Full-automatic wood pallet production device

A technology for production equipment and wooden pallets, which is applied in the direction of wood processing equipment, U-shaped nail tools, nailing tools, etc., can solve the problems of large area occupied by the overall equipment, increased production costs, damage to the nozzle of the nail gun, etc., to achieve The effect of less physical exertion of workers, prolonging the service life and reducing the vibration of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

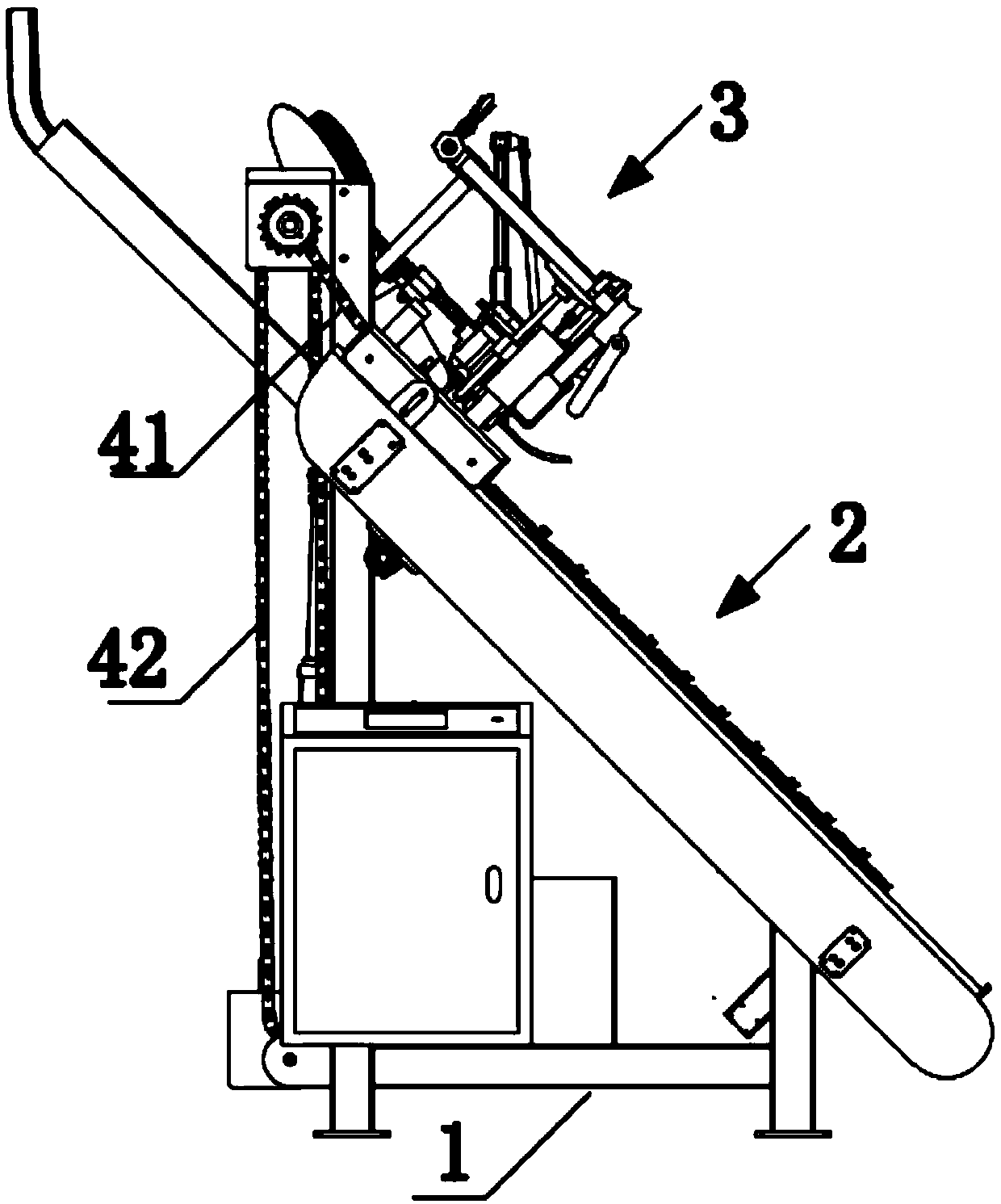

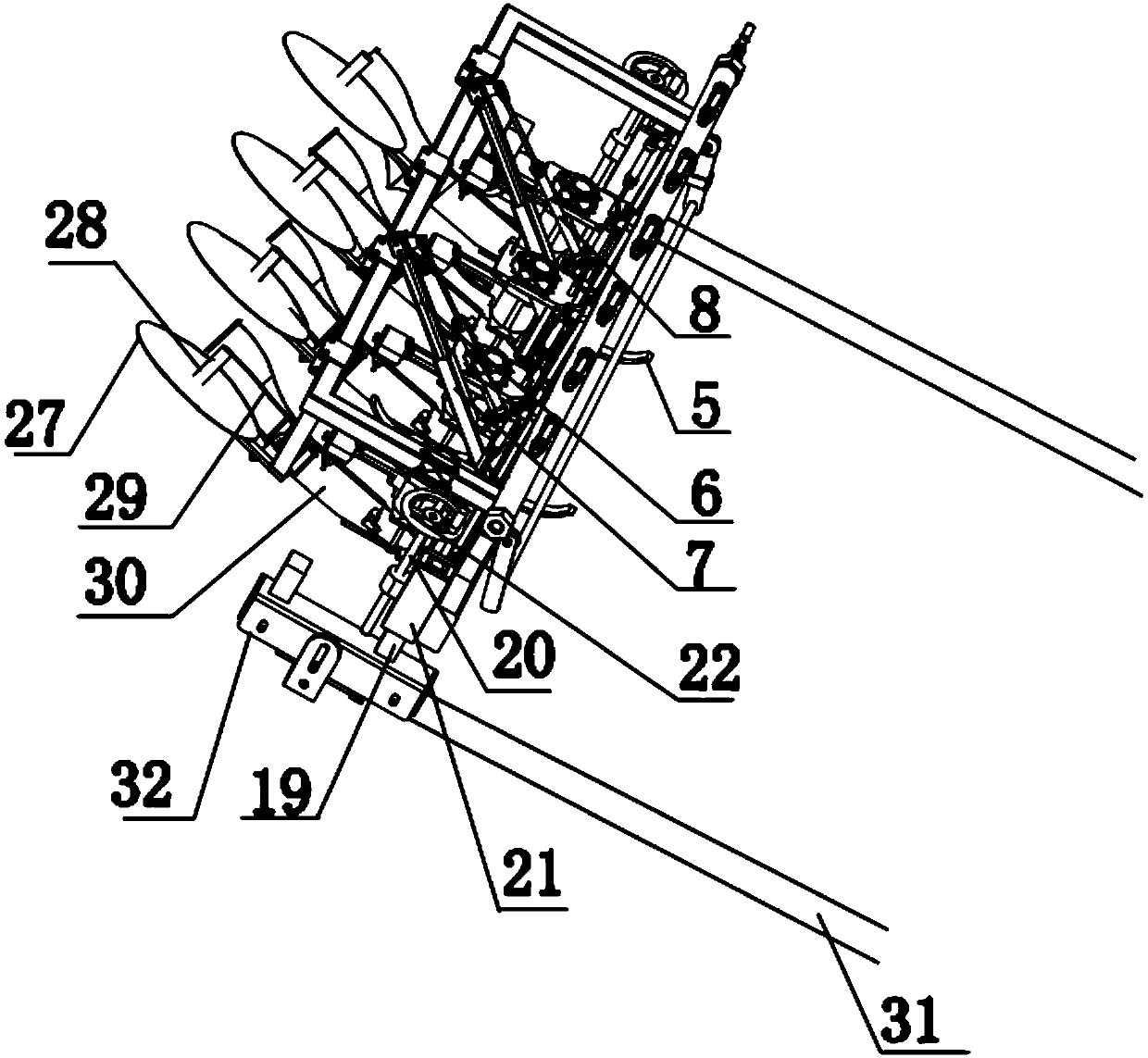

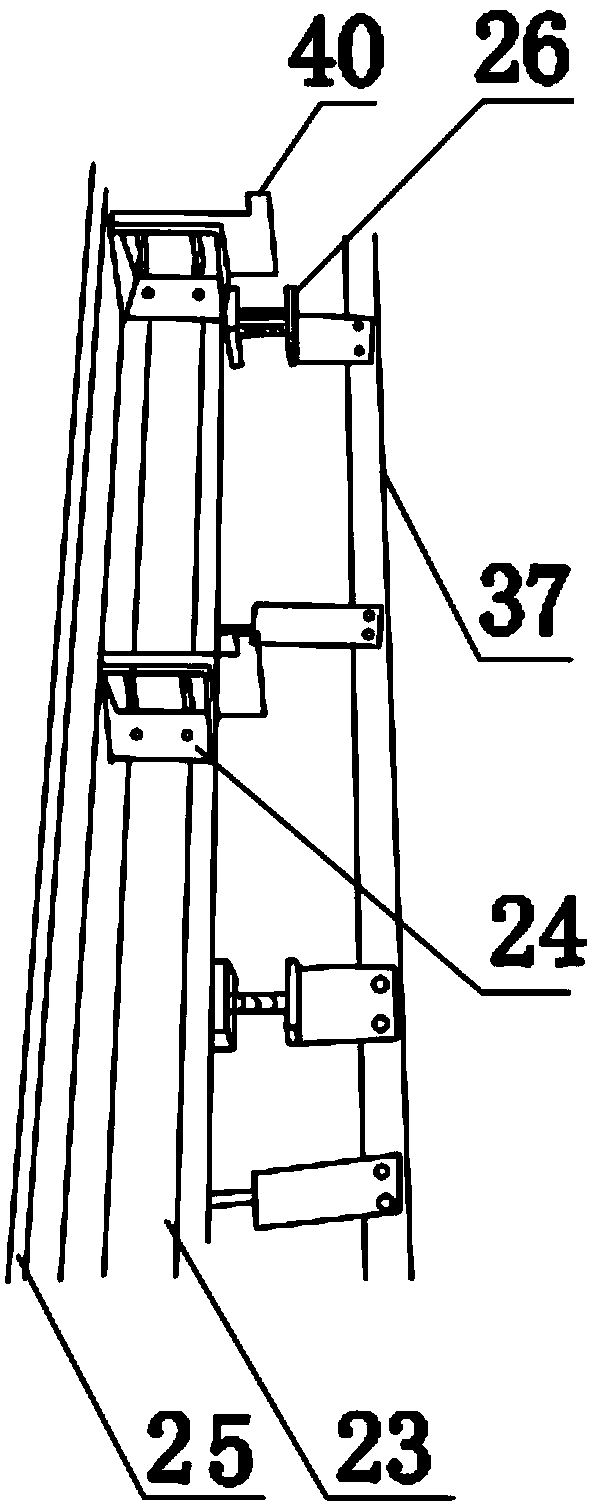

[0026] Such as figure 1 , 2, 3, 4, 5, 6, 7, and 8, a fully automatic wooden pallet production equipment includes a base 1, and the base 1 is provided with a nailing workbench 2 for laying planks and wooden piers. The nailing workbench 2 is provided with a nailing frame 3 reciprocating along the length direction of the nailing workbench, and the nailing frame is provided with a nailing gun 4 for nailing wooden piers and planks, and for nailing The first pressing and leveling of the wooden board is on the pressing device on the nailing workbench. The nailing gun can be set as a pneumatic nailing gun, and it is used to press and level the wooden board for the second time on the nailing workbench and prevent the gun nozzle of the nailing gun Nail protection mechanism against damage from contact with wood boards.

[0027] The pressing device in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com