Micro-fuel cell suitable for high-concentration methanol and discharging method of micro-fuel cell

A micro fuel cell, high-concentration technology, used in fuel cells, portable system fuel cells, circuits, etc., can solve the problems of low energy density of fuel cell systems, inability to use high concentrations, aggravated methanol penetration, etc., to achieve fuel supply and products. Smooth discharge, improved current collection effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

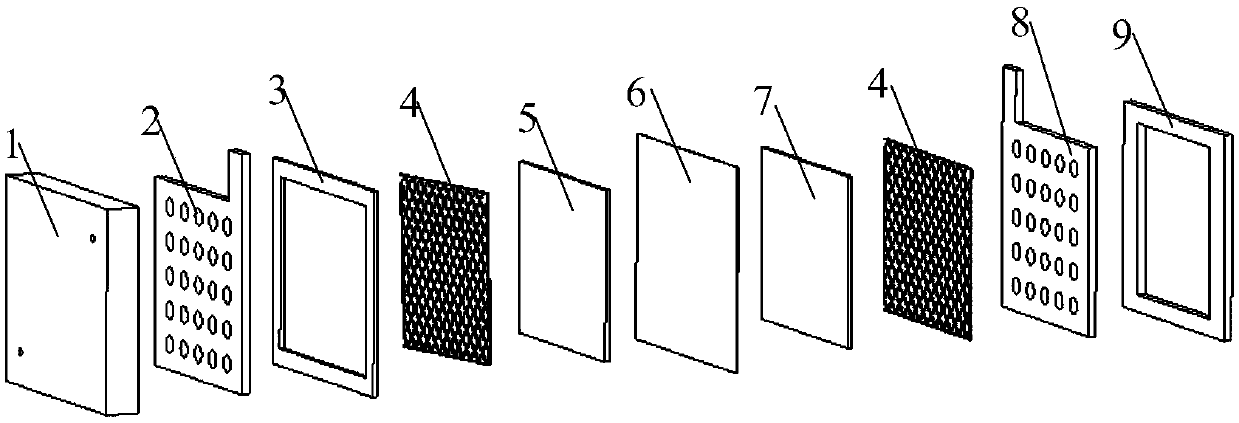

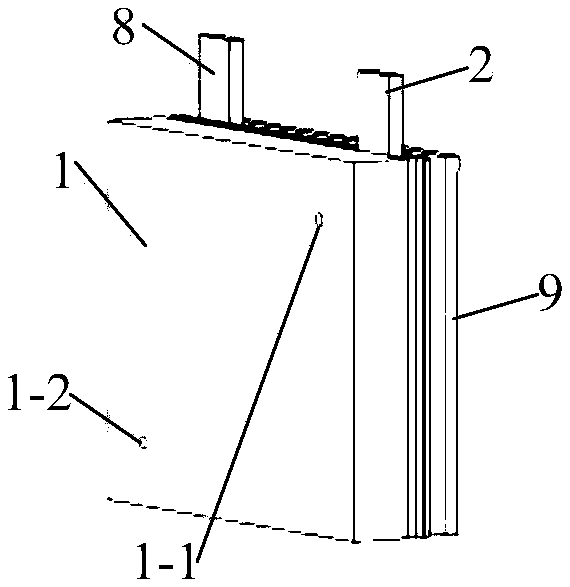

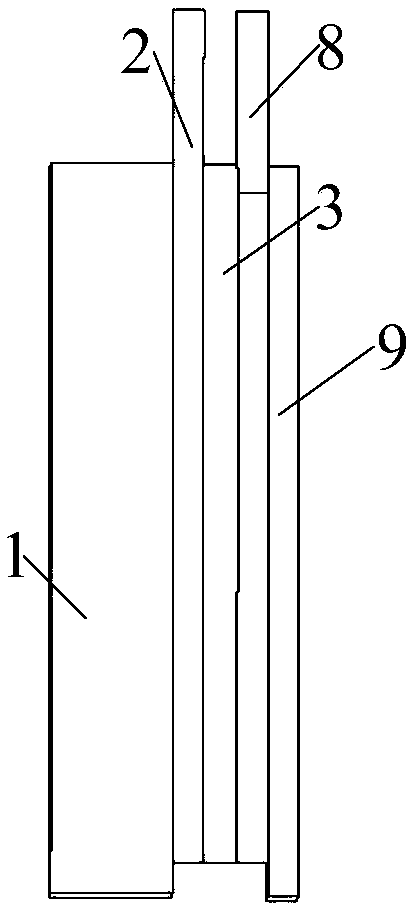

[0033] Such as figure 1 , 2 As shown in and 3, a micro fuel cell suitable for high-concentration methanol includes an anode outer flow field plate 1, an anode plate 2, a membrane electrode, a cathode plate 8 and a cathode end plate 9 arranged in sequence. Both the anode external flow field plate 1 and the cathode end plate 9 are made of ABS material.

[0034] Such as figure 1 , 2 As shown in and 4, a serpentine flow channel groove is opened on the inner surface of the anode outer flow field plate 1. The serpentine runner groove does not penetrate through the anode outer flow field plate 1 . The serpentine runner groove is composed of m horizontal grooves and m-1 connecting grooves, m=5. The m transverse grooves parallel to each other are arranged at equal intervals in turn. Any two adjacent transverse grooves are connected through a connecting groove. The two connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com