Method for increasing organic load of anaerobic fermentation

An anaerobic fermentation and organic load technology, applied in the field of environmental engineering, can solve the problems of collapse of the methane production system, decline of methane production, and difficulty in recovering the activity of methanogens, so as to accelerate the methane production rate, improve the fermentation capacity, and shorten the digestion period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

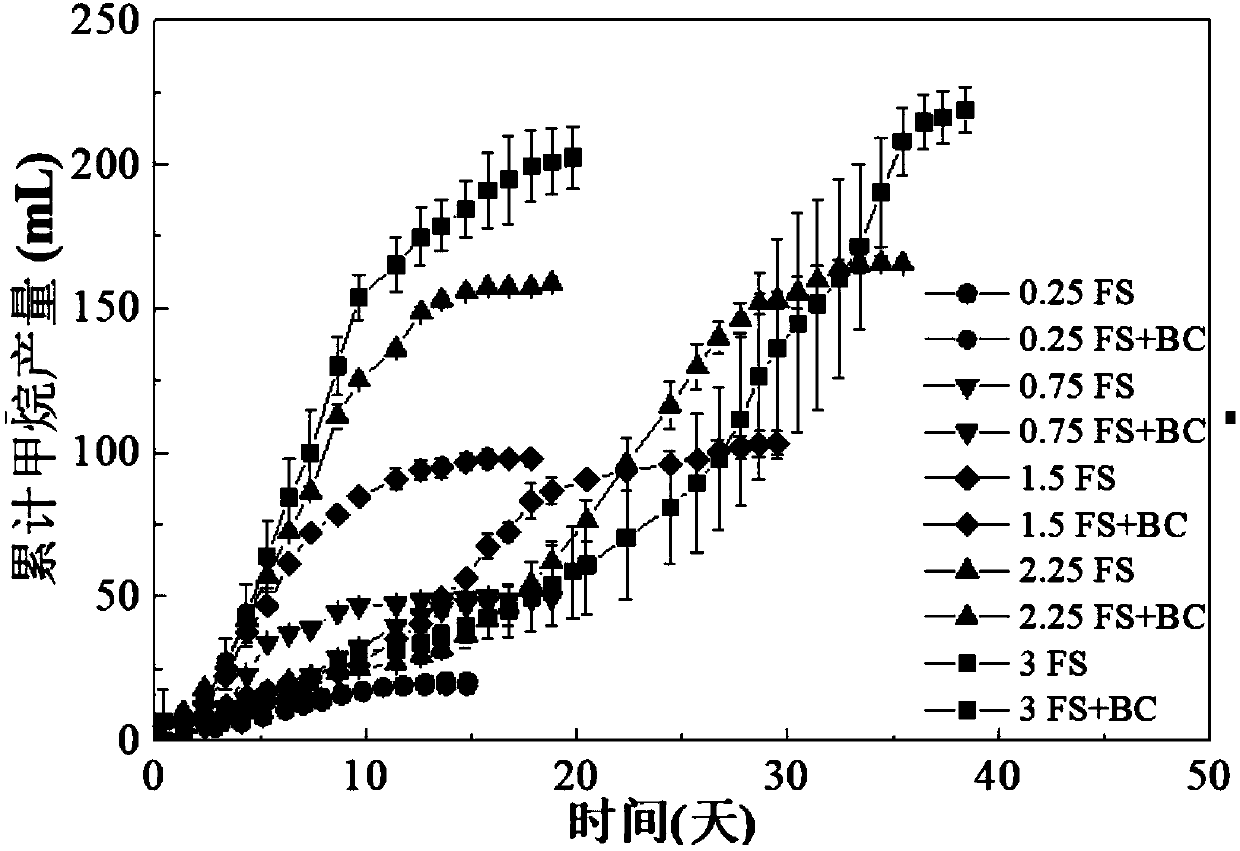

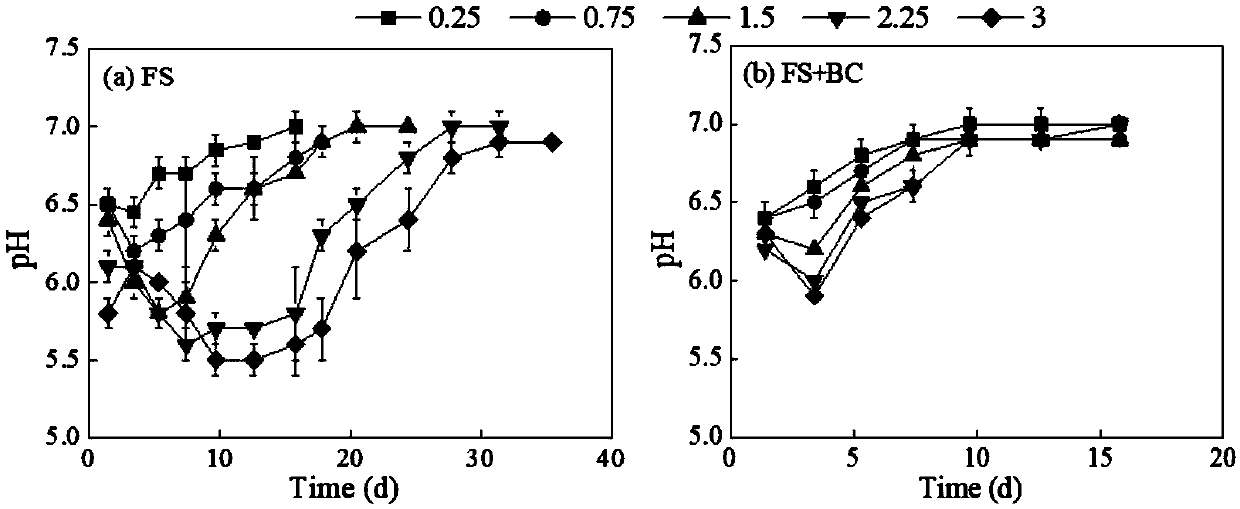

[0016] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

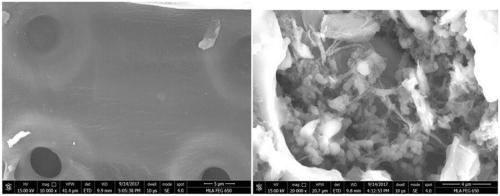

[0017] (1) The preparation method of biochar: put the sawdust into the crucible, compact it to reduce the pores between the sawdust, and put the solid waste such as the sawdust in an anoxic environment at 500°C, and control the temperature rise to 10-15°C / min After the temperature reaches 500°C, maintain it for 2 hours, sieve it after cooling down, and control the pore size between 0.25mm-1mm, and store it in a dry place for later use.

[0018] (2) Fermentation substrate and parameters of anaerobic seed sludge: The substrate used in this study is food waste and residual sludge. ), potatoes (20%), cabbage (20%), carrots (13.8%), pork (10%), chicken (2%), eggs (5%), oil (1%), salt (0.2%), The remaining sludge is taken from the dewatered sludge of the secondary settling tank of the sewage plant. The food waste and the remaining sludge are prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com