An antibacterial polycarbonate composite material and a preparing method thereof

A technology of polycarbonate and composite materials, applied in the field of antibacterial polycarbonate composite materials and their preparation, can solve the problems of loss of sterilization function, increase of material cost, loss of antibacterial properties, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

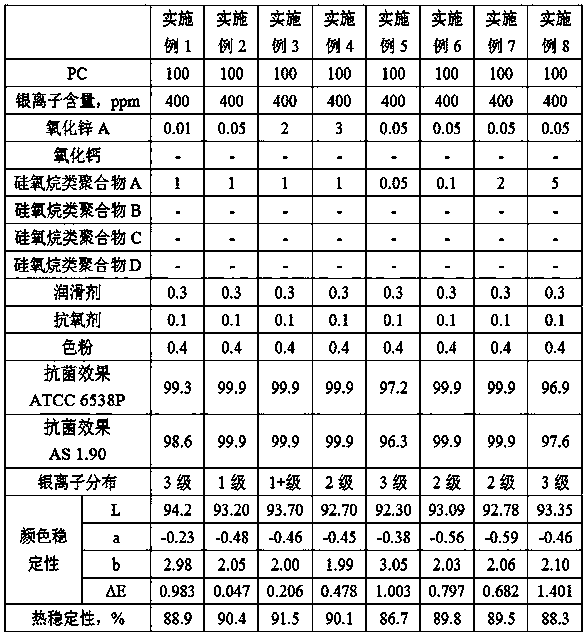

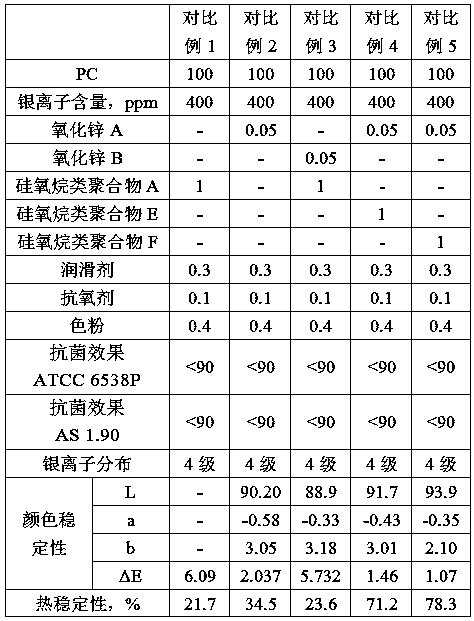

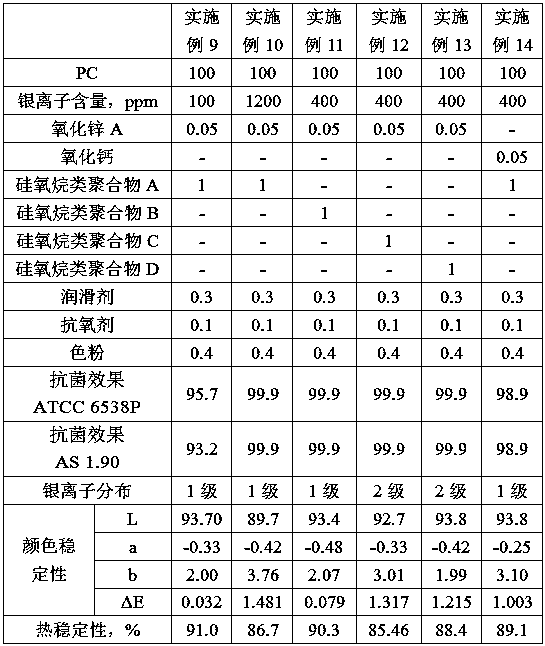

Examples

Embodiment Construction

[0034] The present invention is further illustrated by the following examples, but the present invention is not limited by the following examples.

[0035] The sources of raw materials used in the present invention are as follows, but are not limited by the following raw materials.

[0036] Silver ion source: Silver ion antibacterial agent, IKM50G, Japan Zeomic;

[0037] Zinc oxide A: Mitsubishi, D50=400nm;

[0038] Zinc oxide B: D50=5 microns;

[0039] Calcium Oxide: Merck, Germany, D50=400nm;

[0040] Silicone polymer A: molecular weight 200,000;

[0041] Silicone polymer B: molecular weight 300,000;

[0042] Silicone polymer C: molecular weight 150,000;

[0043] Silicone polymer D: molecular weight 350,000;

[0044] Silicone polymer E: molecular weight 100,000;

[0045] Silicone polymer F: molecular weight 500,000;

[0046] Lubricant: POLY TS 30A Korean Pacific Chemical;

[0047] Antioxidant: 2112, Adico;

[0048] Toner: Titanium Dioxide 2233, German Connors;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com