Marine-climate-resistant primer coat powder coating material and preparation method thereof

A powder coating, marine technology, applied in the field of primer powder coating and its preparation, can solve the problems of coating peeling, damage, reliability reduction, etc., achieve salt spray resistance and water resistance, good coating appearance, excellent corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Examples are further listed below to describe the present invention in detail. It should also be understood that the following examples are only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention. Some non-essential improvements and adjustments made by those skilled in the art according to the principles set forth in the present invention all belong to the present invention scope of protection. The specific process parameters and the like in the following example are only an example of the appropriate range, that is, those skilled in the art can make a selection within the appropriate range through the description herein, and are not limited to the specific data in the example below.

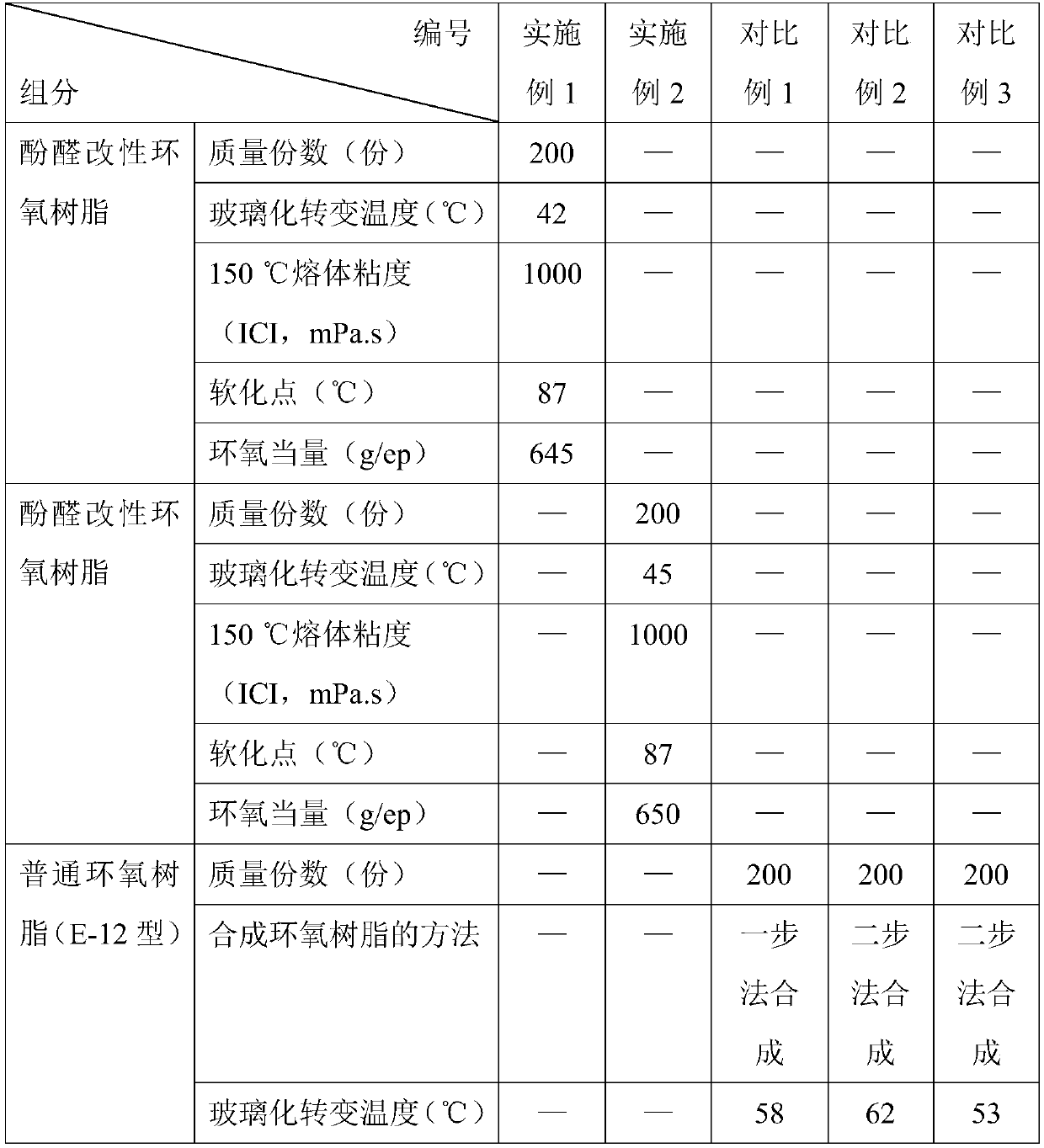

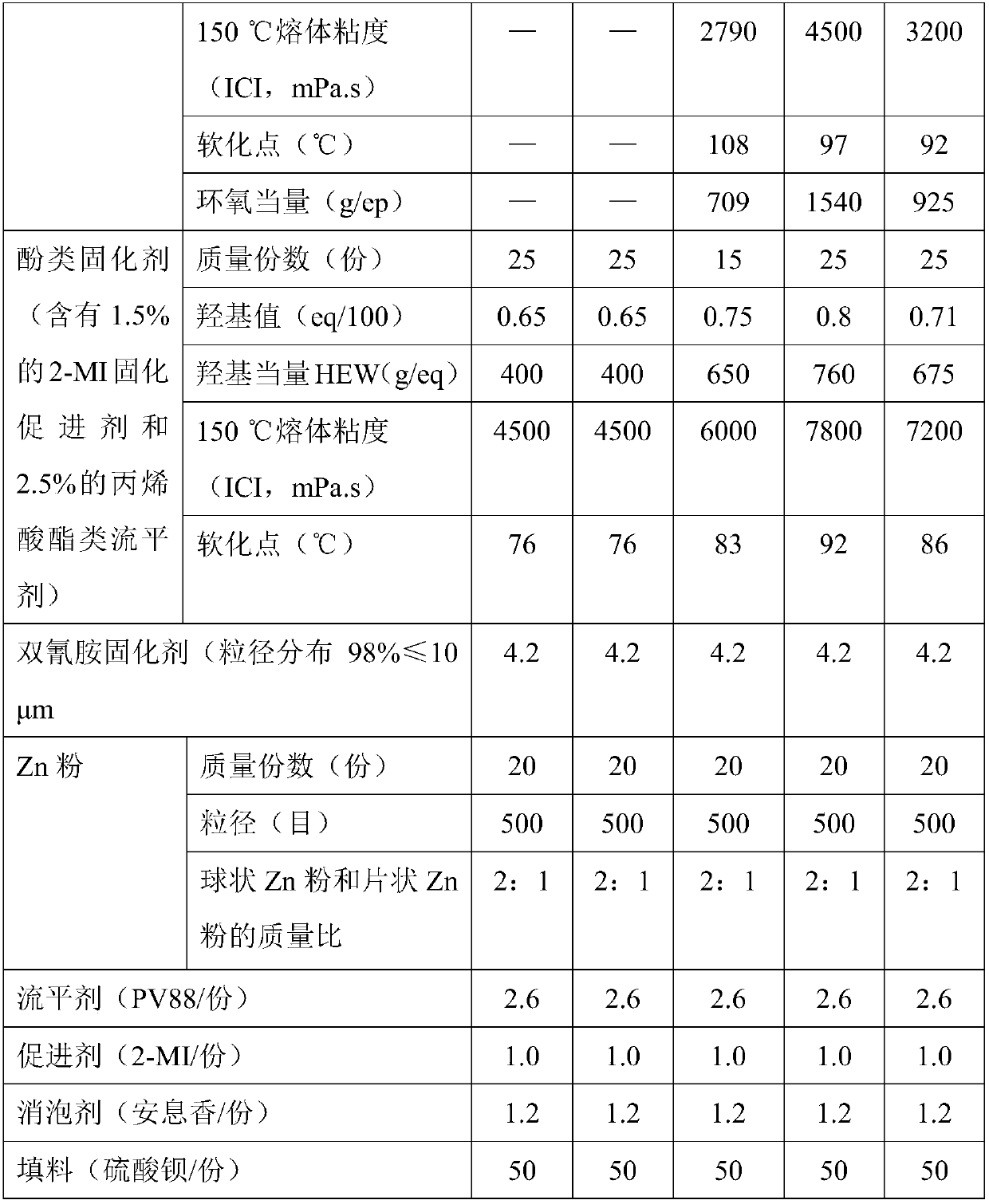

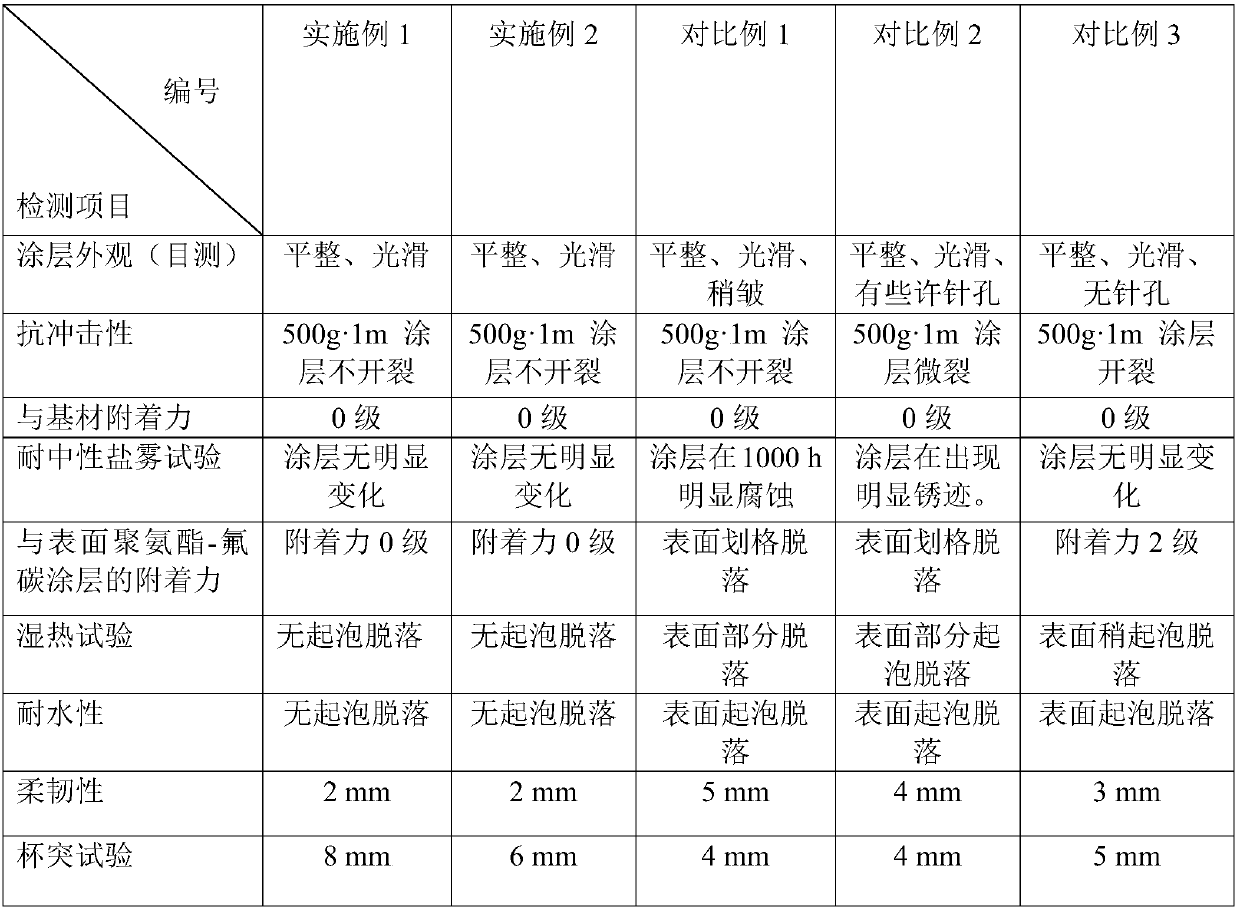

[0051] Below in conjunction with embodiment and comparative example the present invention is described in detail, and the component of the powder coating of each embodiment and comparative example sees ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap