A positive pole piece and a secondary battery using the positive pole piece

A technology for positive pole pieces and positive current collectors, which is applied in the field of secondary batteries, and can solve problems such as the inability to prevent the exposure of aluminum foil and the inability to completely eliminate the short circuit of the positive current collector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] There are two main methods for the preparation of grafted polymers:

[0048] Method 1: Activate a pre-polymerized polymer by chemical or physical chemical methods to generate active centers (indicated by *) on the main chain, which can be free radicals, positive or negative ions. Then it initiates the polymerization of monomer M to form a graft copolymer. This method is called the method of grafting branches on the polymer.

[0049] Method 2: Adding a graft monomer while initiating the polymerization of the main chain monomer, so that the main chain monomer and the graft-modified monomer M are polymerized simultaneously to form a graft-modified polymer.

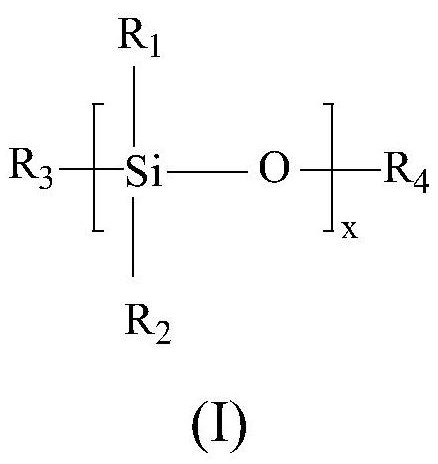

[0050] Wherein, M is used as a graft-modified monomer, and if it has polymerization reaction functional groups such as C=C and -OH, and can undergo polymerization reaction, method 2 can be adopted. If M itself does not contain a group capable of participating in the polymerization reaction, the first method is adopted...

Embodiment 1

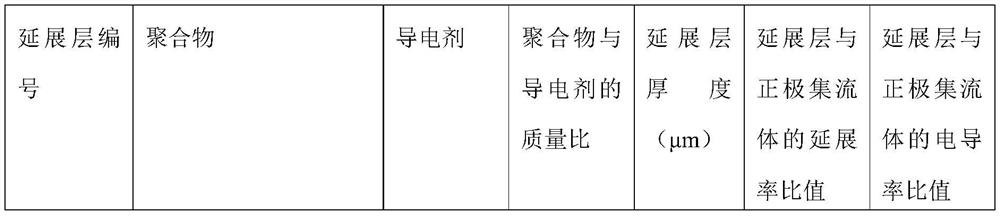

[0090] Extension layer preparation

[0091] After mixing the polymer and the conductive agent, adding a solvent, stirring evenly to obtain the extension layer slurry, and then coating the extension layer slurry on the surfaces of both sides of the positive current collector, and drying to obtain the extension layers 1-13. Wherein the oily polymer uses N-methylpyrrolidone as a solvent, and the water-based polymer uses deionized water as a solvent. The positive current collector is made of aluminum foil with a thickness of 12 μm. The types of polymer and conductive agent, the mass ratio of the two added, the thickness of the extension layer, the ratio of the extension rate of the extension layer to the positive electrode collector, and the conductivity ratio of the extension layer to the positive electrode collector are shown in Table 1. In the polymer column, take "styrene-butadiene rubber-g-octadecene, 6.3:1" as an example, which means that the mass ratio of styrene-butadien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com