Fabrication method of 3D high-density interconnected PoP plastic package device

A high-density interconnection and device technology, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., to achieve the effects of feasibility, flexible packaging, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

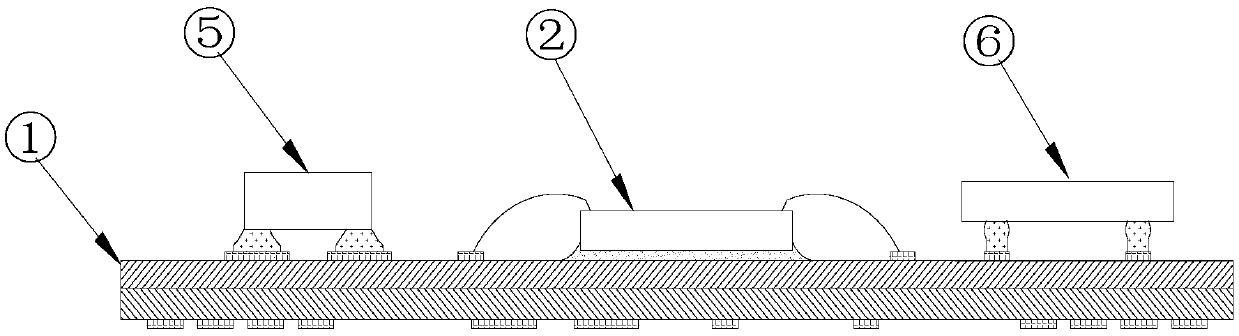

[0043] Embodiment 1: One-sided interconnection PoP packaging form, including the following steps:

[0044] Such as Picture 1-1 As shown, step 1. Select a substrate 1, and perform flip chip 6 placement, SMT device 5 placement and other chip 2 placement bonding on the front of the substrate 1;

[0045] The substrate 1 in this embodiment 1 includes an MCM substrate.

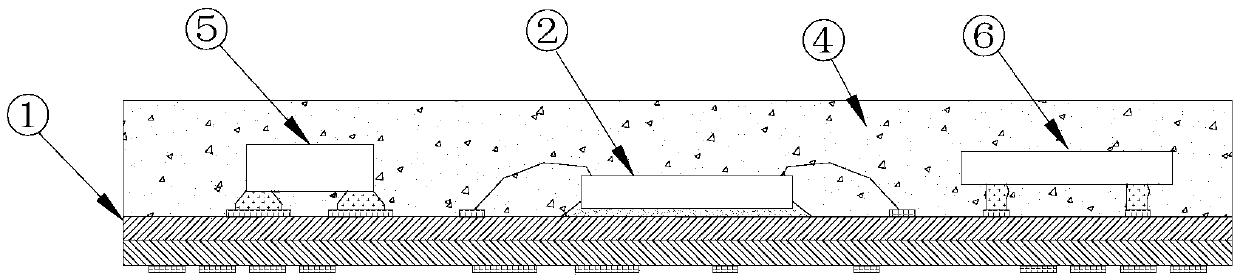

[0046] Such as Figure 1-2 As shown, step 2. Encapsulate the front of the substrate 1 with a plastic encapsulant 4 to complete the front encapsulation;

[0047] Such as Figure 1-3 As shown, step 3. On the back of the substrate 1, perform flip chip 6 mounting, SMT device 5 mounting, and copper pillar 3 pillar planting; in the process of pillar copper pillar 3, first apply solder paste on the substrate 1 at low temperature , using the reflow process after brushing the solder paste, and then reflow soldering the copper pillar 3;

[0048] Here, according to the specific application situation, other chips 2 can als...

Embodiment 2

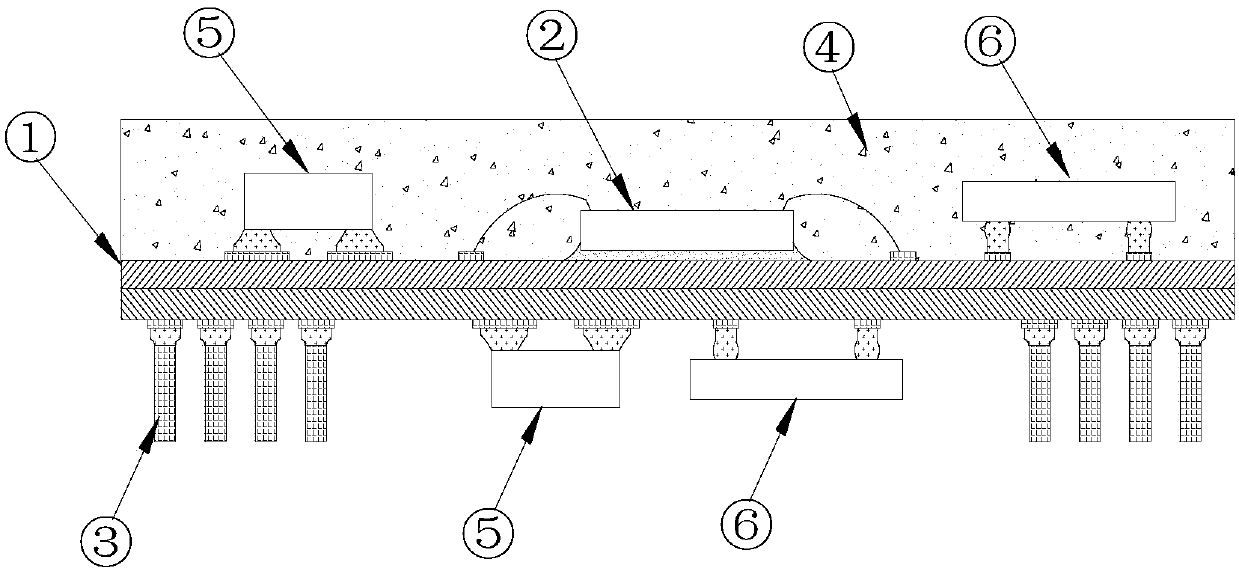

[0053] Embodiment 2: The double-sided interconnection PoP encapsulation form includes the following steps:

[0054] Such as diagram 2-1 As shown, step 1: chip 2 patch bonding and copper pillar 3 pillar planting are performed on the front of substrate 1; here, according to actual application conditions, flip chip 6 mounting, SMT device 5 mounting, etc. can be performed as appropriate;

[0055] Such as Figure 2-2 As shown, step 2: complete the plastic encapsulation on the front of the substrate 1;

[0056] Such as Figure 2-3 As shown, step 3: complete flip chip 6 placement, SMT device 5 placement and column planting process on the back of the substrate 1;

[0057] In the process of planting the copper pillar 3, first apply solder paste on the substrate 1 at low temperature, use the reflow process after brushing the solder paste, and then reflow solder the copper pillar 3;

[0058] Here, according to the specific application situation, other chips 2 can also be bonded;

...

Embodiment 3

[0063] Such as image 3 As shown, the 3D high-density interconnected PoP plastic packaged device stacked in the device includes the following steps:

[0064] Stack the single-sided interconnected PoP packaged device in real-time example 1 and the double-sided interconnected PoP packaged device in embodiment 2, and first tear off the protective film 8 on one side of the double-sided interconnected PoP packaged device to expose the 3 ends of the copper pillars , and then solder the solder ball 7 of the single-sided interconnected PoP packaged device to the exposed copper column end, thus completing the stacking of the single-sided interconnected PoP packaged device and the double-sided interconnected PoP packaged device;

[0065] The stacking form in Embodiment 3 is not limited to stacking two devices, nor is it limited to stacking single-sided and double-sided devices, but also stacking multiple single-sided / double-sided interconnected PoP packaged devices.

[0066] In the for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com