is that the surface of the welding platform 10 is coated with an anti-fouling coating. Since the soldering is performed on the welding platform 10, it is inevitable that solder will fall on the welding platform 10 during soldering. In order to prevent the solder from adhering to the welding platform 10 and it is difficult to clean, a layer of antifouling coating is coated on the surface of the welding platform 10, so a method for preparing an antifouling coating is provided, which has the advantages of short preparation process and simple preparation. Advantages, wherein the preparation method of the antifouling coating on the surface of the welding platform 10 is as follows:

[0056] Take the following components by weight for later use: 42 parts of methyl methacrylate, 43 parts of polyethylene, 35 parts of polypropylene, 25 parts of fatty alcohol polyoxyethylene ether, 21 parts of alkylphenol polyoxyethylene ether, sodium acrylate 17 part...

Embodiment 3

[0062] The difference from Example 2 is the preparation of the antifouling coating on the surface of the welding platform 10, wherein the preparation method of the antifouling coating is as follows:

[0063] Take the following components by weight for later use: 43 parts of methyl methacrylate, 44 parts of polyethylene, 36 parts of polypropylene, 26 parts of fatty alcohol polyoxyethylene ether, 21 parts of alkylphenol polyoxyethylene ether, sodium acrylate 17 parts, 11 parts of methylisothiazolinone;

[0064] S1. Preparation of antifouling coating pre-preparation solution: mix methyl methacrylate, polyethylene and polypropylene evenly and add to the reaction kettle, heat the temperature in the reaction kettle to 185°C and keep it warm for 20 minutes to obtain an antifouling coating pre-preparation solution;

[0065] S2. Preparation of antifouling coating solution: After cooling the antifouling coating pre-preparation solution obtained in S1 to 85°C, add fatty alcohol polyoxyeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com