Ultra-thin ceramic fingerprint piece grinding technology

A grinding process and ceramic technology, applied in the field of ultra-thin ceramic fingerprint chip grinding equipment and its grinding process, can solve problems such as poor orange peel, broken products, uneven surface, etc., to avoid poor orange peel and scratches, and increase pressure and rotating speed, the effect of product surface uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

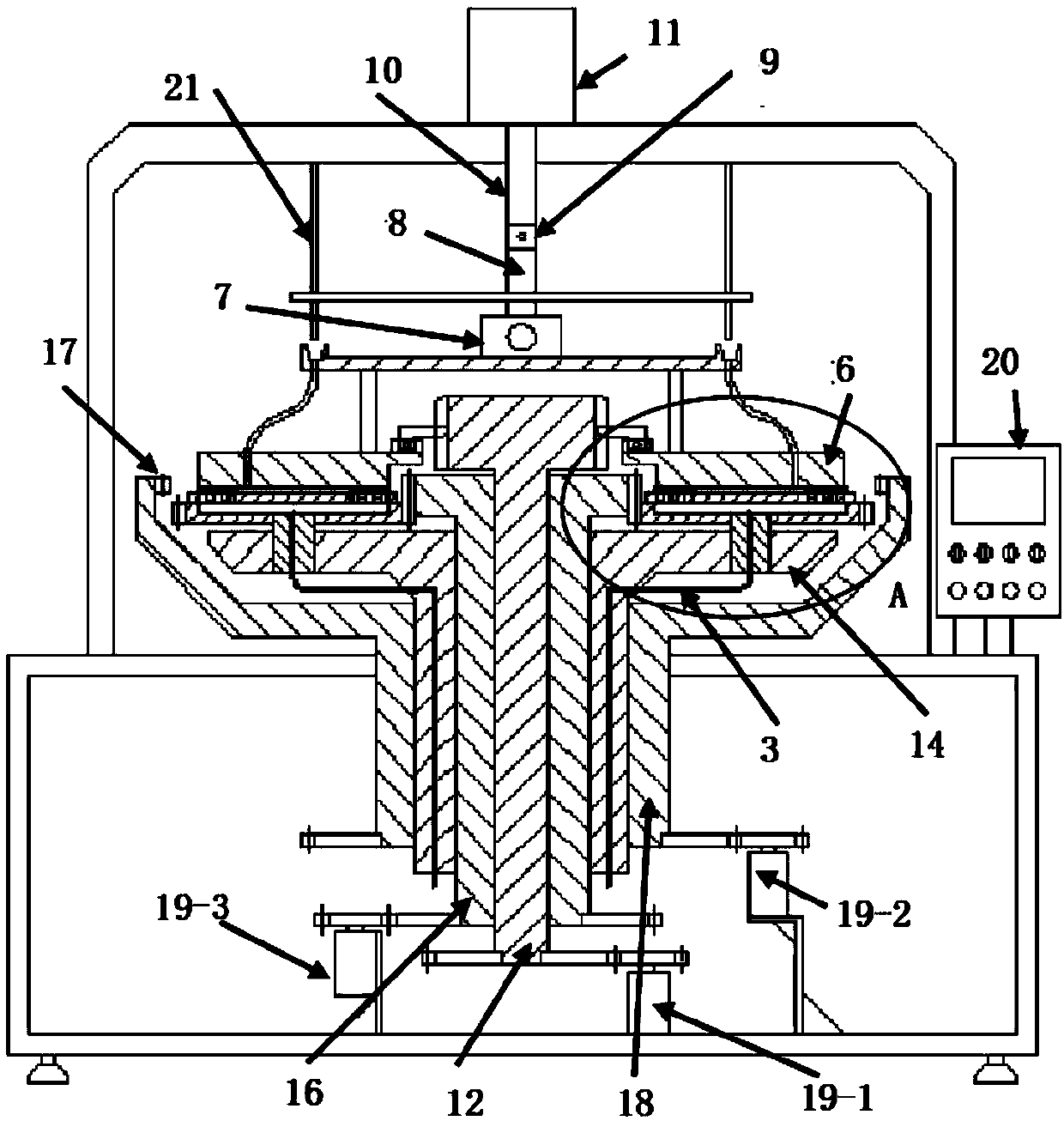

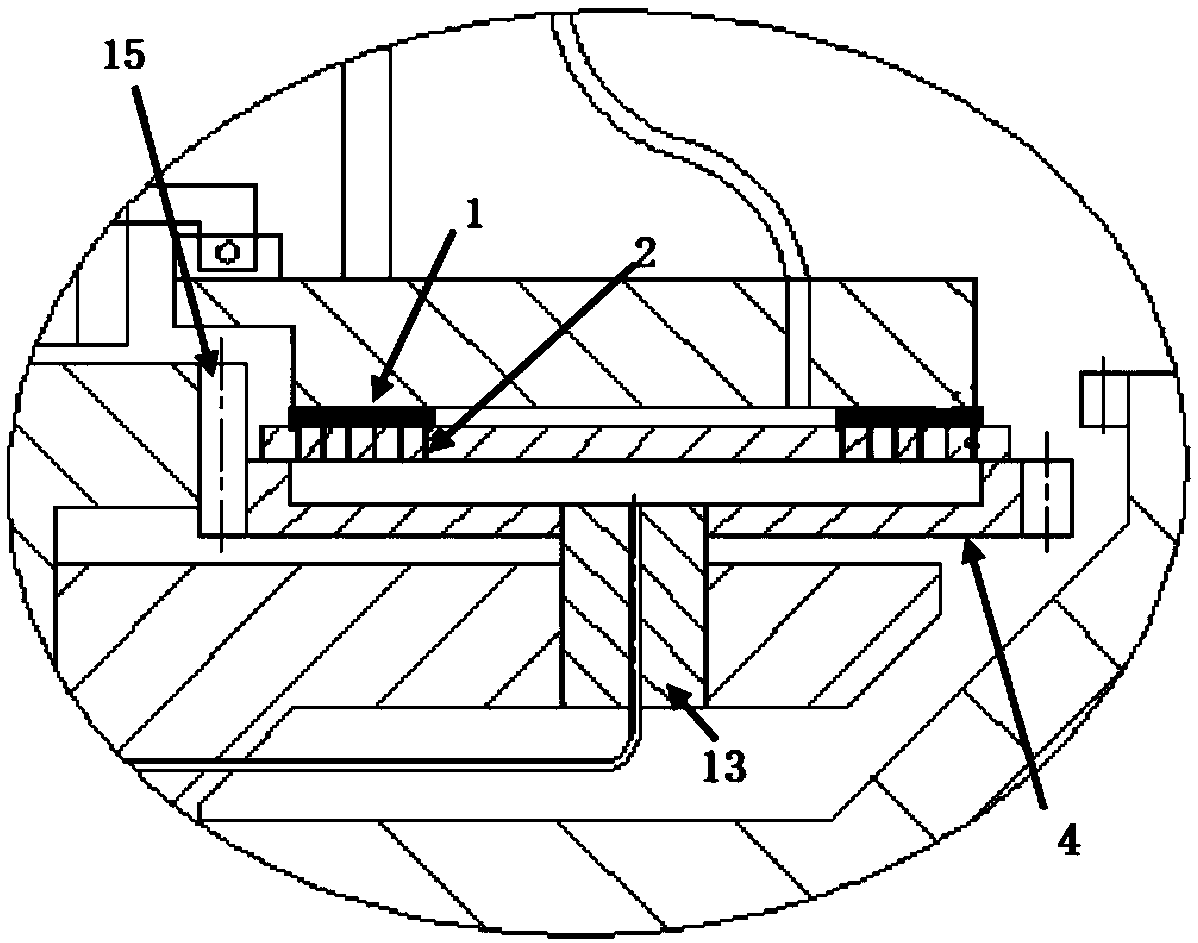

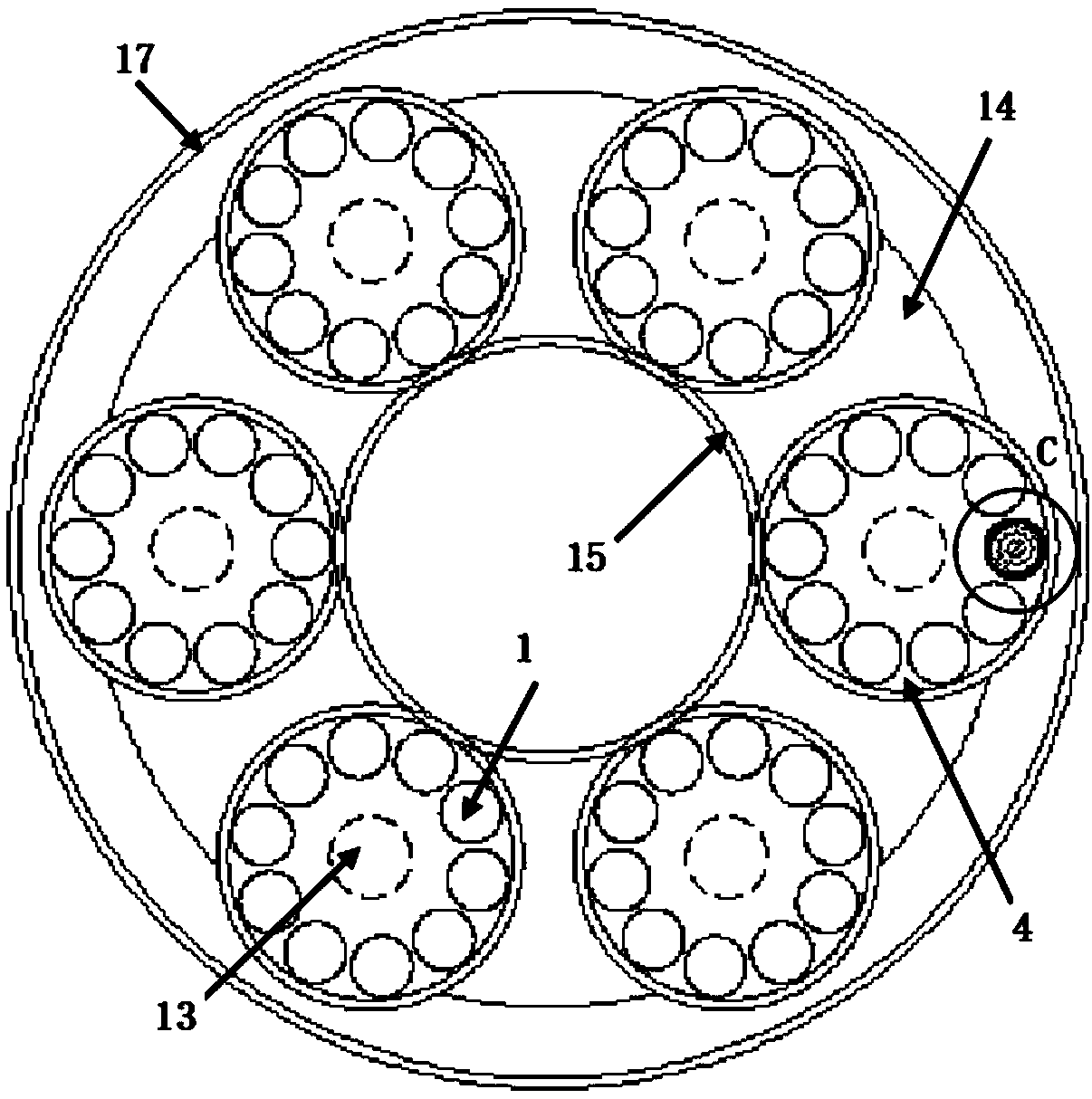

Method used

Image

Examples

Embodiment 1

[0053] Process 180 mobile phone fingerprint cover blanks with a diameter of 50mm and a thickness of 0.3mm into finished products with a thickness of 0.05mm. The coarse grinding medium is a mixed solution of 1kg of B4C with a particle size of W9 and polycrystalline diamond powder mixture and 30kg of water; the fine grinding medium is a mixed solution of 4kg of silica sol with a particle size of 120nm and 24kg of water.

[0054] Processing parameters:

[0055]

[0056]

[0057]

[0058] The first pass rate of the product obtained according to the process of this embodiment is 98.3%, and the surface roughness is 2.9nm.

Embodiment 2

[0059] Embodiment 2: 180 cell phone fingerprint cover blanks with a diameter of 50 mm and a thickness of 0.3 mm were processed into a finished product with a thickness of 0.05 mm. The coarse grinding medium is a mixed solution of 2kg of B4C with a particle size of W5 and a mixture of polycrystalline diamond microparticles and 30kg of water; the fine grinding medium is a mixed solution of 5kg of silica sol with a particle size of 50nm and 20kg of water.

[0060] Processing parameters:

[0061]

[0062]

[0063] The first pass rate of the product obtained according to the process of this embodiment is 99.4%, and the surface roughness is 2.1 nm.

Embodiment 3

[0064] Embodiment 3: 180 cell phone fingerprint cover blanks with a diameter of 50 mm and a thickness of 0.3 mm were processed into a finished product with a thickness of 0.05 mm. The grinding (coarse grinding) medium is a mixed solution of 3kg of B4C with a particle size of W7 and a mixture of polycrystalline diamond microparticles and 15kg of water; the polishing (finishing) medium is a mixed solution of 7kg of silica sol with a particle size of 80nm and 21kg of water.

[0065] Processing parameters:

[0066]

[0067]

[0068] The first pass rate of the product obtained according to the process of this embodiment is 98.8%, and the surface roughness is 2.4nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com