A kind of composite stone flexible sheet and its preparation method

A flexible sheet, stone technology, applied in the field of composite stone flexible sheet, can solve problems such as unfavorable drying, long drying cycle, uncontrollable quality, etc., to improve aesthetics and service life, natural stone imitation effect Realistic, good imitation stone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

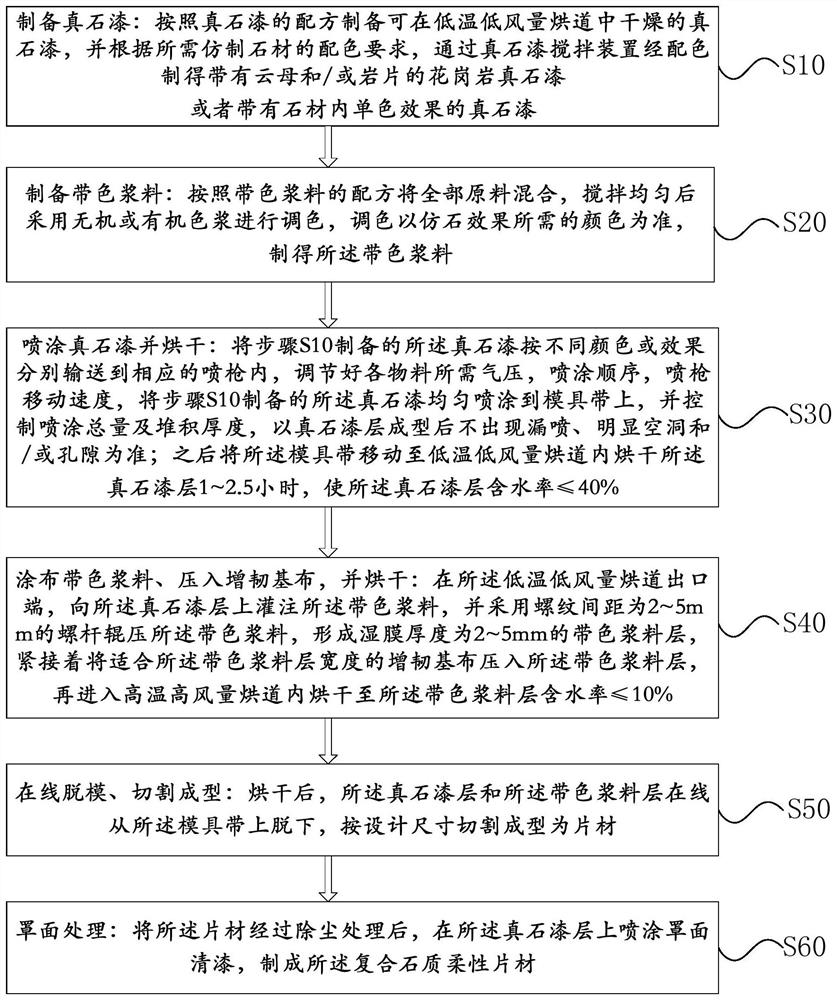

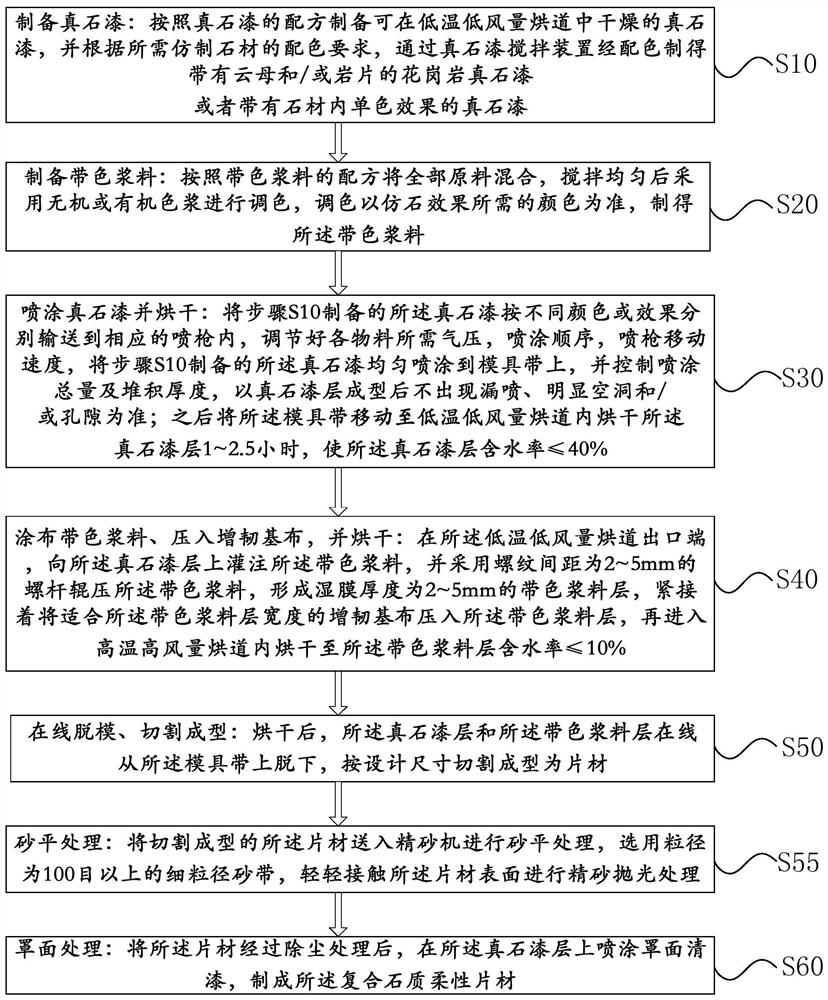

[0053] Some embodiments of the present invention, such as figure 1 As shown, a preparation method of a composite stone flexible sheet is provided, comprising the following steps:

[0054] Step S10, preparing real stone paint: prepare real stone paint that can be dried in a low-temperature, low-air volume drying tunnel according to the formula of real stone paint, and according to the color matching requirements of the required imitation stone, use a real stone paint mixing device to prepare a real stone paint with mica and / Or granite real stone paint of rock flakes or real stone paint with monochrome effect inside the stone;

[0055] Step S20, prepare the colored paste: mix all the raw materials according to the formula of the colored paste, mix them evenly, use inorganic or organic color paste to color the color, the color is based on the color required for the imitation stone effect, and the obtained Said colored paste;

[0056] Step S30, spraying real stone paint and dr...

Embodiment 1

[0088] Example 1: The method of the present application is used to prepare a composite stone flexible sheet on the fire surface.

[0089] Its production steps are:

[0090] 1. Prepare real stone paint for the surface layer:

[0091] The real stone paint formula is:

[0092] ⑴Monochrome real stone paint:

[0093]

[0094]

[0095] ⑵ Granite real stone paint:

[0096]

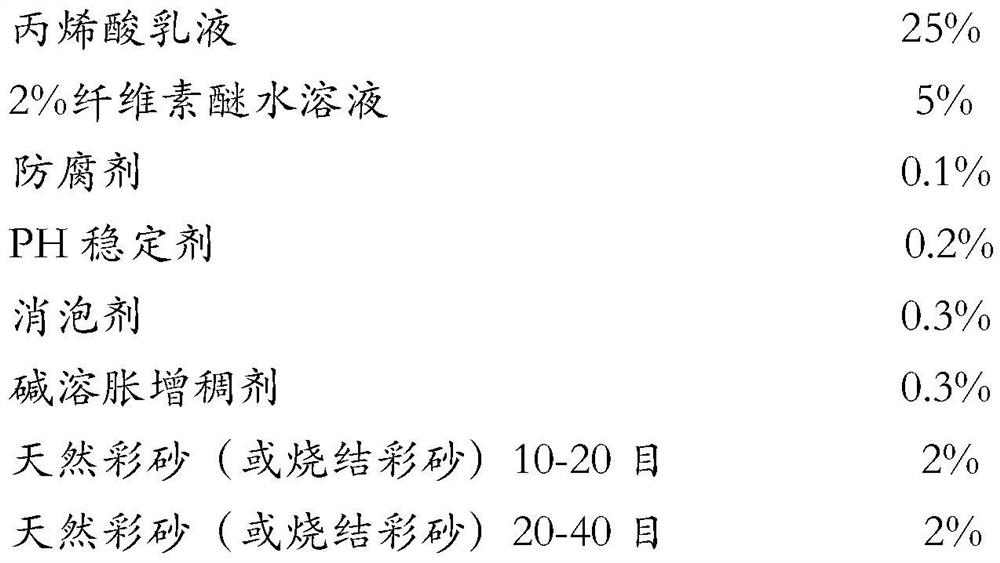

[0097] Pour the formula amount of acrylic emulsion or deionized water into the reaction kettle, turn on the real stone paint stirring tank, add 2% cellulose aqueous solution, preservative, PH stabilizer, defoamer, etc. at a time, stir evenly, and gradually increase the speed Stirring speed, add alkali swelling thickener (or polyurethane thickener) in turn, and adjust the viscosity to the required viscosity.

[0098] Put natural colored sand (or sintered colored sand) of various meshes into the reaction kettle in turn. After the formula is verified, it is determined, and it is stirred evenly in the r...

Embodiment 2

[0110] Example 2: Using the method of the present application to prepare a flat-pressed composite stone flexible sheet

[0111] The flat-pressed stone sheet refers to a composite stone flexible sheet that is smooth to the touch and has both concave-convex texture and clear lines obtained by using the fine sand process to process the fire-surface composite stone flexible sheet. Its production steps are:

[0112] 1. Prepare real stone paint for the surface layer:

[0113] The real stone paint formula is:

[0114] ⑴Monochrome real stone paint:

[0115]

[0116] ⑵ Granite real stone paint:

[0117]

[0118]

[0119] Note: Among them, if the flat-pressed stone sheet to be compared has the effect of flat marble, with the crystals shown by the stone, when preparing the real stone paint for the surface layer, prepare monochrome real stone paint and granite real stone paint; Monochrome real stone paint can be prepared when the flat marble does not show the crystal effect, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com