Gas and dust explosion characteristic testing device

A characteristic testing and gas technology, applied in measuring devices, fuel testing, instruments, etc., can solve the problems of not being suitable for field tests, unable to monitor temperature changes, not installing temperature sensors, etc., achieving good portability, easy maintenance, and portability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

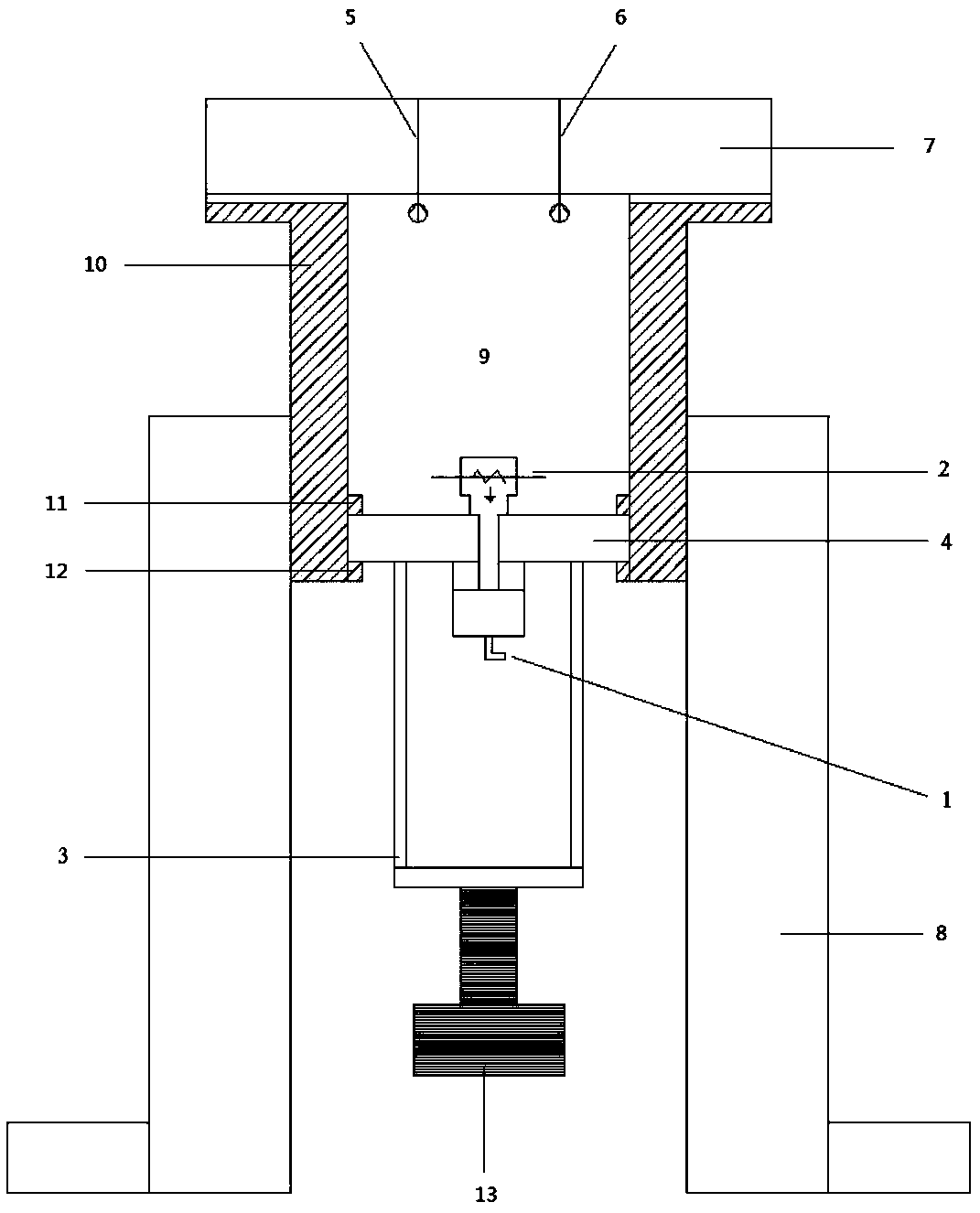

[0027] A gas (or vapor) or dust explosion characteristic test device is adopted, the structure of which is as follows: figure 1 As shown, the test device includes an explosion cavity 9, which is a closed space formed by a top cover 7, a cavity shell 10 and a moving piston 4, and the explosion cavity 9 is supported by a support 8, so The above-mentioned top cover 7 is equipped with a temperature sensor 5 and a pressure sensor 6, the support 3 and the spring-type push-pull rod 13 are connected under the described moving piston 4, and the moving piston 4 promoted by the spring-type push-pull rod 13 moves in the explosion chamber 9 , the moving range is controlled by the upper limiter 11 and the lower limiter 12, and the moving piston 4 is also provided with an electric ignition device 2 and a solenoid valve sampling system 1.

[0028] When performing a gas (or vapor) or dust test, adjust the spring push-pull rod 13, move the piston 4 to the corresponding position, form a negative...

Embodiment 2

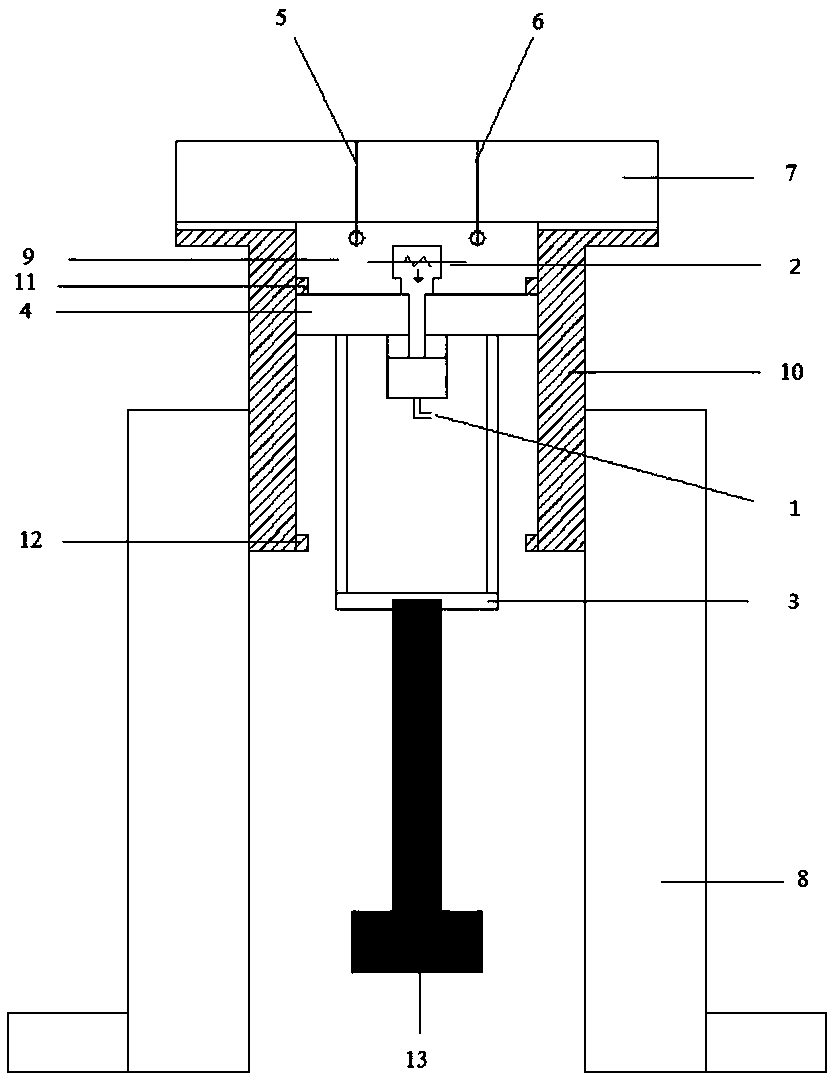

[0031] A gas (or vapor) or dust explosion characteristic testing device is adopted, the structure of which is as follows: figure 2 As shown, the structure is the same as that of Embodiment 1, the difference is that figure 2The device shown in is the structure diagram of the device before the explosion reaction occurs. When the explosion occurs, the gas in the reaction chamber expands and the pressure rises to form figure 1 situation. The pressure state in the reaction chamber can be obtained intuitively by observing the position of the moving piston.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com