Processing method of calorimetric curve baseline displacement during thermal analysis of propellant and explosive samples

A technology of baseline displacement and explosives, applied in the field of explosives, can solve the problems of the influence of the shape of the kinetic curve, the error of different integration points, and the baseline displacement, so as to improve the accuracy and precision, avoid calorimetric errors, and eliminate the baseline displacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

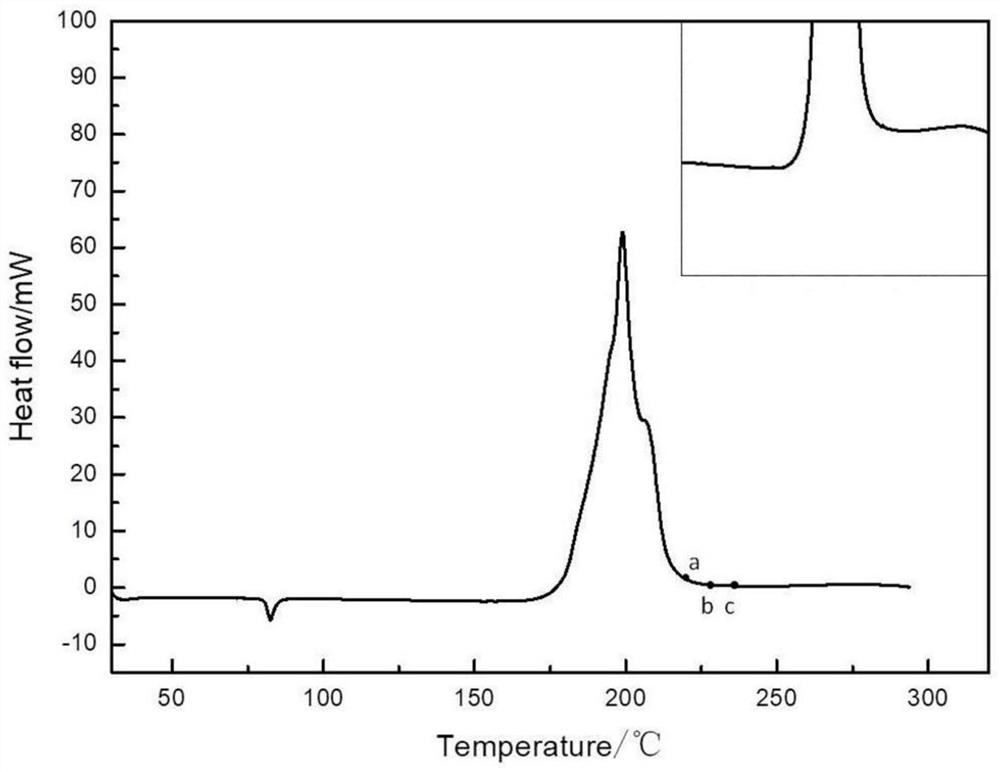

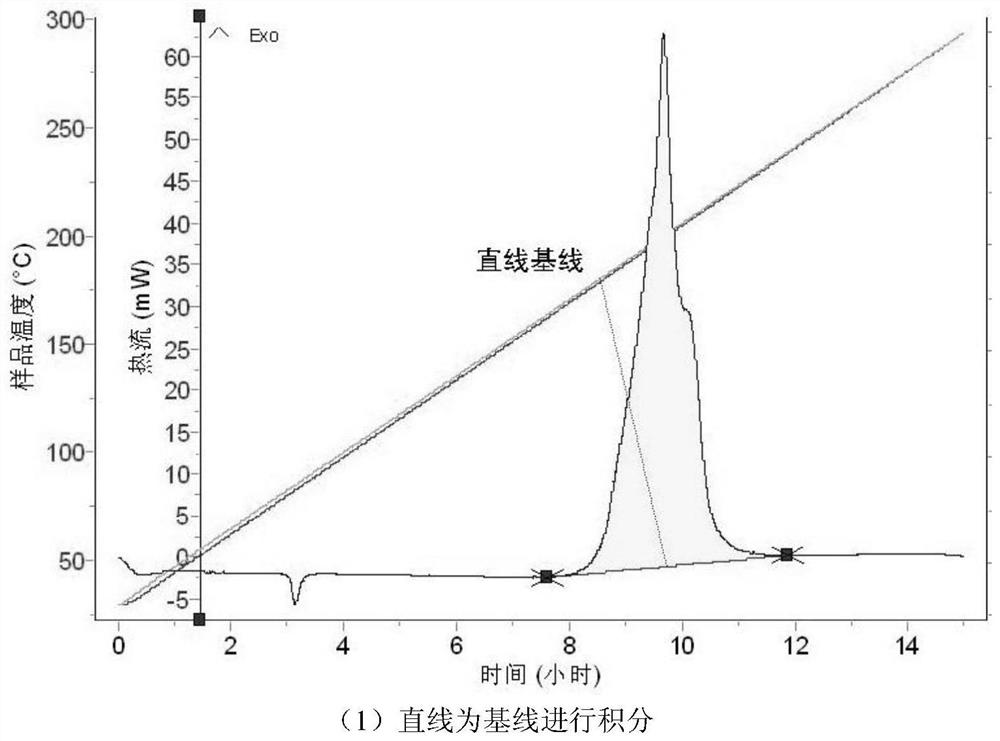

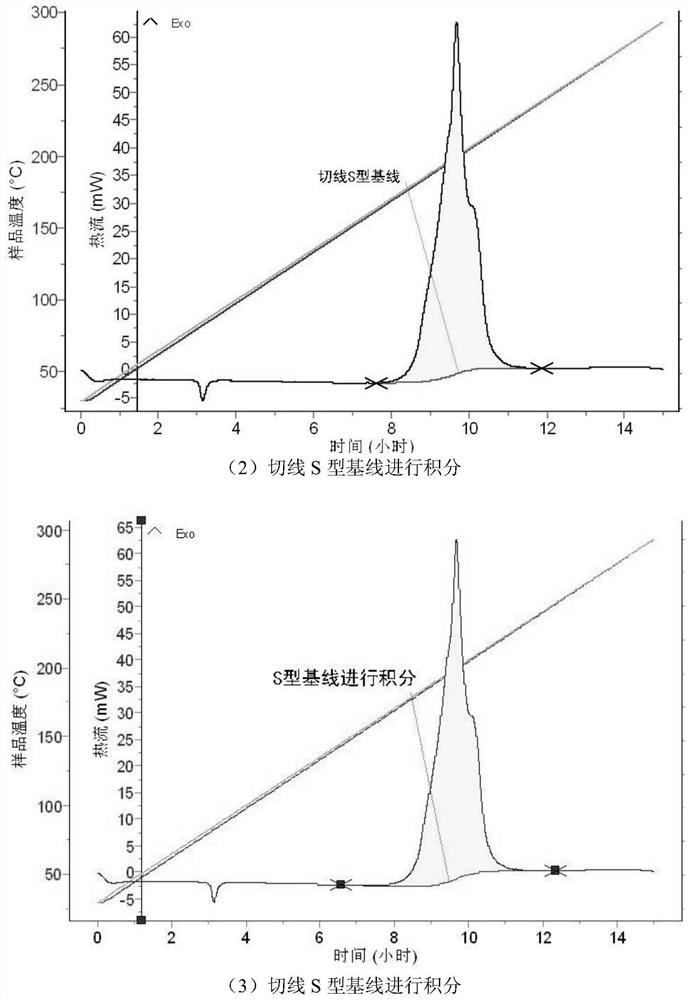

[0032] Using the microcalorimetry method to study the thermal decomposition calorimetry curve of a propellant sample, the experimental results appear as follows: figure 1 In the case shown, the baselines before and after the thermal decomposition calorimetry curves are inconsistent. The method provided according to the present invention eliminates the baseline shift from the following steps.

[0033] 1. Test the specific heat capacity of the sample

[0034] Using a C80 microcalorimeter, weigh 100 mg of the propellant and explosive sample and put it into the sample cell. Under the condition of 0.15°C / min, within the temperature range where no phase transition occurs, study the change law of the specific heat capacity of the sample with temperature. According to the specific heat capacity expression Calculate the specific heat capacity within the calorimetric temperature range, and obtain the change law of the specific heat capacity of the propellant and explosive samples with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com